20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

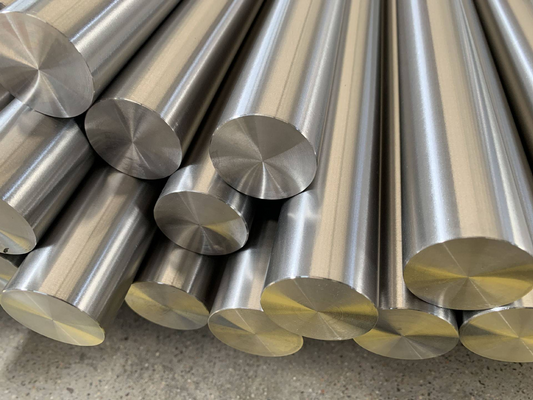

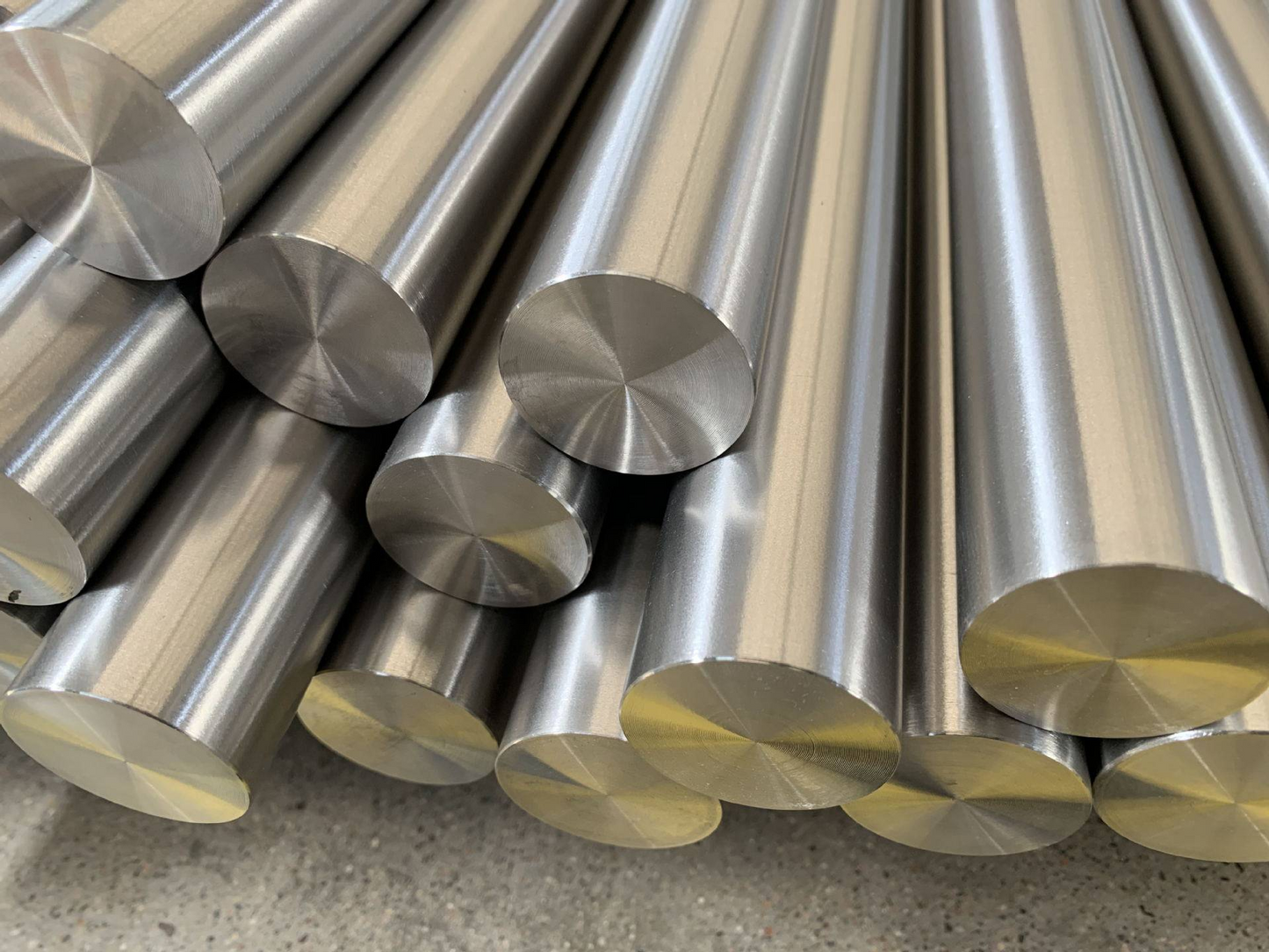

Product Overview

الخصائص المعدنية

EN 100CrMo7 هو فولاذ محامل ذو صلابة كاملة مع قابلية تصلب استثنائية بسبب محتواه من الكروم والموليبدينوم. يوفر محتوى الكربون العالي (0.95-1.05%) الصلابة اللازمة لتطبيقات المحامل، بينما يعزز الكروم (1.35-1.65%) مقاومة التآكل وقابلية الصلابة. يحسن الموليبدينوم (0.15-0.25%) المتانة ويقلل من هشاشة التخمير، مما يجعل هذا الفولاذ مثاليًا لتطبيقات المحامل ذات الضغط العالي.

عملية المعالجة الحرارية

تبدأ عملية المعالجة الحرارية الخاصة بـ MetalZenith بالتسخين الكروي عند 750-780°C لتحسين قابلية التشغيل. يتم التصلب عند 820-860°C يتبعه التبريد بالزيت لتحقيق بنية مارتنسيتية. يوفر التخمير عند 150-200°C التوازن الأمثل بين الصلابة (60-64 HRC) والمتانة. تضمن معدلات التبريد المتحكم بها وإدارة الأجواء الحد الأدنى من التشوه والبنية المجهرية المثلى.

عملية التصنيع

تبدأ الإنتاج بصهر فرن القوس الكهربائي يتبعه علم المعادن في القالب للتحكم الدقيق في الكيمياء. يزيل التفريغ الفراغي الهيدروجين ويقلل من محتوى الشوائب. يتبع الصب المستمر أو صب القضبان بالدرفلة الساخنة أو التشكيل لتحقيق الأبعاد المطلوبة. تضمن عمليات التبريد والمعالجة الحرارية المتحكم بها من MetalZenith خصائص متسقة في جميع أنحاء مقطع المادة.

معايير الجودة والاختبار

تخضع جميع منتجات EN 100CrMo7 للاختبار الشامل بما في ذلك التحليل الكيميائي، والتحقق من الخصائص الميكانيكية، والفحص بالموجات فوق الصوتية، وتقييم النظافة وفقًا لمعيار ASTM E45. يحقق اختبار التعب أداء عمر المحامل. تحافظ MetalZenith على تتبع كامل من المواد الخام حتى الفحص النهائي، مع تقديم شهادات الامتثال لجميع الشحنات. يضمن نظام إدارة الجودة لدينا أداءً متسقًا يتوافق مع معايير صناعة المحامل الدولية.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| الكربون (C) | 0.95 - 1.05 |

| السيليكون (Si) | 0.15 - 0.35 |

| المنغنيز (Mn) | 0.25 - 0.45 |

| الفوسفور (P) | ≤ 0.025 |

| الكبريت (S) | ≤ 0.015 |

| الكروم (Cr) | 1.35 - 1.65 |

| الموليبدينوم (Mo) | 0.15 - 0.25 |

| النيكل (Ni) | ≤ 0.30 |

| النحاس (Cu) | ≤ 0.25 |

| الألمنيوم (Al) | ≤ 0.050 |

⚙️ Mechanical Properties

| الخاصية | القيمة |

|---|---|

| قوة الشد (مُعالج) | 750 - 950 ميغاباسكال |

| قوة العائد (مُعالج) | ≥ 450 ميغاباسكال |

| التمدد (مُعالج) | ≥ 10% |

| تقليل المساحة (مُعالج) | ≥ 35% |

| الصلابة (مُعالج) | ≤ 255 HB |

| الصلابة (مُقسى ومُعالج) | 60 - 64 HRC |

| طاقة الصدمة (مُعالج، 20°م) | ≥ 25 جول |

| حد التعب (انحناء دوار) | 450 - 550 ميغاباسكال |

| معامل يونغ | 210 جيجاباسكال |

| نسبة بواسون | 0.27 - 0.30 |

🔬 Physical Properties

| الخاصية | القيمة |

|---|---|

| الكثافة | 7.85 g/cm³ |

| نقطة الانصهار | 1420 - 1460°C |

| الموصلية الحرارية (20°C) | 42 W/m·K |

| معامل التمدد الحراري (20-100°C) | 11.5×10-6/K |

| معامل التمدد الحراري (20-200°C) | 12.1×10-6/K |

| السعة الحرارية النوعية | 460 J/kg·K |

| المقاومة الكهربائية (20°C) | 0.25 µΩ·m |

| نفاذية مغناطيسية | مغناطيسي حديدي |

| درجة حرارة كوري | ~760°C |

| الانتشار الحراري | 11.6 mm²/s |

📏 Product Specifications

| المواصفات | التفاصيل |

|---|---|

| الأشكال المتاحة | أشرطة دائرية، أشرطة مربعة، أشرطة مسطحة، حلقات مطروقة، أنابيب، سلك |

| قطر الشريط الدائري | 10 - 500 مم |

| حجم الشريط المربع | 10×10 - 200×200 مم |

| أبعاد الشريط المسطح | السماكة: 5-100 مم، العرض: 20-300 مم |

| قطر السلك | 0.5 - 20 مم |

| الطول | حتى 12 متر (قياسي)، أطوال مخصصة متاحة |

| تشطيب السطح | أسود، مشغول، مصقول، مصقول |

| تحمل الأبعاد | h9 إلى h11 (قياسي)، h6 إلى h8 (دقيق) |

| الامتثال للمعايير | EN 10132-4، ASTM A295، JIS G4805، DIN 17230 |

| حالة المعالجة الحرارية | مخمد، متكلس، مقسى ومقسى |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing 100CrMo7

تكنولوجيا الصهر بالفراغ المتقدمة

تستخدم MetalZenith عمليات الصهر بالتحريض الفراغي المتقدم (VIM) وإعادة الصهر بالقوس الفراغي (VAR) لإنتاج EN 100CrMo7 مع نظافة استثنائية وتجانس. تضمن عملية الصهر في جو محكم التحكم القضاء على الشوائب وتوزيع الكربيد بشكل مثالي لأداء ممتاز في المحامل.

تحكم دقيق في معالجة الحرارة

تتميز مرافق المعالجة الحرارية التي تتحكم فيها الكمبيوتر بأفران متعددة المناطق مع مراقبة دقيقة لدرجة الحرارة والتحكم في الجو. تحقق عمليات التبريد والتسخين الخاصة بـ MetalZenith ملفات صلابة متسقة وبنية دقيقة مثالية لأقصى عمر تعب وإستقرار أبعاد.

اختبار شامل وتخصيص

MetalZenith تقدم تصنيفًا كاملاً للمواد بما في ذلك تقييم النظافة، وتحليل حجم الحبيبات، واختبار التعب. نحن نقدم تعديلات كيميائية مخصصة، ومعالجات حرارية متخصصة، وخدمات تشغيل دقيقة لتلبية متطلبات التطبيقات المحددة مع وثائق تتبع كاملة.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات