20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

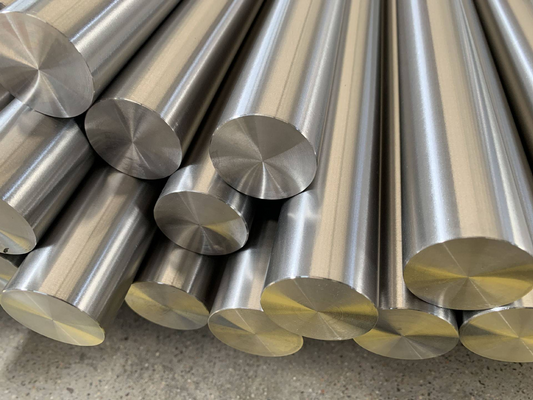

Product Overview

خصائص المعادن

AISI M50 هو فولاذ أدوات ذو صلابة ثانوية مع هيكل كربيدي معقد يوفر مقاومة استثنائية للتآكل وثبات حراري. يحتوي الفولاذ على كربيدات أولية من الفاناديوم (VC) والموليبدينوم (Mo2C)، بالإضافة إلى كربيدات الكروم (M7C3 و M23C6) التي تساهم في أدائه الممتاز عند درجات الحرارة العالية. يتم تحقيق التوزيع الدقيق والمتساوي لهذه الكربيدات من خلال عملية صهر VIM/VAR التي تتحكم فيها MetalZenith.

عملية المعالجة الحرارية

تستخدم MetalZenith بروتوكولات معالجة حرارية دقيقة لـ AISI M50، بما في ذلك الأوستنيتيزنج عند 1065-1095°C، تليها التبريد بالزيت أو الهواء لتحقيق الصلابة المثلى. يتم إجراء التخمير عند 480-540°C لتطوير التوازن المطلوب بين الصلابة والصلابة. تضمن أفراننا ذات الجو المتحكم فيه نتائج متسقة وتمنع إزالة الكربون. قد يتم تطبيق دورات تخمير متعددة لتحقيق متطلبات صلابة محددة مع الحفاظ على الاستقرار الأبعاد.

تميز عملية التصنيع

تبدأ عملية التصنيع لدينا بمواد خام مختارة بعناية تخضع لعملية صهر بالتحريض في الفراغ لضمان تجانس كيميائي. يتم بعد ذلك إعادة صهر الفولاذ المنصهر في قوس فراغي للقضاء على الشوائب وتحسين النظافة. يتم إجراء عمليات التشكيل الساخن اللاحقة ضمن نطاقات درجات حرارة متحكم فيها لتحسين هيكل الحبيبات. يتم مراقبة جميع خطوات المعالجة باستخدام أنظمة التحكم في العمليات المتقدمة للحفاظ على جودة متسقة.

معايير الجودة والاختبار

تلتزم إنتاج AISI M50 من MetalZenith بمعايير جودة الطيران الصارمة بما في ذلك مواصفات AMS 6490/6491. تشمل الاختبارات الشاملة التحليل الكيميائي عبر مطيافية الانبعاث الضوئي، والتحقق من الخصائص الميكانيكية من خلال اختبارات الشد والصلابة، والفحص بالموجات فوق الصوتية للتأكد من السلامة الداخلية، والفحص المعدني للتحقق من البنية المجهرية. يرافق كل حرارة تقارير اختبار معتمدة ووثائق تتبع كاملة تلبي متطلبات AS9100D.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| الكربون (C) | 0.78 - 0.88 |

| المنغنيز (Mn) | 0.15 - 0.35 |

| السيليكون (Si) | 0.15 - 0.35 |

| الفوسفور (P) | ≤ 0.025 |

| الكبريت (S) | ≤ 0.010 |

| الكروم (Cr) | 3.75 - 4.50 |

| الموليبدينوم (Mo) | 4.00 - 4.50 |

| الفاناديوم (V) | 0.90 - 1.30 |

| النيكل (Ni) | ≤ 0.30 |

| النحاس (Cu) | ≤ 0.25 |

| الألمنيوم (Al) | ≤ 0.035 |

| التيتانيوم (Ti) | ≤ 0.035 |

⚙️ Mechanical Properties

| الخاصية | القيمة |

|---|---|

| قوة الشد (مُعالج ومُقسى) | 2070 - 2415 ميغاباسكال |

| قوة العائد (0.2% انحراف) | 1725 - 2070 ميغاباسكال |

| التمدد | 8 - 12% |

| تقليل المساحة | 25 - 35% |

| الصلابة (مُعالج ومُقسى) | 60 - 65 HRC |

| طاقة الصدمة (شاربي V-notch) | 15 - 25 جول |

| قوة التعب (10&sup7; دورة) | 900 - 1100 ميغاباسكال |

| معامل المرونة | 210 جيجاباسكال |

| نسبة بواسون | 0.27 - 0.30 |

| قوة الضغط | 2760 - 3100 ميغاباسكال |

| قوة القص | 1380 - 1550 ميغاباسكال |

🔬 Physical Properties

| الخاصية | القيمة |

|---|---|

| الكثافة | 8.15 جرام/سم³ |

| نقطة الانصهار | 1425 - 1455°م |

| الموصلية الحرارية (20°م) | 24.3 واط/م·ك |

| الموصلية الحرارية (315°م) | 28.5 واط/م·ك |

| معامل التمدد الحراري (20-100°م) | 10.8×10-6/ك |

| معامل التمدد الحراري (20-315°م) | 12.2×10-6/ك |

| السعة الحرارية النوعية | 460 جول/كغ·ك |

| المقاومة الكهربائية (20°م) | 0.52 µΩ·م |

| نفاذية مغناطيسية | مغناطيسي حديدي |

| درجة حرارة كوري | 760°م |

| الانتشار الحراري (20°م) | 6.5×10-6 م²/ث |

📏 Product Specifications

| المواصفات | الخيارات المتاحة |

|---|---|

| أشكال المنتجات | قضبان دائرية، قضبان مربعة، قضبان مسطحة، حلقات مطروقة، ألواح، صفائح |

| قطر القضيب الدائري | 6mm - 500mm |

| حجم القضيب المربع | 10mm - 300mm |

| سمك اللوحة | 5mm - 200mm |

| سمك الورقة | 0.5mm - 5mm |

| الطول | حتى 6000mm (أطوال مخصصة متاحة) |

| المعايير | ASTM A295، AMS 6490، AMS 6491، SAE J437 |

| تشطيب السطح | مدرفل على الساخن، مسحوب على البارد، مشغول، مصقول، مصقول |

| تحمل الأبعاد | ±0.1mm إلى ±0.5mm (حسب الحجم والشكل) |

| حالة المعالجة الحرارية | مخمرة، صلبة ومقواة، مخففة الإجهاد |

| درجات الجودة | درجة قياسية، درجة الطيران، درجة المحامل |

| التغليف | صناديق خشبية، حزم فولاذية، تغليف مخصص متاح |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing AISI M50

تكنولوجيا معالجة VIM/VAR المتقدمة

تستخدم MetalZenith تقنيات متقدمة في الصهر بالتحريض الفراغي (VIM) تليها عمليات إعادة الصهر بالقوس الفراغي (VAR) لإنتاج فولاذ AISI M50 فائق النقاء مع الحد الأدنى من الشوائب، وتجانس كيميائي متفوق، وأداء محسّن في مقاومة التعب للتطبيقات الجوية الحرجة.

أنظمة مراقبة الجودة الشاملة

يتميز مختبر مراقبة الجودة المتطور لدينا بمعدات اختبار متقدمة تشمل مطياف الانبعاث الضوئي، وآلات الاختبار العالمية، وأنظمة التحليل المعدني، مما يضمن أن كل دفعة تلبي المواصفات الصارمة للطيران مع وثائق تتبع كاملة.

معالجة مخصصة وسلسلة التوريد العالمية

تقدم MetalZenith خدمات تخصيص كاملة بما في ذلك التشكيل الدقيق، والمعالجة الحرارية في جو محكم، والتشغيل وفقًا لمواصفات العملاء. تضمن شبكتنا العالمية للتوزيع تسليم موثوق لمنتجات AISI M50 في جميع أنحاء العالم مع دعم فني شامل.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات