20 Anos de Experiência | 1000+ Parceiros de Marca | Personalização Completa

Temos 20 anos de experiência na indústria, fizemos parceria com mais de 1.000 marcas e apoiamos quaisquer necessidades de personalização.

Technical Specifications

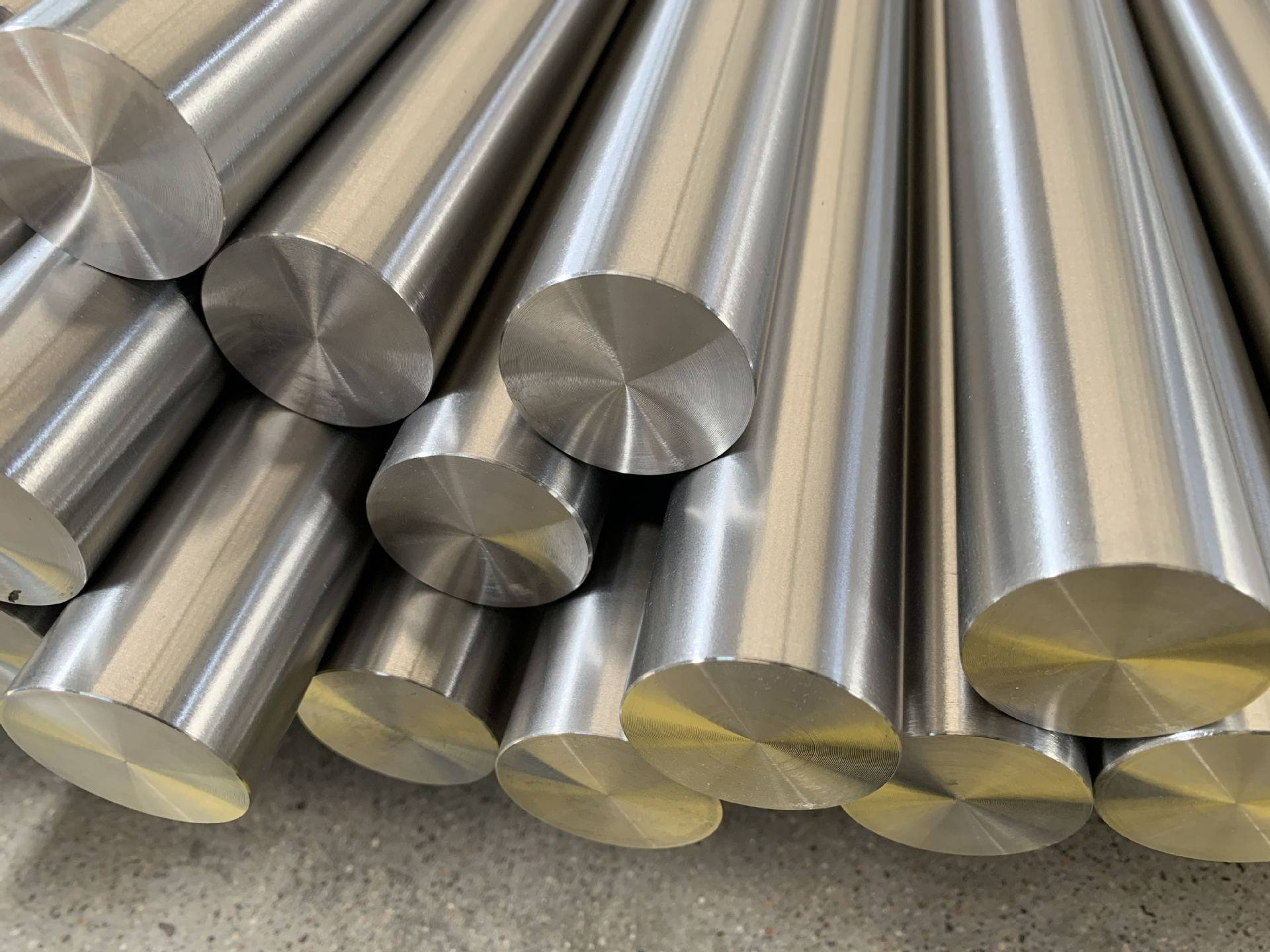

Product Overview

Características Metalúrgicas

AISI M35 é um aço de alta velocidade do tipo tungstênio-molibdênio aprimorado com adição de 5% de cobalto. O cobalto melhora significativamente a retenção de dureza a quente, resistência ao desgaste e desempenho de corte em temperaturas elevadas. O aço exibe uma estrutura complexa de carbonetos consistindo de carbonetos MC (ricos em vanádio), M6C (ricos em tungstênio-molibdênio) e M23C6 (ricos em cromo) distribuídos em uma matriz martensítica.

Processo de Tratamento Térmico

O tratamento térmico otimizado da MetalZenith inclui pré-aquecimento a 850°C, austenitização a 1210-1230°C em atmosfera protetora, seguido de resfriamento em óleo ou banho de sal. O revenimento é realizado a 540-580°C por 2-3 ciclos para alcançar a dureza desejada de 64-67 HRC. Nossas fornalhas de atmosfera controlada garantem mínima descarbonização e microestrutura ideal.

Processo de Fabricação

Nosso processo de produção começa com fusão por indução a vácuo (VIM) de matérias-primas de alta qualidade, seguido de remeltagem por eletroslag (ESR) para maior limpeza. Os lingotes passam por operações controladas de forjamento e laminação para alcançar um fluxo de grão ideal e distribuição de carbonetos. Rotas avançadas de metalurgia do pó também estão disponíveis para homogeneidade superior e estrutura de carboneto fino.

Padrões de Qualidade & Testes

Todos os produtos AISI M35 estão em conformidade com as especificações ASTM A600 e passam por controle de qualidade abrangente, incluindo análise química por espectroscopia de emissão óptica, testes de propriedades mecânicas, exame microestrutural e inspeção ultrassônica. A MetalZenith mantém a certificação ISO 9001:2015 e fornece rastreabilidade completa do material com relatórios de teste certificados para cada remessa.

🧪 Chemical Composition

| Elemento | Composição (%) |

|---|---|

| Carbono (C) | 0.90 - 0.98 |

| Manganês (Mn) | ≤ 0.40 |

| Silício (Si) | ≤ 0.45 |

| Fósforo (P) | ≤ 0.030 |

| Enxofre (S) | ≤ 0.030 |

| Cromo (Cr) | 3.75 - 4.50 |

| Molibdênio (Mo) | 4.50 - 5.50 |

| Tungstênio (W) | 5.50 - 6.75 |

| Vanádio (V) | 1.75 - 2.20 |

| Cobalto (Co) | 4.75 - 5.25 |

| Níquel (Ni) | ≤ 0.30 |

⚙️ Mechanical Properties

| Propriedade | Valor |

|---|---|

| Dureza (Recozido) | 255 - 285 HB |

| Dureza (Endurecido & Temperado) | 64 - 67 HRC |

| Dureza a Quente (600°C) | 52 - 55 HRC |

| Resistência à Tração (Recozido) | 1030 - 1200 MPa |

| Resistência de Escoamento (Recozido) | 650 - 750 MPa |

| Alongamento (Recozido) | 8 - 12% |

| Redução de Área (Recozido) | 15 - 25% |

| Energia de Impacto (Recozido) | 25 - 35 J |

| Resistência à Compressão | ≥ 3500 MPa |

| Limite de Fadiga | 450 - 550 MPa |

🔬 Physical Properties

| Propriedade | Valor |

|---|---|

| Densidade | 8.25 g/cm³ |

| Ponto de Fusão | 1480 - 1520°C |

| Condutividade Térmica (20°C) | 24 W/m·K |

| Coeficiente de Expansão Térmica (20-100°C) | 11.5×10-6/K |

| Coeficiente de Expansão Térmica (20-600°C) | 13.2×10-6/K |

| Capacidade Calorífica Específica | 460 J/kg·K |

| Resistividade Elétrica (20°C) | 0.65 µΩ·m |

| Módulo de Young | 230 GPa |

| Razão de Poisson | 0.27 - 0.30 |

| Permeabilidade Magnética | Paramagnético |

📏 Product Specifications

| Especificação | Opções Disponíveis |

|---|---|

| Formas de Produto | Barras redondas, barras planas, chapas, folhas, blocos forjados |

| Diâmetro da Barra Redonda | 6 - 300 mm |

| Dimensões da Barra Plana | 10-100 mm de espessura, até 300 mm de largura |

| Espessura da Chapa | 10 - 150 mm |

| Comprimento | Até 6000 mm (comprimentos personalizados disponíveis) |

| Normas | ASTM A600, DIN EN ISO 4957, JIS SKH59 |

| Acabamento de Superfície | Laminado a quente, trefilado a frio, usinado, retificado |

| Tolerância Dimensional | h9 a h11 (±0.1 a ±0.5 mm) |

| Condição | Recozido, endurecido e temperado |

| Embalagem | Caixas de madeira, pacotes de aço, revestimento protetor |

Vamos Criar Sucesso para o Seu Projeto

Equipe Profissional, Produtos Premium, Serviço Completo - O Sucesso do Seu Projeto é Nossa Missão

Our Advantages in Processing AISI M35

Tecnologia Avançada de Derretimento a Vácuo

MetalZenith emprega processos de fusão por indução a vácuo (VIM) e remeltagem por eletroescória (ESR) de última geração para produzir AISI M35 ultra-limpo com mínimas inclusões, distribuição superior de carbonetos e propriedades mecânicas aprimoradas para aplicações exigentes.

Tratamento Térmico de Precisão e Controle de Qualidade

Nossos protocolos de tratamento térmico proprietários e sistemas abrangentes de controle de qualidade garantem otimização consistente da microestrutura, controle preciso de dureza e precisão dimensional. Cada lote passa por testes rigorosos com certificação completa de material e rastreabilidade.

Cadeia de Suprimentos Global & Soluções Personalizadas

MetalZenith oferece opções de personalização flexíveis, incluindo dimensões especializadas, tratamentos de superfície e embalagem. Nossa rede de distribuição global garante entrega confiável em todo o mundo, com suporte técnico abrangente e serviços de consultoria em engenharia.

SEU CONFIÁVEL AÇO

PARCEIRO DE MANUFATURA

Quick Inquiry

Indústrias que Atendemos

Soluções de aço profissionais em grandes indústrias

Qualificações e Certificações