20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

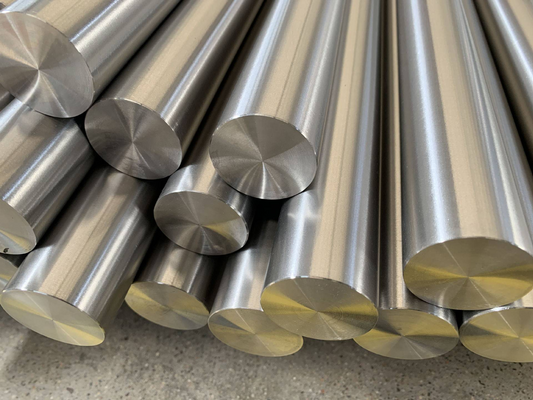

Product Overview

Metallurgical Characteristics

GB Q460 is a high-strength low-alloy (HSLA) structural steel featuring a fine-grained ferrite-pearlite microstructure achieved through controlled rolling and microalloying additions. The steel incorporates niobium, vanadium, and titanium for grain refinement and precipitation strengthening, resulting in excellent strength-toughness balance and superior weldability compared to conventional carbon steels.

Manufacturing Process at MetalZenith

MetalZenith employs advanced electric arc furnace (EAF) steelmaking followed by ladle refining to achieve precise chemical composition control. The steel undergoes controlled rolling in our state-of-the-art rolling mills with computerized process control, ensuring optimal austenite conditioning and transformation kinetics. Accelerated cooling techniques are applied to achieve the desired mechanical properties while maintaining excellent toughness at low temperatures.

Heat Treatment Procedures

GB Q460 is typically supplied in the as-rolled condition, utilizing thermomechanical controlled processing (TMCP) to achieve specified properties. When normalizing is required, the steel is heated to 850-950°C followed by air cooling. Stress relief annealing at 580-650°C may be performed after welding or forming operations. MetalZenith's heat treatment facilities feature precise temperature control and uniform heating to ensure consistent results.

Welding Characteristics

The steel exhibits excellent weldability with carbon equivalent (CE) values typically below 0.45%, minimizing the risk of cold cracking. Preheating is generally not required for sections up to 25mm thickness. Post-weld heat treatment may be beneficial for thick sections or critical applications. Compatible welding consumables include low-hydrogen electrodes and matching strength filler metals.

Quality Standards & Compliance

MetalZenith's GB Q460 production strictly adheres to GB/T 1591 specifications with additional compliance to international standards including EN 10025-4 (S460 equivalent) and ASTM A572. Our quality management system encompasses incoming raw material inspection, in-process monitoring, final product testing, and comprehensive documentation. Third-party inspection services are available upon request.

Technical Support & Engineering Services

MetalZenith provides comprehensive technical support including material selection guidance, welding procedure development, heat treatment recommendations, and application-specific property optimization. Our metallurgical engineering team offers consultation on design considerations, fabrication techniques, and performance optimization to ensure successful project outcomes.

🧪 Chemical Composition

| Element | Content (%) | Grade Q460C | Grade Q460D |

|---|---|---|---|

| Carbon (C) | ≤ 0.20 | ≤ 0.18 | ≤ 0.18 |

| Manganese (Mn) | 1.00-1.70 | 1.00-1.70 | 1.00-1.70 |

| Silicon (Si) | 0.15-0.55 | 0.15-0.55 | 0.15-0.55 |

| Phosphorus (P) | ≤ 0.030 | ≤ 0.025 | ≤ 0.025 |

| Sulfur (S) | ≤ 0.030 | ≤ 0.015 | ≤ 0.010 |

| Chromium (Cr) | ≤ 0.80 | ≤ 0.80 | ≤ 0.80 |

| Nickel (Ni) | ≤ 0.80 | ≤ 0.80 | ≤ 0.80 |

| Molybdenum (Mo) | ≤ 0.30 | ≤ 0.30 | ≤ 0.30 |

| Vanadium (V) | 0.02-0.15 | 0.02-0.15 | 0.02-0.15 |

| Niobium (Nb) | 0.015-0.060 | 0.015-0.060 | 0.015-0.060 |

| Titanium (Ti) | 0.02-0.20 | 0.02-0.20 | 0.02-0.20 |

| Aluminum (Al) | ≥ 0.015 | ≥ 0.015 | ≥ 0.015 |

⚙️ Mechanical Properties

| Property | Thickness (mm) | Value | Test Standard |

|---|---|---|---|

| Yield Strength (MPa) | ≤ 16 | ≥ 460 | GB/T 228.1 |

| Yield Strength (MPa) | 16-40 | ≥ 440 | GB/T 228.1 |

| Yield Strength (MPa) | 40-63 | ≥ 420 | GB/T 228.1 |

| Tensile Strength (MPa) | ≤ 63 | 570-720 | GB/T 228.1 |

| Elongation (%) | ≤ 63 | ≥ 17 | GB/T 228.1 |

| Impact Energy (J) | 20°C | ≥ 34 | GB/T 229 |

| Impact Energy (J) | 0°C | ≥ 34 | GB/T 229 |

| Impact Energy (J) | -20°C | ≥ 34 | GB/T 229 |

| Brinell Hardness (HB) | All | 170-230 | GB/T 231.1 |

| Fatigue Limit (MPa) | All | 240-280 | GB/T 4337 |

| Modulus of Elasticity (GPa) | All | 206 | GB/T 22315 |

| Poisson's Ratio | All | 0.26-0.30 | GB/T 22315 |

🔬 Physical Properties

| Property | Value | Temperature | Units |

|---|---|---|---|

| Density | 7.85 | 20°C | g/cm³ |

| Melting Point | 1510-1540 | - | °C |

| Thermal Conductivity | 54 | 20°C | W/m·K |

| Thermal Conductivity | 46 | 100°C | W/m·K |

| Thermal Expansion Coefficient | 12.5×10-6 | 20-100°C | /K |

| Thermal Expansion Coefficient | 13.8×10-6 | 20-200°C | /K |

| Specific Heat Capacity | 500 | 20°C | J/kg·K |

| Electrical Resistivity | 0.16 | 20°C | µΩ·m |

| Magnetic Permeability | Ferromagnetic | 20°C | - |

| Curie Temperature | 770 | - | °C |

| Thermal Diffusivity | 13.8×10-6 | 20°C | m²/s |

| Emissivity | 0.85-0.95 | 600°C | - |

📏 Product Specifications

| Specification | Available Options | Size Range | Standards |

|---|---|---|---|

| Plates | Hot Rolled, Normalized | 6-100mm thickness | GB/T 1591, GB/T 3274 |

| Sheets | Hot Rolled, Cold Rolled | 1.5-6mm thickness | GB/T 1591, GB/T 708 |

| Bars | Round, Square, Flat | 10-300mm diameter | GB/T 1591, GB/T 702 |

| Structural Sections | H-beam, I-beam, Channel | Per GB/T 11263 | GB/T 1591, GB/T 11263 |

| Tubes | Seamless, Welded | 20-600mm OD | GB/T 8162, GB/T 8163 |

| Surface Finish | Black, Pickled, Shot Blasted | Ra 1.6-12.5 µm | GB/T 1031 |

| Dimensional Tolerance | Standard, Precision | ±0.1-±3.0mm | GB/T 709, GB/T 708 |

| Length | Fixed, Random | 3-12m standard | Customer specification |

| Edge Condition | Mill Edge, Cut Edge | As per requirement | GB/T 709 |

| Heat Treatment | As Rolled, Normalized | 850-950°C | GB/T 1591 |

| Testing | Mill Test Certificate | 3.1, 3.2 per EN 10204 | EN 10204, GB/T 1591 |

| Packaging | Bundle, Crate, Container | Export standard | Customer requirement |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing GB Q460

Advanced Thermomechanical Processing

MetalZenith utilizes cutting-edge controlled rolling technology and precise temperature control systems to achieve optimal grain refinement and mechanical properties in GB Q460 steel, ensuring consistent quality and superior performance characteristics.

Comprehensive Quality Control Systems

Our state-of-the-art testing laboratory features advanced spectrometers, universal testing machines, and ultrasonic inspection equipment, enabling 100% quality verification and compliance with GB/T 1591 standards for every production batch.

Global Supply Chain & Customization

MetalZenith offers flexible customization options including specific dimensions, surface treatments, and mechanical property requirements, backed by our efficient global logistics network ensuring timely delivery worldwide.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications