20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

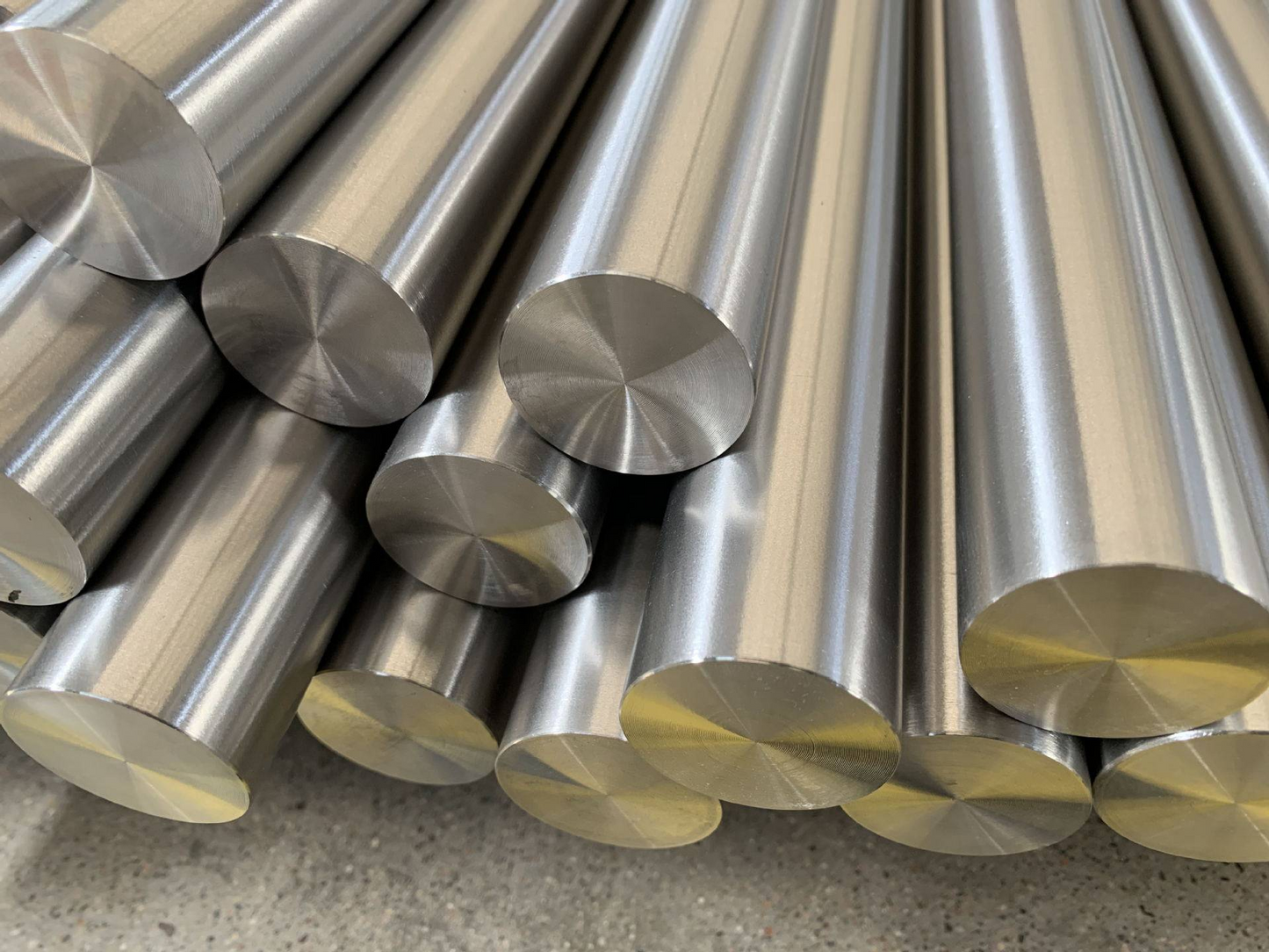

Product Overview

Metallurgical Characteristics

37MnB4 is a low-alloy boron steel designed for hot forming applications where ultra-high strength components are required. The addition of boron significantly enhances hardenability, allowing for through-hardening of thick sections with relatively simple quenching media. The steel exhibits excellent hot formability at temperatures between 900-950°C, making it ideal for press hardening operations.

Heat Treatment Process

The optimal heat treatment involves austenitizing at 900-950°C followed by rapid cooling to achieve martensitic transformation. Hot forming operations typically involve heating the blank to austenitizing temperature, forming in the die, and simultaneous quenching to achieve final properties. Tempering at 150-200°C may be applied to reduce brittleness while maintaining high strength levels.

Manufacturing Process at MetalZenith

MetalZenith produces 37MnB4 through electric arc furnace melting with precise boron addition during secondary metallurgy. The steel undergoes vacuum degassing to minimize hydrogen content and inclusion formation. Controlled rolling and cooling processes ensure optimal microstructure development and consistent mechanical properties throughout the product cross-section.

Quality Standards & Testing

All 37MnB4 products undergo comprehensive testing including chemical analysis by optical emission spectrometry, mechanical property verification through tensile and hardness testing, and microstructural examination. Hardenability testing ensures consistent performance in hot forming applications. MetalZenith maintains full traceability from raw materials through final product delivery, with certificates of compliance provided for all shipments.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.34 - 0.40 |

| Manganese (Mn) | 1.20 - 1.50 |

| Silicon (Si) | 0.15 - 0.35 |

| Phosphorus (P) | ≤ 0.025 |

| Sulfur (S) | ≤ 0.025 |

| Chromium (Cr) | 0.15 - 0.35 |

| Boron (B) | 0.0008 - 0.0050 |

| Aluminum (Al) | 0.020 - 0.060 |

| Nitrogen (N) | ≤ 0.012 |

| Titanium (Ti) | 0.020 - 0.050 |

⚙️ Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength (As-delivered) | 600 - 750 MPa |

| Yield Strength (As-delivered) | 350 - 450 MPa |

| Elongation (As-delivered) | ≥ 20% |

| Hardness (As-delivered) | 180 - 220 HBW |

| Tensile Strength (After Hot Forming) | ≥ 1500 MPa |

| Yield Strength (After Hot Forming) | ≥ 1200 MPa |

| Elongation (After Hot Forming) | ≥ 6% |

| Hardness (After Hot Forming) | 450 - 520 HV |

| Impact Energy (Charpy V-notch) | ≥ 27 J at 20°C |

| Young's Modulus | 210 GPa |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density | 7.85 g/cm³ |

| Melting Point | 1480 - 1520°C |

| Thermal Conductivity (20°C) | 42 W/m·K |

| Thermal Expansion Coefficient (20-100°C) | 11.5×10-6/K |

| Specific Heat Capacity | 460 J/kg·K |

| Electrical Resistivity (20°C) | 0.18 µΩ·m |

| Magnetic Permeability | Ferromagnetic |

| Curie Temperature | 770°C |

| Poisson's Ratio | 0.27 - 0.30 |

| Austenitizing Temperature | 900 - 950°C |

📏 Product Specifications

| Specification | Available Options |

|---|---|

| Product Forms | Hot rolled sheets, Cold rolled sheets, Coils, Blanks |

| Thickness Range | 0.8 - 6.0 mm |

| Width Range | 600 - 2000 mm |

| Length Range | 1000 - 6000 mm (sheets) |

| Coil Weight | Up to 25 tons |

| Surface Finish | Hot rolled, Pickled, Oiled, Al-Si coated |

| Thickness Tolerance | ± 0.05 mm |

| Width Tolerance | ± 2.0 mm |

| Standards Compliance | EN 10083-3, JIS G4053, ASTM A29 |

| Edge Condition | Mill edge, Trimmed edge, Slit edge |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing 37MnB4

Advanced Boron Microalloying Technology

MetalZenith employs precision boron addition techniques and controlled cooling processes to achieve optimal boron distribution and hardenability enhancement, ensuring consistent mechanical properties and superior hot forming performance across all product batches.

Comprehensive Quality Control Systems

Our state-of-the-art testing facilities include advanced spectrometers, universal testing machines, and metallographic equipment to verify chemical composition, mechanical properties, and microstructural integrity, guaranteeing compliance with international standards.

Flexible Production & Global Supply

MetalZenith offers customized dimensions, surface finishes, and delivery schedules through our integrated production facilities and global distribution network, providing just-in-time delivery and technical support for specialized applications worldwide.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications