20 Anos de Experiência | 1000+ Parceiros de Marca | Personalização Completa

Temos 20 anos de experiência na indústria, fizemos parceria com mais de 1.000 marcas e apoiamos quaisquer necessidades de personalização.

Technical Specifications

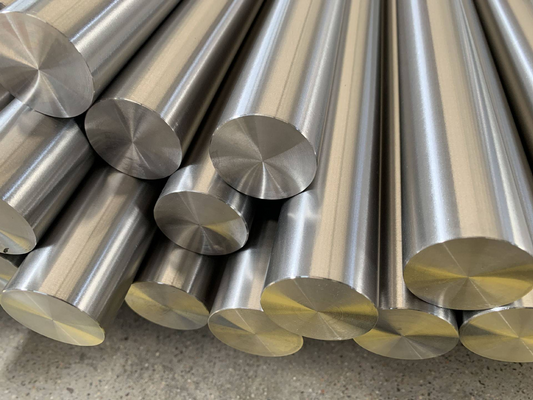

Product Overview

Características Metalúrgicas

SAE 1112 é um aço de baixo carbono, resulfurizado, com uma microestrutura predominantemente ferrítica contendo inclusões de sulfeto de manganês distribuídas uniformemente. Essas inclusões de sulfeto atuam como quebra-chips durante as operações de usinagem, proporcionando uma usinabilidade excepcional enquanto mantêm propriedades estruturais adequadas para aplicações de carga leve a média.

Processo de Tratamento Térmico

MetalZenith emprega laminação a quente controlada em temperaturas entre 1150-1200°C, seguida de resfriamento controlado para alcançar uma microestrutura ideal. Para propriedades aprimoradas, a normalização a 870-920°C pode ser aplicada. O recozimento de alívio de tensões a 550-650°C é recomendado para componentes usinados a fim de minimizar tensões residuais.

Excelência no Processo de Fabricação

Nosso avançado processo de fabricação de aço inclui controle preciso da adição de enxofre e tratamento com cálcio para otimizar a morfologia do sulfeto. O processo de laminação controlada garante uma estrutura de grão uniforme e propriedades mecânicas consistentes em toda a seção transversal, enquanto mantém as características de usinagem livre essenciais para produção em alta velocidade.

Testes de Qualidade Especializados

MetalZenith realiza testes abrangentes, incluindo avaliação de usinabilidade usando testes de corte padronizados, avaliação de soldabilidade através de testes de dobra e exame macro, testes de capacidade de conformação a frio, avaliação de resistência à fadiga sob condições de carregamento cíclico e testes de resistência à corrosão atmosférica em ambientes controlados para garantir desempenho estrutural a longo prazo.

Considerações sobre Aplicações Estruturais

Para estruturas de construção, o SAE 1112 oferece excelentes características de fabricação com boa soldabilidade usando técnicas apropriadas. Em aplicações de engenharia de pontes, o material oferece desempenho confiável para elementos estruturais secundários. Para fabricação mecânica, a usinabilidade superior permite a produção de componentes de alta precisão. Na fabricação de veículos, é adequado para suportes e peças estruturais não críticas. Para aplicações de engenharia geral, o equilíbrio entre resistência, ductilidade e usinabilidade o torna ideal para produção em alta volume de componentes estruturais.

🧪 Chemical Composition

| Elemento | Composição (%) |

|---|---|

| Carbono (C) | 0.13 máx |

| Manganês (Mn) | 0.60 - 0.90 |

| Fósforo (P) | 0.07 - 0.12 |

| Enxofre (S) | 0.16 - 0.23 |

| Silício (Si) | 0.10 máx |

| Ferro (Fe) | Equilíbrio |

⚙️ Mechanical Properties

| Propriedade | Valor |

|---|---|

| Resistência ao Esforço (MPa) | ≥ 275 |

| Resistência à Tração (MPa) | 415 - 550 |

| Alongamento (%) | ≥ 22 |

| Energia de Impacto a 20°C (J) | ≥ 27 |

| Dureza (HB) | 121 - 163 |

| Resistência à Fadiga (MPa) | 180 - 220 |

🔬 Physical Properties

| Propriedade | Valor |

|---|---|

| Densidade (g/cm3) | 7.87 |

| Ponto de Fusão (°C) | 1510 - 1540 |

| Condutividade Térmica (W/m·K) | 51.9 |

| Expansão Térmica (×10??/K) | 11.7 |

| Módulo de Elasticidade (GPa) | 200 |

| Razão de Poisson | 0.27 - 0.30 |

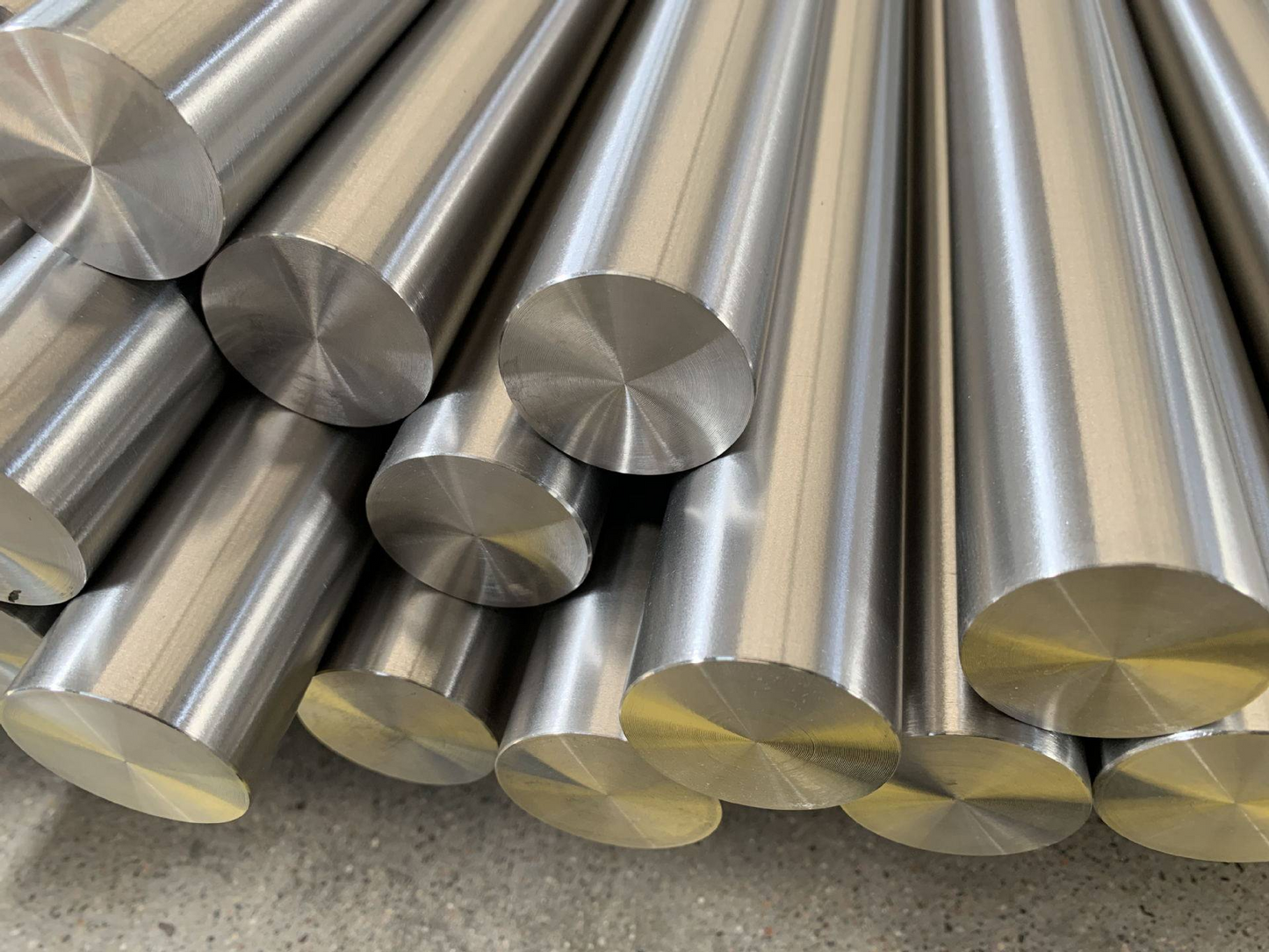

📏 Product Specifications

| Especificação | Detalhes |

|---|---|

| Formas Disponíveis | Barras, Varas, Placas, Folhas, Fios |

| Faixa de Diâmetro (Barras) | 6 - 300mm |

| Faixa de Espessura (Placas) | 3 - 50mm |

| Faixa de Largura | 500 - 2000mm |

| Faixa de Comprimento | 3000 - 12000mm |

| Conformidade com Normas | ASTM A108, SAE J403, AISI 1112 |

| Condição da Superfície | Laminado a Quente, Estirado a Frio, Usinado & Polido |

| Classificação de Usinabilidade | 100% (Padrão de Referência) |

Vamos Criar Sucesso para o Seu Projeto

Equipe Profissional, Produtos Premium, Serviço Completo - O Sucesso do Seu Projeto é Nossa Missão

Our Advantages in Processing Aço SAE 1112

Tecnologia Avançada de Laminação a Quente

MetalZenith emprega processos de laminação a quente controlados com controle de temperatura preciso e distribuição otimizada de enxofre para alcançar uma usinabilidade superior, mantendo a integridade estrutural. Nossas técnicas avançadas de laminação garantem uma estrutura de grão consistente e uma qualidade de superfície aprimorada em toda a seção transversal do material.

Teste Estrutural Abrangente

Nosso programa de garantia de qualidade inclui testes especializados para aplicações estruturais: avaliação de desempenho de soldagem, avaliação de capacidade de conformação a frio, testes de resistência à fadiga sob carregamento cíclico e testes de resistência à corrosão atmosférica para garantir durabilidade a longo prazo em ambientes estruturais.

Processamento Personalizado e Suporte Técnico

MetalZenith oferece soluções de processamento personalizadas, incluindo tratamento térmico sob medida, corte de precisão e serviços de acabamento de superfície. Nossa equipe técnica fornece suporte abrangente para otimização de design estrutural, recomendações de parâmetros de usinagem e modificações de materiais específicas para aplicações.

SEU CONFIÁVEL AÇO

PARCEIRO DE MANUFATURA

Quick Inquiry

Indústrias que Atendemos

Soluções de aço profissionais em grandes indústrias

Qualificações e Certificações