20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

Product Overview

Metallurgical Characteristics

JIS SM570 is a high-strength low-alloy (HSLA) structural steel featuring a fine-grained ferrite-pearlite microstructure achieved through controlled rolling and accelerated cooling processes. The steel's exceptional strength-to-weight ratio is derived from solid solution strengthening, precipitation hardening, and grain refinement mechanisms. Microalloying elements such as niobium and vanadium form fine carbides and nitrides that effectively pin grain boundaries and dislocations.

Manufacturing Process

MetalZenith produces JIS SM570 using advanced electric arc furnace steelmaking followed by ladle refining and vacuum degassing to achieve ultra-low sulfur and phosphorus contents. The steel undergoes thermomechanical controlled processing (TMCP) involving controlled rolling in the austenite recrystallization and non-recrystallization regions, followed by accelerated cooling to optimize the final microstructure and mechanical properties.

Heat Treatment Guidelines

JIS SM570 is typically supplied in the as-rolled or normalized condition. For stress relief applications, heating to 580-620°C followed by slow cooling is recommended. Welding preheat temperature should be maintained at 100-150°C for thick sections (>25mm) to prevent hydrogen-induced cracking. Post-weld heat treatment at 600-650°C may be required for critical applications to relieve residual stresses.

Weldability and Fabrication

The steel exhibits excellent weldability with carbon equivalent (Ceq) values typically below 0.44%, making it suitable for all conventional welding processes including SMAW, GMAW, FCAW, and SAW. The controlled chemistry ensures minimal risk of cold cracking and good notch toughness in the heat-affected zone. Proper welding procedures and consumables selection are essential for maintaining joint integrity and mechanical properties.

Quality Standards and Compliance

MetalZenith's JIS SM570 steel fully complies with JIS G 3106 specifications and is manufactured under ISO 9001:2015 quality management systems. Each production lot undergoes comprehensive testing including chemical analysis by optical emission spectroscopy, mechanical property verification, ultrasonic testing for internal soundness, and dimensional inspection. Mill test certificates provide complete traceability and compliance documentation for all delivered materials.

🧪 Chemical Composition

| Element | Composition (%) | Purpose |

|---|---|---|

| Carbon (C) | ≤ 0.18 | Strength and hardness |

| Manganese (Mn) | 1.00 - 1.60 | Deoxidation and strength |

| Silicon (Si) | 0.15 - 0.55 | Deoxidation and strength |

| Phosphorus (P) | ≤ 0.030 | Controlled impurity |

| Sulfur (S) | ≤ 0.030 | Controlled impurity |

| Chromium (Cr) | ≤ 0.30 | Hardenability |

| Nickel (Ni) | ≤ 0.30 | Toughness improvement |

| Molybdenum (Mo) | ≤ 0.10 | Strength enhancement |

| Copper (Cu) | ≤ 0.30 | Corrosion resistance |

| Aluminum (Al) | ≥ 0.015 | Grain refinement |

| Niobium (Nb) | ≤ 0.060 | Precipitation strengthening |

| Vanadium (V) | ≤ 0.15 | Grain refinement |

⚙️ Mechanical Properties

| Property | Value | Test Standard |

|---|---|---|

| Yield Strength (0.2% offset) | ≥ 460 MPa | JIS Z 2241 |

| Tensile Strength | 570 - 720 MPa | JIS Z 2241 |

| Elongation (50mm gauge) | ≥ 17% | JIS Z 2241 |

| Elongation (200mm gauge) | ≥ 21% | JIS Z 2241 |

| Brinell Hardness (HB) | 170 - 230 | JIS Z 2243 |

| Charpy V-notch Impact (0°C) | ≥ 27 J | JIS Z 2242 |

| Charpy V-notch Impact (-20°C) | ≥ 27 J | JIS Z 2242 |

| Young's Modulus | 210 GPa | JIS Z 2280 |

| Poisson's Ratio | 0.30 | JIS Z 2280 |

| Fatigue Limit (107 cycles) | 285 MPa | JIS Z 2273 |

| Reduction of Area | ≥ 50% | JIS Z 2241 |

| Bend Test (180°) | 3t radius | JIS Z 2248 |

🔬 Physical Properties

| Property | Value | Temperature/Conditions |

|---|---|---|

| Density | 7.85 g/cm³ | 20°C |

| Melting Point | 1510°C | Solidus temperature |

| Thermal Conductivity | 54 W/m·K | 20°C |

| Thermal Expansion Coefficient | 12×10-6/K | 20-100°C |

| Specific Heat Capacity | 500 J/kg·K | 20°C |

| Electrical Resistivity | 0.16 µΩ·m | 20°C |

| Magnetic Permeability | Ferromagnetic | Room temperature |

| Curie Temperature | 770°C | Magnetic transition |

| Thermal Diffusivity | 13.7×10-6 m²/s | 20°C |

| Emissivity | 0.85 | Oxidized surface |

| Sound Velocity (longitudinal) | 5900 m/s | 20°C |

| Bulk Modulus | 175 GPa | Room temperature |

📏 Product Specifications

| Specification | Available Options | Standards |

|---|---|---|

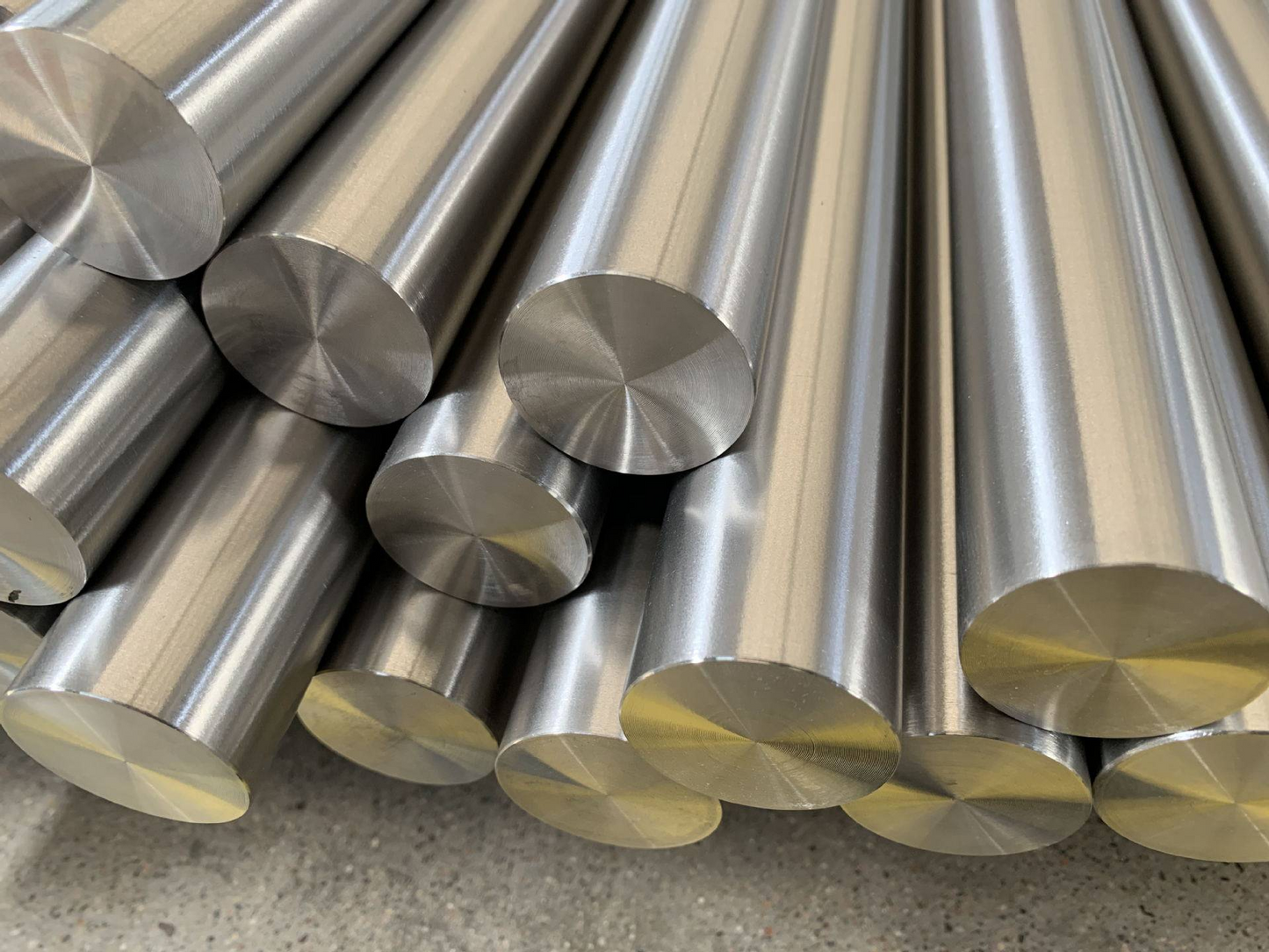

| Product Forms | Plates, Sheets, Bars, Beams, Channels, Angles | JIS G 3106 |

| Plate Thickness | 6mm - 200mm | JIS G 3106 |

| Sheet Thickness | 1.5mm - 6mm | JIS G 3106 |

| Width Range | 1000mm - 4000mm | Mill standard |

| Length Range | 2000mm - 18000mm | Mill standard |

| Bar Diameter | 10mm - 300mm | JIS G 4051 |

| Surface Finish | Hot Rolled, Normalized, Shot Blasted, Pickled | JIS G 0601 |

| Dimensional Tolerance | ±0.5mm (thickness), ±5mm (width/length) | JIS G 3193 |

| Flatness Tolerance | ≤ 5mm/m | JIS G 3193 |

| Edge Condition | Mill Edge, Sheared Edge, Flame Cut | Customer specification |

| Heat Treatment | As Rolled, Normalized, TMCP | JIS G 3106 |

| Testing Requirements | Mill Test Certificate, Third Party Inspection | JIS G 0404 |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing JIS SM570

Advanced Thermomechanical Processing

MetalZenith employs cutting-edge controlled rolling and accelerated cooling technologies to achieve optimal grain refinement and precipitation strengthening in JIS SM570 steel, resulting in superior strength and toughness properties that exceed standard specifications.

Comprehensive Quality Control System

Our integrated quality management system features real-time chemical composition monitoring, automated dimensional inspection, and 100% ultrasonic testing. Every steel product is traceable through our digital quality tracking system with complete mill test certificates.

Flexible Customization & Global Supply

MetalZenith offers extensive customization options including non-standard dimensions, special surface treatments, and application-specific heat treatments. Our global distribution network ensures reliable delivery worldwide with comprehensive technical support and engineering consultation services.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications