20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

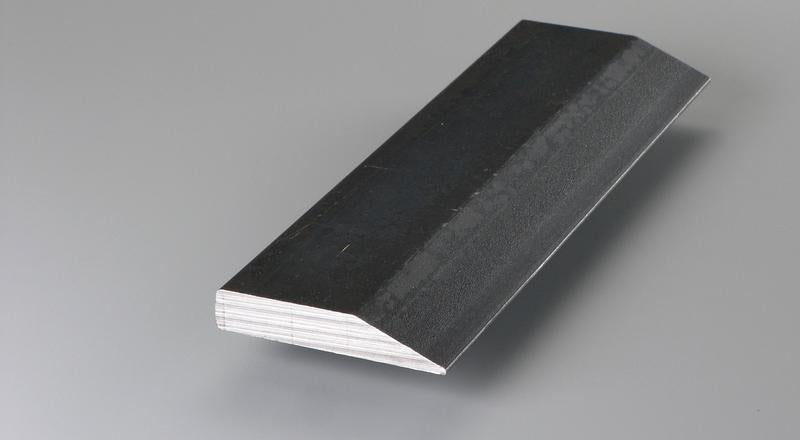

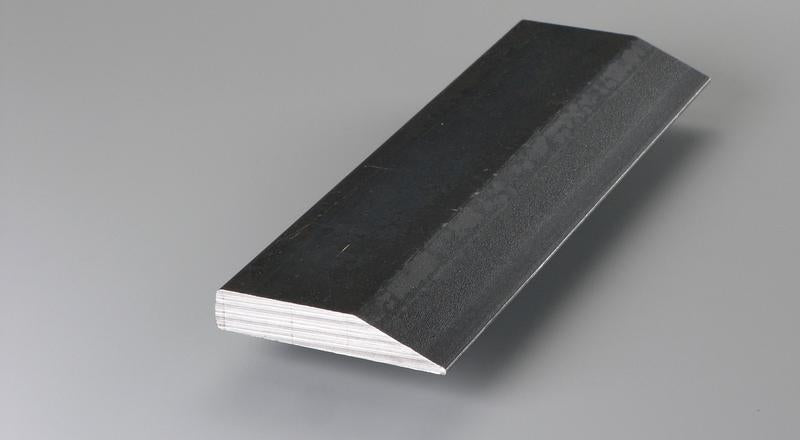

Product Overview

1055 Steel Beveled Cutting Edge is manufactured from high-carbon AISI 1055 steel, specifically designed for cutting applications requiring excellent wear resistance and edge retention. This medium-high carbon steel provides optimal hardness and toughness balance for demanding cutting operations.

Key Features:

- High carbon content for superior hardness and wear resistance

- Precision beveled edge for optimal cutting performance

- Excellent edge retention and durability

- Good machinability in annealed condition

- Heat treatable to achieve desired hardness levels

Manufacturing Process: Precision machined or ground from hot-rolled 1055 steel bar stock, with controlled heat treatment to achieve optimal mechanical properties and precise bevel geometry.

Applications: Industrial cutting blades, shear blades, agricultural cutting implements, woodworking tools, metal cutting applications, and general purpose cutting edges requiring high wear resistance.

🧪 Chemical Composition

| Element | Min % | Max % | Typical % | AISI 1055 Requirement |

|---|---|---|---|---|

| Carbon (C) | 0.50 | 0.60 | 0.55 | 0.50-0.60 |

| Manganese (Mn) | 0.60 | 0.90 | 0.75 | 0.60-0.90 |

| Phosphorus (P) | - | 0.040 | 0.025 | ≤ 0.040 |

| Sulfur (S) | - | 0.050 | 0.030 | ≤ 0.050 |

| Silicon (Si) | - | 0.40 | 0.25 | ≤ 0.40 |

| Chromium (Cr) | - | 0.30 | 0.15 | ≤ 0.30 |

| Nickel (Ni) | - | 0.30 | 0.15 | ≤ 0.30 |

| Copper (Cu) | - | 0.30 | 0.15 | ≤ 0.30 |

| Iron (Fe) | Balance | Balance | 97.8 | Balance |

⚙️ Mechanical Properties

| Property | ASTM Requirement | Typical Value | Test Method | Temperature |

|---|---|---|---|---|

| Tensile Strength | 690 MPa min | 750 MPa | ASTM A370 | Room Temp |

| Yield Strength (0.2%) | 380 MPa min | 420 MPa | ASTM A370 | Room Temp |

| Elongation | 12% min | 15% | ASTM A370 | Room Temp |

| Hardness (Brinell) | 217-269 HB | 240 HB | ASTM E10 | Room Temp |

| Hardness (Rockwell C) | 22-28 HRC | 25 HRC | ASTM E18 | Room Temp |

| Modulus of Elasticity | - | 205 GPa | ASTM E111 | Room Temp |

| Impact Energy (Charpy V) | - | 35 J | ASTM E23 | Room Temp |

🔬 Physical Properties

| Property | Value | Unit | Temperature | Test Standard |

|---|---|---|---|---|

| Density | 7.85 | g/cm3 | 20¡ãC | ASTM B311 |

| Melting Point | 1460-1520 | ¡ãC | - | DSC Analysis |

| Thermal Conductivity | 51.9 | W/m·K | 100¡ãC | ASTM E1461 |

| Specific Heat | 486 | J/kg·K | 0-100¡ãC | ASTM C351 |

| Linear Expansion | 11.7 | μm/m·K | 0-100¡ãC | ASTM E228 |

| Electrical Resistivity | 162 | nΩ·m | 20¡ãC | ASTM B193 |

| Magnetic Permeability | High | μ/μ₀ | Room Temp | ASTM A342 |

| Curie Temperature | 770 | ¡ãC | - | Magnetic |

📏 Product Specifications

| Specification | Available Range | Standard Length | Custom Available | Tolerance |

|---|---|---|---|---|

| Thickness | 3mm - 50mm | Various | Yes | ±0.5mm |

| Width | 25mm - 500mm | Various | Yes | ±1.0mm |

| Length | 100mm - 6000mm | 1000mm | Yes | +10mm/-0mm |

| Bevel Angle | 15¡ã - 45¡ã | 30¡ã | Yes | ±2¡ã |

| Edge Finish | Ground, Machined | Ground | Both | Ra ≤ 1.6μm |

| Heat Treatment | Normalized, Hardened | Normalized | Yes | ASTM A681 |

| Standards Compliance | ASTM A681, SAE 1055 | ASTM A681 | Multiple | Full compliance |

| Surface Condition | Hot Rolled, Cold Drawn | Hot Rolled | Yes | ASTM A29 |

| Test Certificate | Mill TC, EN 10204 3.1 | Mill TC | Yes | Standard |

| Packaging | Wooden Crates, Pallets | Wooden Crates | Custom | Export standard |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing 1055 เหล็กคมตัดเฉียง

High Carbon Steel Quality

Manufactured using premium 1055 carbon steel composition, delivering optimal balance between hardness and toughness. The precise carbon content ensures excellent wear resistance while maintaining structural integrity under heavy-duty applications.

Precision Beveled Edge Design

Advanced machining process creates precise beveled angles on the cutting edge, ensuring consistent sharpness and superior cutting performance. Each edge is carefully ground and inspected for optimal geometric accuracy.

Controlled Heat Treatment

Specialized heat treatment process optimizes the steel's microstructure, resulting in enhanced durability and wear resistance. The carefully controlled heating and cooling cycles ensure uniform hardness throughout the cutting edge.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications