20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

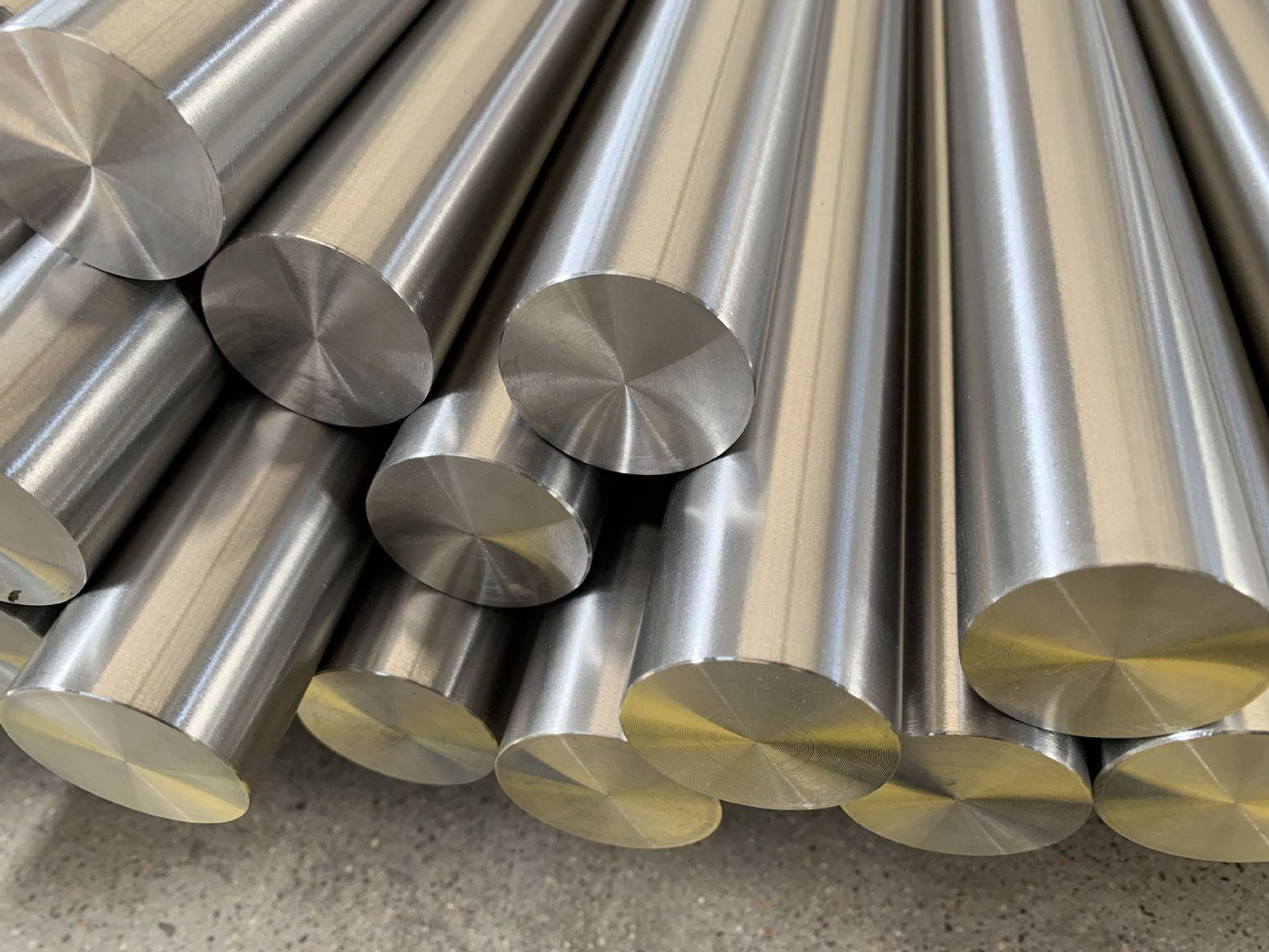

Product Overview

Metallurgical Characteristics

Maraging 350 exhibits a unique martensitic microstructure strengthened by precipitation of intermetallic compounds including Ni3Mo, Ni3Ti, and Fe2Mo during aging treatment. The low carbon content ensures excellent weldability while maintaining ultra-high strength through age hardening mechanisms. The fine martensitic matrix provides exceptional toughness and dimensional stability.

Heat Treatment Process

MetalZenith employs solution annealing at 815-845°C followed by controlled aging at 480°C for 3 hours. This precise thermal cycle ensures optimal precipitation of strengthening phases while maintaining excellent ductility and impact resistance. Our controlled atmosphere processing prevents oxidation and ensures consistent properties throughout the material cross-section.

Manufacturing Process Excellence

Our advanced vacuum induction melting process ensures exceptional cleanliness and homogeneity. Controlled forging and rolling operations maintain optimal grain structure, while our proprietary aging cycles deliver consistent ultra-high strength properties. Real-time monitoring systems ensure precise temperature control throughout all processing stages.

Specialized Quality Testing

Comprehensive testing includes TIG and MIG welding performance evaluation, bend testing for forming behavior assessment, rotating beam fatigue testing to 10^7 cycles, and salt spray corrosion testing per ASTM B117. Ultrasonic inspection ensures internal soundness while hardness mapping verifies uniform age hardening response.

Structural Application Considerations

For building construction, Maraging 350 provides exceptional strength-to-weight ratios in critical load-bearing applications. Bridge engineering benefits from superior fatigue resistance and dimensional stability. Machinery manufacturing utilizes the excellent machinability and weldability for precision structural components. Vehicle manufacturing leverages the high strength for weight reduction while maintaining safety performance. General engineering applications benefit from the combination of ultra-high strength and good toughness for demanding structural requirements.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤ 0.03 |

| Nickel (Ni) | 17.0 - 19.0 |

| Cobalt (Co) | 11.5 - 12.5 |

| Molybdenum (Mo) | 4.6 - 5.2 |

| Titanium (Ti) | 1.3 - 1.8 |

| Aluminum (Al) | 0.05 - 0.15 |

| Silicon (Si) | ≤ 0.10 |

| Iron (Fe) | Balance |

⚙️ Mechanical Properties

| Property | Value |

|---|---|

| Yield Strength (MPa) | ≥ 2400 |

| Tensile Strength (MPa) | 2450 - 2650 |

| Elongation (%) | ≥ 8 |

| Impact Energy at RT (J) | ≥ 20 |

| Hardness (HRC) | 50 - 55 |

| Fatigue Strength (MPa) | ≥ 1200 |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density (g/cm3) | 8.10 |

| Melting Point (°C) | 1413 - 1440 |

| Thermal Conductivity (W/m·K) | 17.0 |

| Thermal Expansion (×10??/K) | 10.1 |

| Elastic Modulus (GPa) | 186 |

| Poisson's Ratio | 0.31 |

📏 Product Specifications

| Specification | Details |

|---|---|

| Available Forms | Plates, Bars, Forgings, Billets, Custom Shapes |

| Thickness Range | 3 - 200mm |

| Width Range | 100 - 2000mm |

| Length Range | 500 - 6000mm |

| Standards Compliance | ASTM A538, AMS 6514, MIL-S-46850 |

| Heat Treatment Condition | Solution Annealed + Aged |

| Surface Finish | Hot Rolled, Cold Finished, Machined |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing Maraging 350 Steel

Precision Vacuum Melting & Age Hardening

MetalZenith utilizes advanced vacuum induction melting followed by controlled aging at 480°C to achieve optimal precipitation hardening. Our precise temperature control and atmosphere management ensure consistent ultra-high strength properties and exceptional dimensional stability throughout the material cross-section.

Comprehensive Structural Performance Testing

Our quality assurance includes specialized testing for structural applications: advanced welding performance evaluation, forming behavior analysis under high stress, fatigue strength testing up to 10^7 cycles, and accelerated atmospheric corrosion resistance testing to ensure long-term structural integrity.

Custom Structural Solutions & Engineering Support

MetalZenith provides tailored processing solutions including custom heat treatment cycles, precision machining to tight tolerances, and comprehensive technical support for structural design optimization. Our engineering team assists with material selection and application-specific property enhancement.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications