20 Tahun Pengalaman | 1000+ Mitra Merek | Kustomisasi Penuh

Kami memiliki 20 tahun pengalaman industri, telah bermitra dengan lebih dari 1.000 merek, dan mendukung kebutuhan kustomisasi apa pun.

Technical Specifications

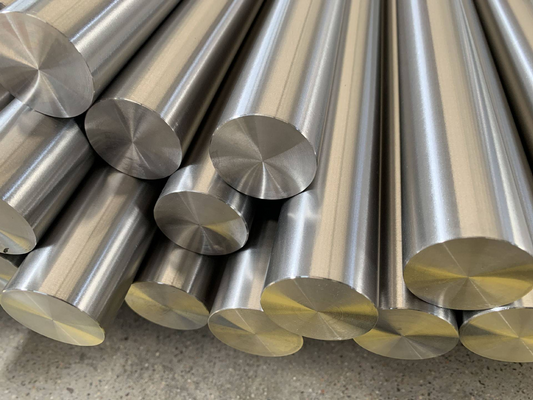

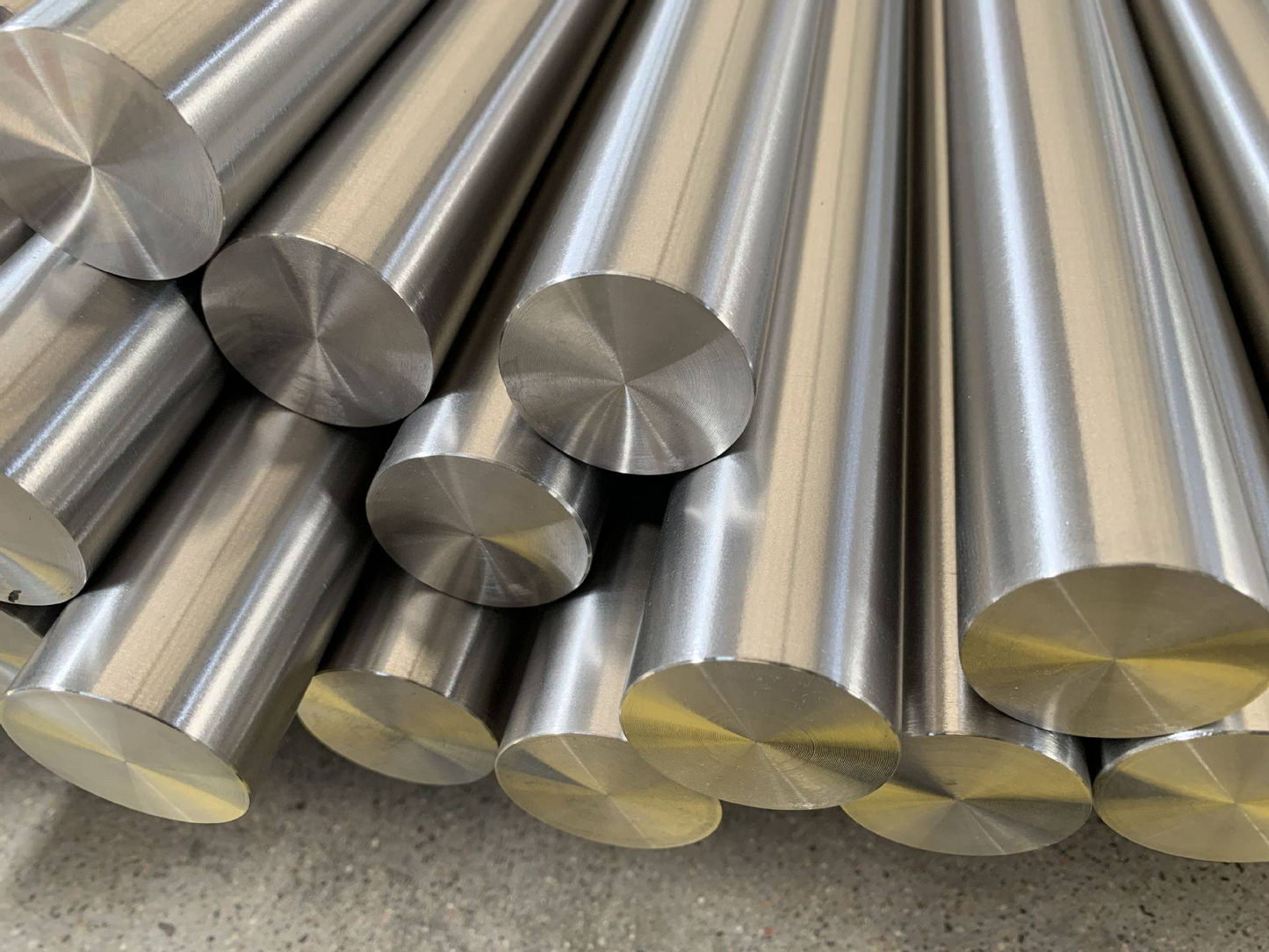

Product Overview

Karakteristik Metalurgi

Baja GB L450 memiliki mikrostruktur ferrite-pearlite yang halus yang dicapai melalui proses penggulungan terkontrol dan pendinginan yang dipercepat. Komposisi kimia yang dioptimalkan dengan elemen mikroaloy (Nb, V, Ti) memberikan keseimbangan kekuatan-kekakuan yang sangat baik dan kemampuan pengelasan yang superior. Baja ini menunjukkan ketahanan yang luar biasa terhadap retak yang disebabkan oleh hidrogen (HIC) dan retak korosi tegangan (SCC).

Proses Manufaktur

MetalZenith menggunakan teknologi pembuatan baja yang canggih termasuk peleburan tungku busur listrik, pemurnian ladle, dan pengecoran kontinu. TMCP (Thermo-Mechanical Controlled Processing) melibatkan penggulungan terkontrol pada suhu antara 850-950°C diikuti dengan pendinginan yang dipercepat untuk mencapai pemurnian butir yang optimal dan penguatan presipitasi. Perlakuan panas pasca-penggulungan dapat mencakup normalisasi pada 900-950°C untuk meningkatkan sifat mekanik.

Opsi Perlakuan Panas

Kondisi pengiriman standar adalah seperti digulung atau dinormalisasi. Perlakuan panas opsional termasuk pengurangan tegangan pada 580-650°C, pendinginan dan tempering untuk meningkatkan kekuatan, dan pendinginan terkontrol untuk meningkatkan ketangguhan. Suhu pra-panas pengelasan berkisar antara 50-150°C tergantung pada ketebalan dan kondisi lingkungan.

Standar & Pengujian Kualitas

Pengendalian kualitas yang komprehensif mencakup analisis kimia dengan spektrometri emisi optik, pengujian mekanik sesuai dengan GB/T 228 dan GB/T 229, pengujian ultrasonik untuk kekuatan internal, dan inspeksi dimensi. Sertifikasi pihak ketiga tersedia dari Lloyd's Register, DNV GL, dan lembaga klasifikasi terkemuka lainnya. Jejak material penuh dan sertifikat uji pabrik disediakan dengan setiap pengiriman.

🧪 Chemical Composition

| Elemen | Komposisi (%) |

|---|---|

| Karbon (C) | ≤ 0.16 |

| Mangan (Mn) | 1.40 - 1.65 |

| Silikon (Si) | 0.15 - 0.45 |

| Fosfor (P) | ≤ 0.025 |

| Belerang (S) | ≤ 0.015 |

| Kromium (Cr) | ≤ 0.30 |

| Nikel (Ni) | ≤ 0.30 |

| Molybdenum (Mo) | ≤ 0.25 |

| Tembaga (Cu) | ≤ 0.35 |

| Niobium (Nb) | 0.02 - 0.10 |

| Vanadium (V) | ≤ 0.06 |

| Titanium (Ti) | ≤ 0.04 |

| Aluminium (Al) | ≥ 0.015 |

| Nitrogen (N) | ≤ 0.012 |

⚙️ Mechanical Properties

| Properti | Nilai |

|---|---|

| Kekuatan Luluh (Rt0.5) | 450 - 570 MPa |

| Kekuatan Tarik (Rm) | 535 - 760 MPa |

| Panjang Regangan (A) | ≥ 21% |

| Rasio Kekuatan Luluh terhadap Tarik | ≤ 0.85 |

| Kekerasan (HV10) | 200 - 280 |

| Energi Dampak (KV2) pada 0°C | ≥ 150 J |

| Energi Dampak (KV2) pada -20°C | ≥ 120 J |

| Energi Dampak (KV2) pada -40°C | ≥ 80 J |

| Batas Kelelahan (10^7 siklus) | 240 MPa |

| Ketangguhan Patah (KIC) | 180 MPa·m^0.5 |

| Modulus Young | 210 GPa |

| Rasio Poisson | 0.30 |

🔬 Physical Properties

| Properti | Nilai |

|---|---|

| Kepadatan | 7.85 g/cm³ |

| Titik Leleh | 1510°C |

| Konduktivitas Termal (20°C) | 54 W/m·K |

| Koefisien Ekspansi Termal (20-100°C) | 12×10-6/K |

| Kapasitas Panas Spesifik | 500 J/kg·K |

| Resistivitas Listrik (20°C) | 0.16 µΩ·m |

| Permeabilitas Magnetik | Ferromagnetik |

| Suhu Curie | 770°C |

| Difusivitas Termal | 13.7 mm²/s |

| Koefisien Ekspansi Linier (0-100°C) | 11.5×10-6/K |

📏 Product Specifications

| Spesifikasi | Detail |

|---|---|

| Bentuk yang Tersedia | Pelat, Lembaran, Gulungan, Pipa, Tabung, Batang |

| Ketebalan Pelat | 6 - 100 mm |

| Ketebalan Lembaran | 1.5 - 6 mm |

| Ketebalan Gulungan | 2 - 25 mm |

| Rentang Lebar | 1000 - 4000 mm |

| Rentang Panjang | 2000 - 18000 mm |

| Diameter Pipa | 219 - 1422 mm |

| Ketebalan Dinding Pipa | 6 - 80 mm |

| Kepatuhan Standar | GB/T 9711, API 5L, ISO 3183, EN 10208 |

| Penyelesaian Permukaan | Dibuat Panas, Dinormalisasi, TMCP |

| Toleransi Dimensi | ±0.5% (ketebalan), ±5mm (lebar/panjang) |

| Kondisi Ujung | Ujung Pabrik, Ujung Potong, Ujung Dipangkas |

| Standar Pengujian | GB/T 228, GB/T 229, GB/T 232, ASTM A370 |

Mari Kita Ciptakan Kesuksesan untuk Proyek Anda

Tim Profesional, Produk Premium, Layanan Lengkap - Keberhasilan Proyek Anda adalah Misi Kami

Our Advantages in Processing GB L450

Teknologi TMCP Lanjutan

MetalZenith menggunakan pemrosesan Termo-Mekanis Terkontrol (TMCP) yang mutakhir dengan kontrol suhu yang tepat dan sistem pendinginan yang dipercepat, mencapai pemurnian butir yang optimal dan peningkatan sifat mekanik sambil mempertahankan karakteristik las yang sangat baik.

Pengendalian Kualitas yang Komprehensif

Sistem manajemen kualitas terintegrasi kami dilengkapi dengan pengujian ultrasonik canggih, analisis kimia otomatis, dan pemantauan sifat mekanik secara real-time. Setiap kumparan dan pelat menjalani inspeksi 100% dengan dokumentasi jejak penuh dan sertifikasi pihak ketiga.

Kemampuan Kustomisasi Fleksibel

MetalZenith menawarkan opsi kustomisasi yang luas termasuk toleransi dimensi spesifik, penyelesaian permukaan, dan persyaratan sifat mekanis. Rantai pasokan global kami memastikan pengiriman yang dapat diandalkan dengan logistik tepat waktu dan layanan dukungan teknis yang komprehensif.

ANDA YANG DIPERCAYA BAJA

MITRA MANUFAKTUR

Pertanyaan Cepat

Industri yang Kami Layani

Solusi baja profesional di berbagai industri

Kualifikasi & Sertifikasi