20 Anos de Experiência | 1000+ Parceiros de Marca | Personalização Completa

Temos 20 anos de experiência na indústria, fizemos parceria com mais de 1.000 marcas e apoiamos quaisquer necessidades de personalização.

Technical Specifications

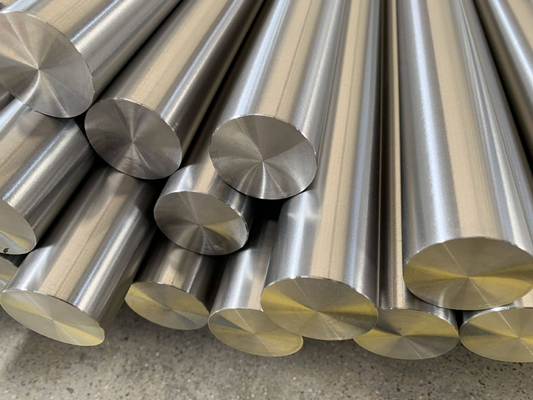

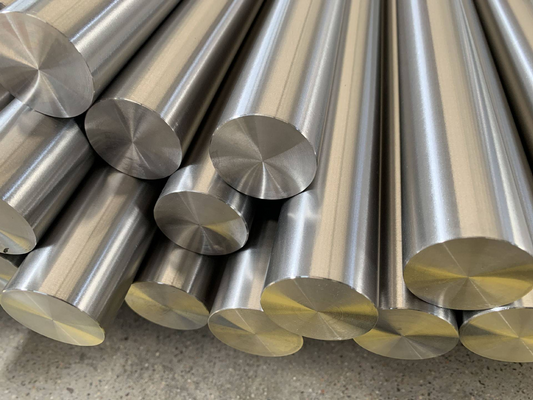

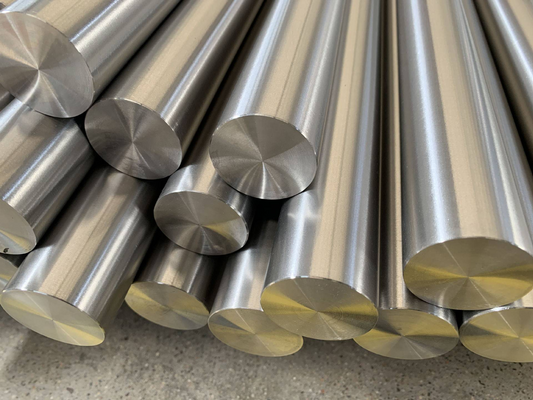

Product Overview

Características Metalúrgicas

O SAE 1524 apresenta uma microestrutura predominantemente ferrítica-perlítica com tamanho de grão fino alcançado através de processos de laminação controlados. O teor médio de carbono (0,19-0,25%) combinado com manganês (1,35-1,65%) proporciona um equilíbrio ideal entre resistência e ductilidade. A microestrutura garante excelente conformabilidade enquanto mantém resistência adequada para aplicações estruturais.

Processo de Tratamento Térmico

A MetalZenith emprega resfriamento controlado a partir da temperatura de laminação ou normalização a 870-920°C seguido de resfriamento ao ar. Para propriedades aprimoradas, pode ser aplicado alívio de tensões por recozimento a 600-650°C. Nosso controle preciso de temperatura e gerenciamento da taxa de resfriamento garantem propriedades mecânicas ideais e estabilidade dimensional.

Processo de Fabricação

Nossa produção de SAE 1524 utiliza fusão em forno de arco elétrico com refino secundário para controle preciso da química. A fundição contínua seguida de laminação controlada com temperaturas de laminação final entre 850-900°C garante microestrutura uniforme. Sistemas avançados de controle de processo monitoram temperatura, razões de redução e taxas de resfriamento durante a produção.

Teste de Qualidade Estrutural

Os testes abrangentes incluem ensaio de tração conforme ASTM A370, ensaio de impacto Charpy com entalhe em V, ensaio de dobra para avaliação de conformabilidade e ensaio de fadiga para aplicações de carga cíclica. Os testes de soldabilidade incluem levantamentos de dureza da ZTA, ensaio de dobra de juntas soldadas e testes de corrosão atmosférica conforme os padrões ASTM G50.

Engenharia de Aplicação

Para construção de edifícios, o SAE 1524 proporciona excelente soldabilidade com procedimentos padrão e requisitos de pré-aquecimento. Aplicações em pontes se beneficiam de superior resistência à fadiga e desempenho contra corrosão atmosférica. Aplicações em máquinas utilizam a relação equilibrada entre resistência e peso e usinabilidade. Componentes estruturais automotivos aproveitam a conformabilidade e as características de absorção de energia em colisões.

🧪 Chemical Composition

| Elemento | Composição (%) |

|---|---|

| Carbono (C) | 0.19 - 0.25 |

| Manganês (Mn) | 1.35 - 1.65 |

| Silício (Si) | 0.15 - 0.35 |

| Fósforo (P) | ≤ 0.030 |

| Enxofre (S) | ≤ 0.035 |

| Cromo (Cr) | ≤ 0.25 |

| Níquel (Ni) | ≤ 0.25 |

| Cobre (Cu) | ≤ 0.35 |

⚙️ Mechanical Properties

| Propriedade | Valor |

|---|---|

| Resistência ao Esforço (MPa) | 415 - 550 |

| Resistência à Tração (MPa) | 520 - 670 |

| Alongamento (%) | ≥ 18 |

| Energia de Impacto a 20°C (J) | ≥ 27 |

| Dureza (HB) | 149 - 197 |

| Resistência à Fadiga (MPa) | 260 - 335 |

🔬 Physical Properties

| Propriedade | Valor |

|---|---|

| Densidade (g/cm3) | 7.87 |

| Ponto de Fusão (°C) | 1495 - 1520 |

| Condutividade Térmica (W/m·K) | 49.8 |

| Expansão Térmica (×10??/K) | 11.7 |

| Módulo de Elasticidade (GPa) | 200 |

| Razão de Poisson | 0.27 - 0.30 |

📏 Product Specifications

| Especificação | Detalhes |

|---|---|

| Formas Disponíveis | Placas, Folhas, Barras, Vigas, Canaletas, Ângulos |

| Faixa de Espessura | 3 - 200mm |

| Faixa de Largura | 1000 - 3000mm |

| Faixa de Comprimento | 6000 - 12000mm |

| Conformidade com Normas | SAE J403, ASTM A36, AISC 360 |

| Condição de Tratamento Térmico | Laminado a Quente, Normalizado, ou Conforme Necessário |

| Acabamento de Superfície | Escama de Laminagem, Desengordurado, Jateado |

Vamos Criar Sucesso para o Seu Projeto

Equipe Profissional, Produtos Premium, Serviço Completo - O Sucesso do Seu Projeto é Nossa Missão

Our Advantages in Processing Aço SAE 1524

Tecnologia de Laminação Controlada

MetalZenith utiliza processos avançados de laminação controlada com controle preciso de temperatura e cronogramas de deformação para alcançar um refino de grão ideal no aço SAE 1524. Nosso processamento termomecânico garante uma microestrutura uniforme e propriedades mecânicas aprimoradas em toda a seção transversal do material.

Teste Estrutural Abrangente

Nosso aço SAE 1524 passa por testes extensivos, incluindo testes de impacto Charpy, testes de dobra para conformabilidade, avaliação da resistência à fadiga e avaliação da resistência à corrosão atmosférica. Também realizamos testes abrangentes de soldabilidade, incluindo análise da HAZ e verificação da resistência das juntas para garantir desempenho ideal em aplicações estruturais.

Serviços de Fabricação Personalizada

MetalZenith oferece serviços completos de processamento personalizado para o aço SAE 1524, incluindo corte de precisão, conformação, tratamento térmico e preparação de superfície. Nossa equipe técnica oferece consultoria especializada para otimização de design estrutural e desenvolvimento de procedimentos de soldagem para atender a requisitos específicos do projeto.

SEU CONFIÁVEL AÇO

PARCEIRO DE MANUFATURA

Quick Inquiry

Indústrias que Atendemos

Soluções de aço profissionais em grandes indústrias

Qualificações e Certificações