20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

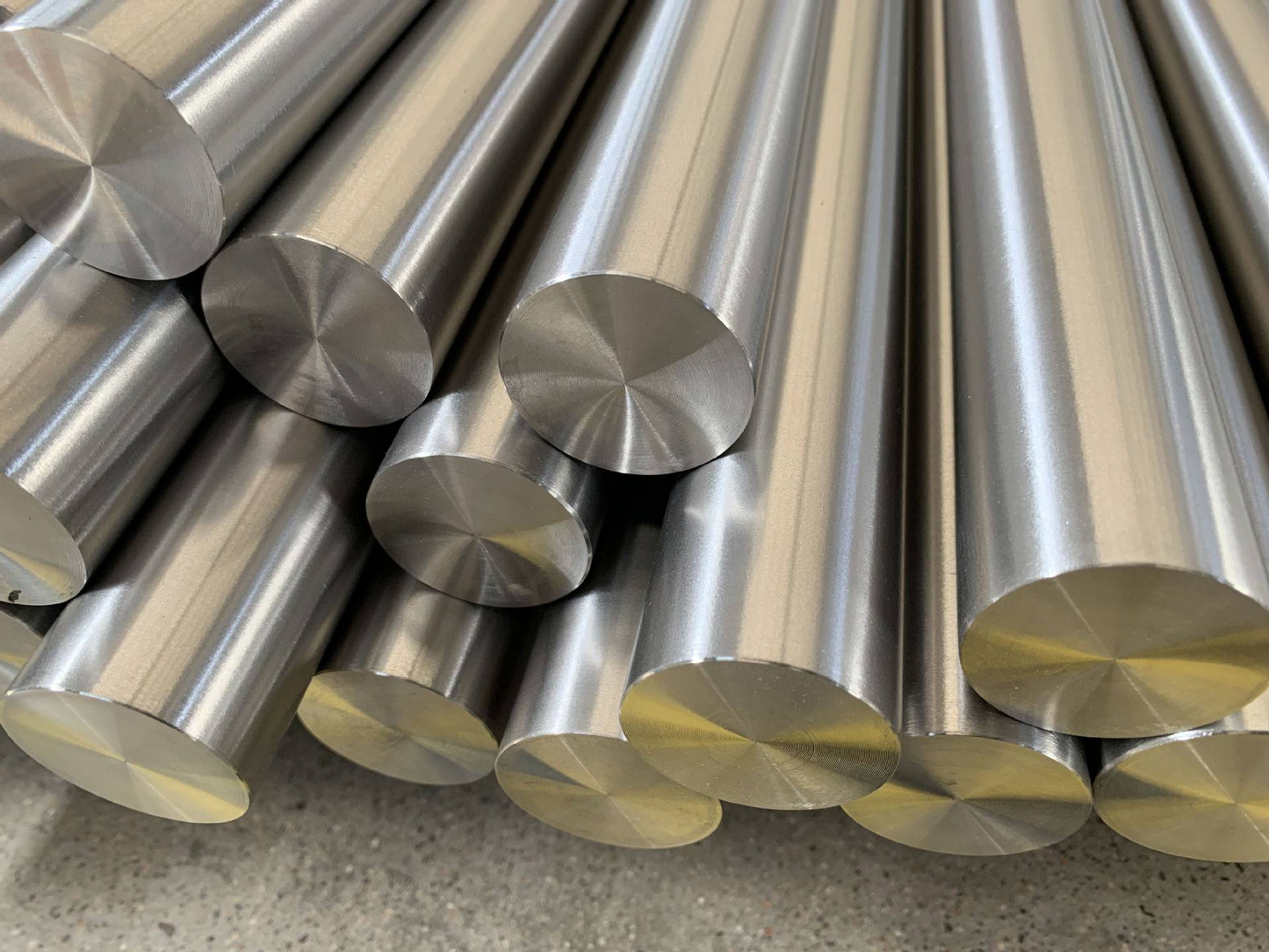

Product Overview

Metallurgical Characteristics

EN 16MnCr5 is a low-alloy case hardening steel with excellent hardenability due to its balanced chromium and manganese content. The steel exhibits a fine-grained ferritic-pearlitic microstructure in the normalized condition, which transforms to martensite in the case layer during carburizing and quenching processes. The chromium content enhances hardenability and provides moderate corrosion resistance, while manganese improves strength and toughness.

Heat Treatment Process

MetalZenith's heat treatment process for EN 16MnCr5 involves carburizing at 900-950°C for 4-12 hours depending on case depth requirements, followed by direct quenching in oil or controlled atmosphere quenching. Tempering is performed at 150-200°C to achieve optimal case hardness of 58-62 HRC while maintaining core toughness. Our controlled atmosphere furnaces ensure uniform carbon penetration and minimal distortion.

Manufacturing Process

MetalZenith produces EN 16MnCr5 using electric arc furnace melting followed by ladle refining and vacuum degassing to achieve superior steel cleanliness. The steel is cast into continuous casting billets and hot rolled to final dimensions with controlled cooling to optimize microstructure. Our advanced rolling mills ensure precise dimensional control and excellent surface quality.

Quality Standards & Testing

All EN 16MnCr5 products undergo comprehensive quality testing including chemical analysis by optical emission spectrometry, mechanical property verification through tensile and impact testing, and metallographic examination for grain size and inclusion rating. MetalZenith maintains full traceability from raw materials to finished products, with test certificates provided for every shipment in accordance with EN 10204 Type 3.1 requirements.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.14 - 0.19 |

| Manganese (Mn) | 1.00 - 1.30 |

| Silicon (Si) | 0.15 - 0.40 |

| Phosphorus (P) | ≤ 0.025 |

| Sulfur (S) | ≤ 0.035 |

| Chromium (Cr) | 0.80 - 1.10 |

| Nickel (Ni) | ≤ 0.30 |

| Molybdenum (Mo) | ≤ 0.08 |

| Aluminum (Al) | 0.020 - 0.050 |

| Copper (Cu) | ≤ 0.30 |

⚙️ Mechanical Properties

| Property | Value | Condition |

|---|---|---|

| Tensile Strength | 780 - 980 MPa | Normalized |

| Yield Strength (0.2%) | ≥ 490 MPa | Normalized |

| Elongation | ≥ 14% | Normalized |

| Reduction of Area | ≥ 45% | Normalized |

| Hardness (Brinell) | 230 - 280 HB | Normalized |

| Impact Energy (Charpy V) | ≥ 35 J | 20°C |

| Case Hardness | 58 - 62 HRC | Case Hardened |

| Core Hardness | 25 - 40 HRC | Case Hardened |

| Fatigue Limit | 380 - 420 MPa | 10&sup7; cycles |

🔬 Physical Properties

| Property | Value | Temperature |

|---|---|---|

| Density | 7.85 g/cm³ | 20°C |

| Melting Point | 1480 - 1520°C | - |

| Thermal Conductivity | 42 W/m·K | 20°C |

| Thermal Expansion Coefficient | 11.5×10-6/K | 20-100°C |

| Specific Heat Capacity | 460 J/kg·K | 20°C |

| Electrical Resistivity | 0.22 µΩ·m | 20°C |

| Young's Modulus | 210 GPa | 20°C |

| Poisson's Ratio | 0.27 - 0.30 | 20°C |

| Magnetic Permeability | Ferromagnetic | 20°C |

📏 Product Specifications

| Specification | Available Options | Standards |

|---|---|---|

| Product Forms | Round bars, square bars, flat bars, plates, sheets, forgings | EN 10083-3 |

| Round Bar Diameter | 10 - 300 mm | EN 10060 |

| Square Bar Size | 10×10 - 150×150 mm | EN 10059 |

| Flat Bar Size | 10-200 mm (thickness) × 20-500 mm (width) | EN 10058 |

| Plate Thickness | 8 - 100 mm | EN 10025 |

| Length | 3000 - 12000 mm (standard), custom lengths available | Customer specification |

| Surface Finish | Hot rolled, cold drawn, peeled, ground, machined | EN 10221 |

| Dimensional Tolerance | h9, h10, h11 (bars), ±0.1-0.5 mm (plates) | ISO 286 |

| Heat Treatment Condition | Normalized, annealed, case hardened, custom heat treatment | EN 10083-3 |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing EN 16MnCr5

Advanced Vacuum Degassing Technology

MetalZenith utilizes cutting-edge vacuum degassing and ladle refining systems to achieve ultra-low inclusion content and superior steel cleanliness, resulting in enhanced fatigue resistance and improved machinability for EN 16MnCr5 production.

Comprehensive Heat Treatment Capabilities

Our state-of-the-art heat treatment facilities feature precise temperature control and atmosphere management, enabling optimized case hardening processes that deliver consistent surface hardness of 58-62 HRC while maintaining core toughness.

Flexible Customization & Global Supply

MetalZenith offers extensive customization options including specific chemical compositions, dimensional tolerances, and surface finishes. Our global distribution network ensures reliable supply chain management with just-in-time delivery capabilities worldwide.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications