20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

Product Overview

Metallurgical Characteristics

ASTM A633 Grade E is a normalized high-strength low-alloy steel featuring a fine-grained ferrite-pearlite microstructure. The controlled addition of chromium, nickel, molybdenum, and copper provides enhanced strength and atmospheric corrosion resistance. Microalloying elements including vanadium and niobium contribute to grain refinement and precipitation strengthening mechanisms.

Heat Treatment Process

MetalZenith's normalization process involves heating the steel to 900-950°C, followed by controlled air cooling to achieve optimal mechanical properties. This heat treatment refines the grain structure, improves toughness, and ensures uniform properties throughout the cross-section. Optional stress relief treatment at 580-650°C may be applied for dimensional stability in machined components.

Manufacturing Process

Our production process begins with electric arc furnace steelmaking using premium scrap and alloy additions. Secondary refining through ladle metallurgy ensures precise chemistry control and inclusion modification. Continuous casting produces high-quality billets that undergo controlled rolling with specific temperature and reduction schedules to achieve the required mechanical properties.

Quality Standards & Testing

All ASTM A633 Grade E products undergo comprehensive testing including chemical analysis by optical emission spectroscopy, tensile testing per ASTM A370, Charpy V-notch impact testing at -29°C, and ultrasonic inspection per ASTM A578. Dimensional verification, surface quality assessment, and metallographic examination ensure compliance with specification requirements. Products are supplied with certified mill test certificates and optional third-party inspection reports.

Weldability & Fabrication

ASTM A633 Grade E exhibits excellent weldability with proper preheating and post-weld heat treatment procedures. The carbon equivalent (CE) is controlled to ensure good weldability using conventional welding processes including SMAW, GMAW, and SAW. Recommended preheat temperature is 150-200°C for sections over 25mm thickness, with interpass temperature not exceeding 250°C.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤ 0.26 |

| Manganese (Mn) | 0.85 - 1.35 |

| Silicon (Si) | 0.15 - 0.50 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.035 |

| Chromium (Cr) | 0.40 - 0.65 |

| Nickel (Ni) | 0.25 - 0.50 |

| Molybdenum (Mo) | 0.15 - 0.25 |

| Copper (Cu) | 0.20 - 0.40 |

| Vanadium (V) | 0.02 - 0.10 |

| Niobium (Nb) | 0.005 - 0.05 |

| Aluminum (Al) | 0.015 - 0.065 |

⚙️ Mechanical Properties

| Property | Value |

|---|---|

| Yield Strength (Min) | 345 MPa (50 ksi) |

| Tensile Strength | 450-590 MPa (65-85 ksi) |

| Elongation (Min) | 21% (in 2 inches) |

| Charpy V-Notch Impact (-29°C) | 27 J (20 ft-lbs) Min |

| Brinell Hardness | 137-174 HB |

| Young's Modulus | 200 GPa (29,000 ksi) |

| Shear Modulus | 80 GPa (11,600 ksi) |

| Poisson's Ratio | 0.27-0.30 |

| Fatigue Limit (10&sup7; cycles) | 240 MPa (35 ksi) |

| Reduction of Area (Min) | 50% |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density | 7.85 g/cm³ |

| Melting Point | 1425-1540°C |

| Thermal Conductivity (20°C) | 52 W/m·K |

| Thermal Expansion Coefficient (20-100°C) | 12.1×10-6/K |

| Specific Heat Capacity | 460 J/kg·K |

| Electrical Resistivity (20°C) | 0.18 µΩ·m |

| Magnetic Permeability | Ferromagnetic |

| Curie Temperature | 770°C |

| Thermal Diffusivity | 14.4 mm²/s |

| Emissivity (Oxidized Surface) | 0.79 |

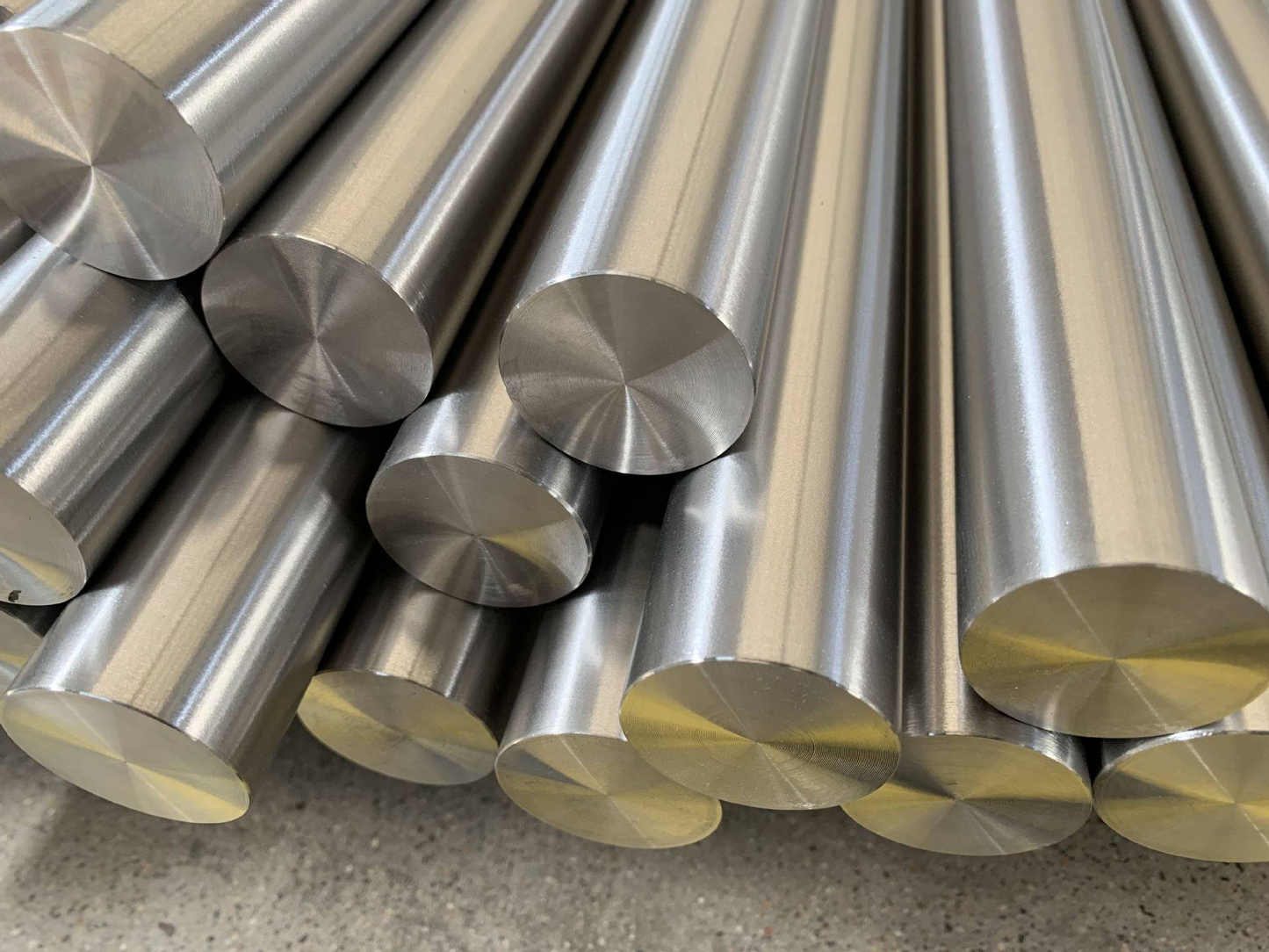

📏 Product Specifications

| Specification | Available Options |

|---|---|

| Product Forms | Plates, Sheets, Bars, Beams, Channels, Angles |

| Plate Thickness | 6-150 mm (0.25-6 inches) |

| Plate Width | 1000-4000 mm (40-160 inches) |

| Plate Length | 2000-12000 mm (80-480 inches) |

| Bar Diameter | 10-300 mm (0.4-12 inches) |

| Surface Finish | Hot Rolled, Normalized, Shot Blasted, Pickled |

| Edge Condition | Mill Edge, Sheared, Flame Cut, Machined |

| Dimensional Tolerance | ASTM A6/A6M Standard |

| Standards Compliance | ASTM A633, EN 10025-6, JIS G3106 |

| Heat Treatment | Normalized (Standard), Stress Relieved (Optional) |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing ASTM A633 Grade E

Advanced Controlled Rolling Technology

MetalZenith employs sophisticated controlled rolling and normalization processes with precise temperature monitoring to achieve optimal grain refinement and mechanical properties. Our advanced furnace technology ensures uniform heating and controlled cooling rates for consistent microstructure development.

Comprehensive Quality Control Systems

Our state-of-the-art testing laboratory features advanced spectrometers, universal testing machines, and impact testing equipment. Every production batch undergoes rigorous chemical analysis, mechanical testing, and ultrasonic inspection to guarantee compliance with ASTM A633 Grade E specifications.

Custom Processing & Global Supply Chain

MetalZenith offers extensive customization capabilities including precision cutting, machining, and surface treatment services. Our global distribution network ensures reliable delivery worldwide, with flexible order quantities from prototype to large-scale production requirements.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications