20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

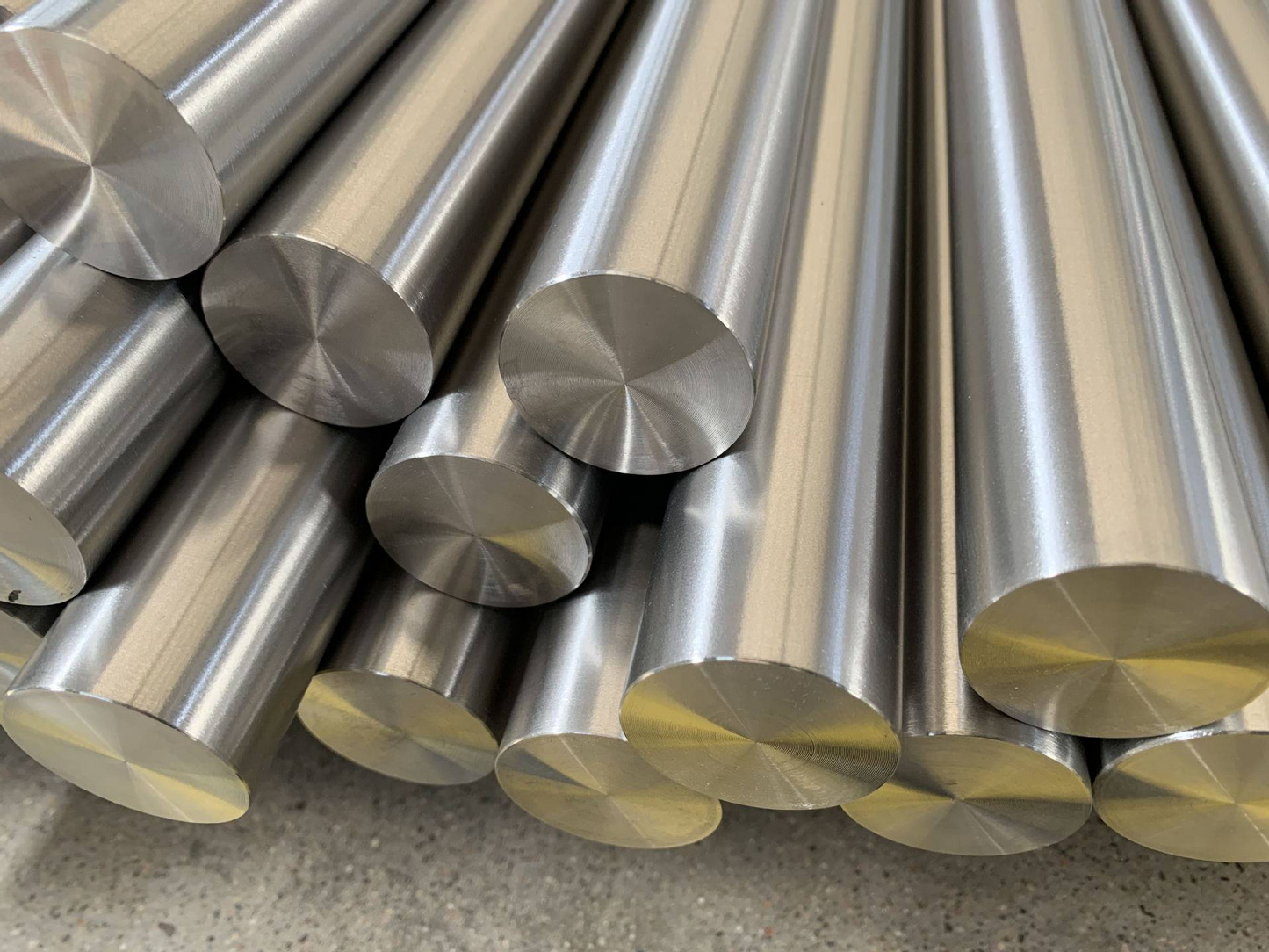

Product Overview

Metallurgical Characteristics

AISI P20 is a low-alloy tool steel with a tempered martensitic microstructure in the pre-hardened condition. The controlled addition of chromium, nickel, and molybdenum provides excellent through-hardening capability and dimensional stability. The fine carbide distribution ensures superior machinability while maintaining good wear resistance and toughness.

Heat Treatment Process

MetalZenith's proprietary heat treatment process involves austenitizing at 845-870°C, followed by controlled quenching and tempering at 540-650°C to achieve the desired hardness range of 28-32 HRC. Our computer-controlled furnaces with protective atmosphere ensure uniform heating and prevent decarburization, resulting in consistent mechanical properties throughout the cross-section.

Manufacturing Excellence

Our integrated manufacturing process begins with vacuum induction melting using premium raw materials, followed by electroslag remelting for enhanced cleanliness. Hot forging and controlled cooling optimize the grain structure, while precision machining and surface treatments meet the most demanding specifications. Advanced ultrasonic testing ensures internal soundness and reliability.

Quality Standards & Certifications

MetalZenith maintains strict adherence to international standards including ASTM A681, DIN 1.2311, and JIS SKT4. Our quality management system is certified to ISO 9001:2015, with full traceability from raw material to finished product. Comprehensive testing includes chemical analysis, mechanical property verification, hardness mapping, and dimensional inspection using coordinate measuring machines.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.28 - 0.40 |

| Manganese (Mn) | 0.60 - 1.00 |

| Silicon (Si) | 0.20 - 0.80 |

| Phosphorus (P) | ≤ 0.030 |

| Sulfur (S) | ≤ 0.030 |

| Chromium (Cr) | 1.40 - 2.00 |

| Nickel (Ni) | 0.30 - 1.00 |

| Molybdenum (Mo) | 0.15 - 0.40 |

| Aluminum (Al) | 0.020 - 0.050 |

| Copper (Cu) | ≤ 0.25 |

⚙️ Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 965 - 1100 MPa |

| Yield Strength (0.2% offset) | 795 - 930 MPa |

| Elongation | 12 - 18% |

| Reduction of Area | 40 - 55% |

| Hardness (Pre-hardened) | 28 - 32 HRC |

| Impact Energy (Charpy V-notch) | 54 - 75 J |

| Fatigue Limit (10&sup7; cycles) | 450 - 520 MPa |

| Young's Modulus | 210 GPa |

| Poisson's Ratio | 0.27 - 0.30 |

| Shear Modulus | 81 GPa |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density | 7.85 g/cm³ |

| Melting Point | 1420 - 1460°C |

| Thermal Conductivity (20°C) | 42 W/m·K |

| Thermal Expansion Coefficient (20-100°C) | 11.5×10-6/K |

| Thermal Expansion Coefficient (20-200°C) | 12.1×10-6/K |

| Specific Heat Capacity | 460 J/kg·K |

| Electrical Resistivity (20°C) | 0.25 µΩ·m |

| Magnetic Permeability | Ferromagnetic |

| Thermal Diffusivity | 11.6 mm²/s |

| Curie Temperature | 770°C |

📏 Product Specifications

| Specification | Available Options |

|---|---|

| Product Forms | Round bars, flat bars, plates, blocks, forged shapes |

| Round Bar Diameter | 10 - 500 mm |

| Flat Bar Thickness | 10 - 200 mm |

| Plate Thickness | 20 - 300 mm |

| Maximum Length | 6000 mm |

| Standards Compliance | ASTM A681, DIN 1.2311, JIS SKT4, GB 3Cr2Mo |

| Surface Finish | Hot rolled, cold drawn, turned, ground, polished |

| Dimensional Tolerance | h9 to h11 (standard), h7 to h8 (precision) |

| Straightness | ≤ 1.0 mm/m |

| Surface Quality | Ra 1.6 - 6.3 µm (as specified) |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing AISI P20

Advanced Vacuum Melting Technology

MetalZenith employs state-of-the-art vacuum induction melting (VIM) and electroslag remelting (ESR) processes to produce ultra-clean AISI P20 with minimal inclusions and superior metallurgical quality, ensuring consistent performance and extended tool life.

Precision Heat Treatment Control

Our computer-controlled heat treatment facilities with multi-zone temperature monitoring ensure uniform hardness distribution and optimal microstructure throughout the material, delivering consistent 28-32 HRC hardness with minimal variation.

Complete Supply Chain Solutions

MetalZenith offers comprehensive customization services including precision machining, surface treatments, and just-in-time delivery. Our global logistics network ensures reliable supply with full traceability and technical support throughout the product lifecycle.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications