20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

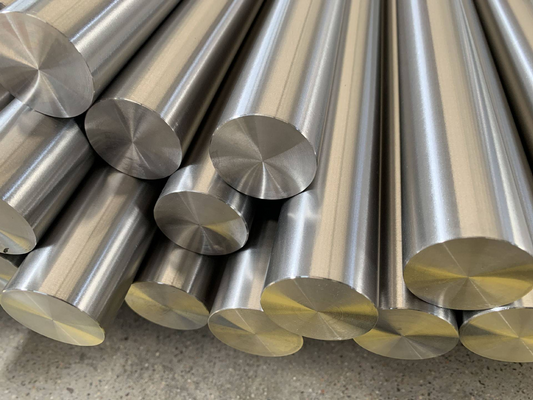

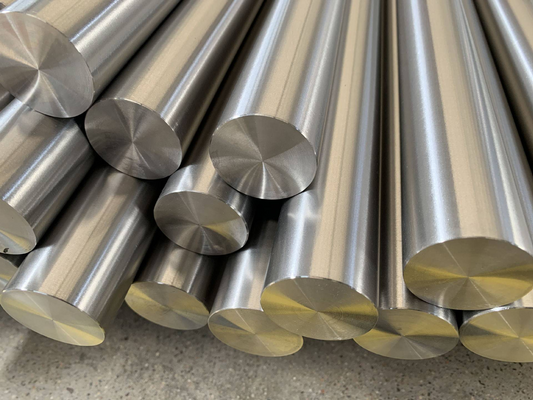

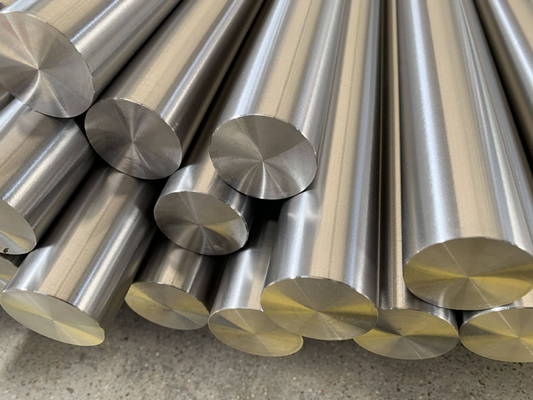

Product Overview

Metallurgical Characteristics

EN L360 is a microalloyed carbon-manganese steel featuring a fine-grained ferrite-pearlite microstructure. The controlled addition of niobium and vanadium provides precipitation strengthening and grain refinement, resulting in excellent strength-toughness balance. The low carbon equivalent ensures superior weldability without preheating requirements.

Manufacturing Process

MetalZenith employs advanced thermomechanical controlled processing (TMCP) for EN L360 production. The process begins with controlled reheating to 1200-1250°C, followed by multi-pass rolling in the austenite recrystallization and non-recrystallization regions. Accelerated cooling from 800-850°C to 500-550°C optimizes the final microstructure and mechanical properties.

Heat Treatment Options

Standard delivery condition is normalized or TMCP. For enhanced properties, quenching and tempering can be applied: austenitizing at 900-950°C, water quenching, followed by tempering at 600-650°C. This treatment increases yield strength while maintaining excellent impact toughness at low temperatures.

Quality Standards & Testing

All EN L360 products undergo comprehensive testing including chemical analysis per EN 10204, mechanical testing according to EN ISO 6892, and Charpy V-notch impact testing per EN ISO 148. Non-destructive testing includes ultrasonic examination, hydrostatic testing, and electromagnetic inspection to ensure defect-free delivery.

Welding Considerations

EN L360 exhibits excellent weldability with carbon equivalent values below 0.43%. Recommended welding processes include SMAW, GMAW, GTAW, and SAW. Preheat temperature of 50-100°C is sufficient for thick sections. Post-weld heat treatment is typically not required for most applications, reducing fabrication costs and complexity.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤ 0.22 |

| Manganese (Mn) | 1.40 - 1.65 |

| Silicon (Si) | 0.15 - 0.45 |

| Phosphorus (P) | ≤ 0.025 |

| Sulfur (S) | ≤ 0.015 |

| Chromium (Cr) | ≤ 0.30 |

| Nickel (Ni) | ≤ 0.30 |

| Molybdenum (Mo) | ≤ 0.15 |

| Copper (Cu) | ≤ 0.50 |

| Niobium (Nb) | 0.02 - 0.05 |

| Vanadium (V) | ≤ 0.06 |

| Titanium (Ti) | ≤ 0.04 |

| Aluminum (Al) | ≥ 0.015 |

| Carbon Equivalent (CE) | ≤ 0.43 |

⚙️ Mechanical Properties

| Property | Value |

|---|---|

| Yield Strength (Rp0.2) | 360 - 510 MPa |

| Tensile Strength (Rm) | 460 - 760 MPa |

| Elongation (A) | ≥ 22% |

| Yield to Tensile Ratio | ≤ 0.93 |

| Hardness (HV10) | 150 - 250 |

| Impact Energy (KV2) at 0°C | ≥ 40 J |

| Impact Energy (KV2) at -20°C | ≥ 27 J |

| Fatigue Limit (107 cycles) | 180 - 230 MPa |

| Fracture Toughness (KIC) | 150 - 200 MPa·m1/2 |

| Young's Modulus | 210 GPa |

| Poisson's Ratio | 0.30 |

| Shear Modulus | 81 GPa |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density | 7.85 g/cm³ |

| Melting Point | 1510 - 1540°C |

| Thermal Conductivity (20°C) | 54 W/m·K |

| Thermal Expansion Coefficient (20-100°C) | 12×10-6/K |

| Specific Heat Capacity | 500 J/kg·K |

| Electrical Resistivity (20°C) | 0.16 µΩ·m |

| Magnetic Permeability | Ferromagnetic |

| Curie Temperature | 770°C |

| Thermal Diffusivity | 13.7 mm²/s |

| Coefficient of Linear Expansion (0-100°C) | 11.5×10-6/K |

| Emissivity (oxidized surface) | 0.79 |

📏 Product Specifications

| Specification | Details |

|---|---|

| Available Forms | Seamless Pipes, Welded Pipes, Plates, Sheets, Coils, Bars |

| Pipe Outer Diameter | 21.3 - 1422 mm |

| Wall Thickness | 2.0 - 80 mm |

| Plate Thickness | 6 - 150 mm |

| Plate Width | 1500 - 4000 mm |

| Length | 6 - 18 m (or as required) |

| Standards Compliance | EN 10208-2, API 5L, ISO 3183, ASTM A106 |

| Surface Finish | Black, Pickled, Shot Blasted, Primer Coated |

| End Preparation | Plain End, Beveled End, Threaded |

| Dimensional Tolerance | ±1% (OD), ±10% (WT), ±6mm (Length) |

| Testing Requirements | Hydrostatic, Ultrasonic, Eddy Current, Radiographic |

| Delivery Condition | Normalized, TMCP, Quenched & Tempered |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing EN L360

Advanced Thermomechanical Processing

MetalZenith employs cutting-edge controlled rolling and accelerated cooling technologies to achieve optimal microstructural refinement in EN L360 steel, ensuring superior mechanical properties and dimensional consistency across all product forms.

Comprehensive Quality Control System

Our integrated quality management system features real-time chemical analysis, automated mechanical testing, and advanced non-destructive examination techniques, guaranteeing that every batch of EN L360 steel meets or exceeds international pipeline standards.

Global Supply Chain Excellence

MetalZenith's worldwide distribution network and flexible manufacturing capabilities enable rapid delivery of customized EN L360 steel products, from standard pipe specifications to specialized dimensions for unique pipeline applications.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications