20 Tahun Pengalaman | 1000+ Mitra Merek | Kustomisasi Penuh

Kami memiliki 20 tahun pengalaman industri, telah bermitra dengan lebih dari 1.000 merek, dan mendukung kebutuhan kustomisasi apa pun.

Technical Specifications

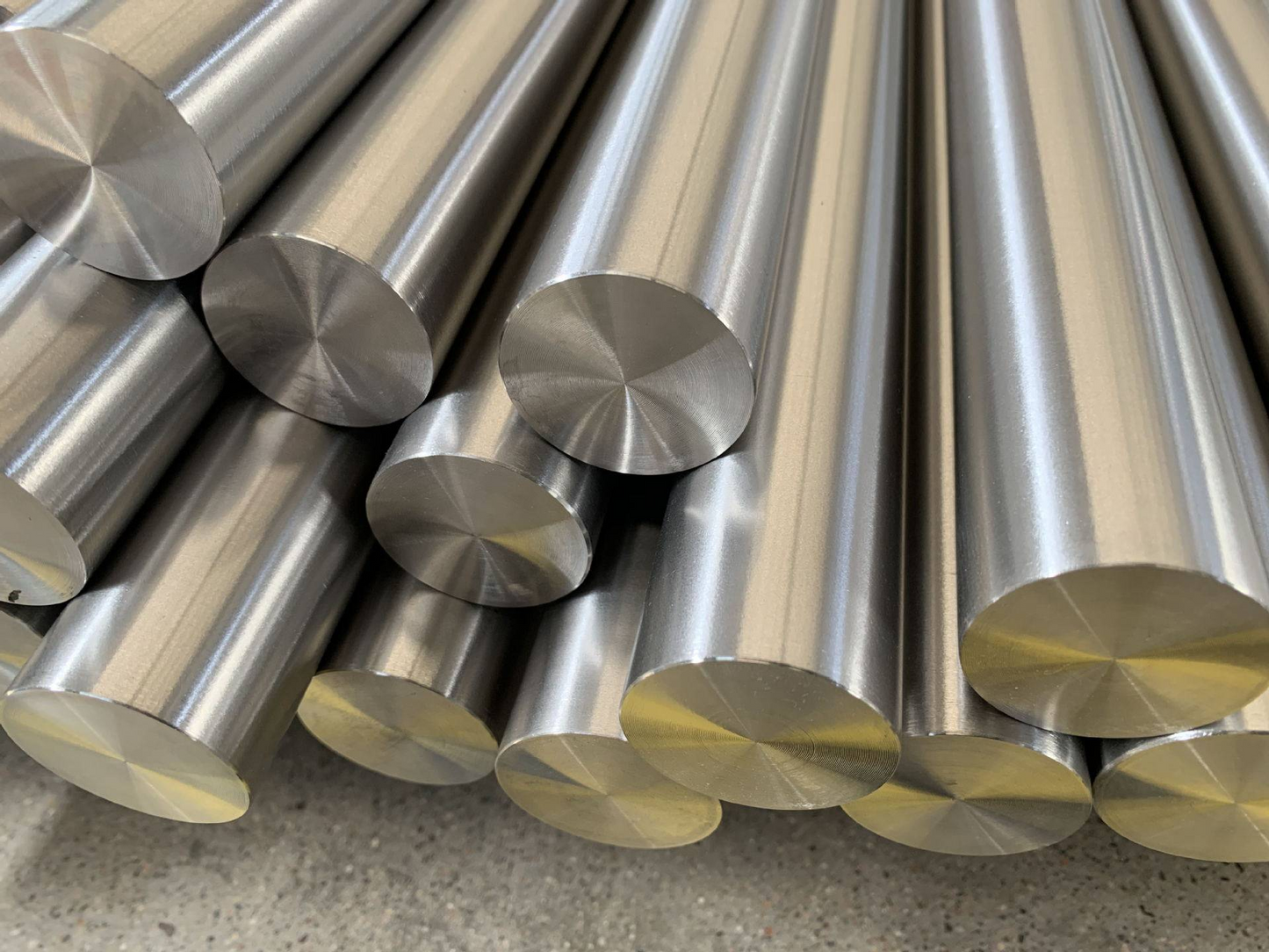

Product Overview

Karakteristik Metalurgi

37MnB4 adalah baja boron paduan rendah yang dirancang untuk aplikasi pembentukan panas di mana komponen dengan kekuatan ultra-tinggi diperlukan. Penambahan boron secara signifikan meningkatkan kemampuan pengerasan, memungkinkan pengerasan menyeluruh pada bagian tebal dengan media pendinginan yang relatif sederhana. Baja ini menunjukkan kemampuan pembentukan panas yang sangat baik pada suhu antara 900-950°C, menjadikannya ideal untuk operasi pengerasan tekan.

Proses Perlakuan Panas

Perlakuan panas yang optimal melibatkan austenitisasi pada 900-950°C diikuti dengan pendinginan cepat untuk mencapai transformasi martensit. Operasi pembentukan panas biasanya melibatkan pemanasan blanko hingga suhu austenitisasi, pembentukan dalam cetakan, dan pendinginan simultan untuk mencapai sifat akhir. Tempering pada 150-200°C dapat diterapkan untuk mengurangi kerapuhan sambil mempertahankan tingkat kekuatan yang tinggi.

Proses Manufaktur di MetalZenith

MetalZenith memproduksi 37MnB4 melalui peleburan tungku busur listrik dengan penambahan boron yang tepat selama metalurgi sekunder. Baja ini menjalani penghilangan gas vakum untuk meminimalkan kandungan hidrogen dan pembentukan inklusi. Proses penggulungan dan pendinginan yang terkontrol memastikan pengembangan mikrostruktur yang optimal dan sifat mekanik yang konsisten di seluruh penampang produk.

Standar Kualitas & Pengujian

Semua produk 37MnB4 menjalani pengujian komprehensif termasuk analisis kimia melalui spektrometri emisi optik, verifikasi sifat mekanik melalui pengujian tarik dan kekerasan, serta pemeriksaan mikrostruktur. Pengujian kemampuan pengerasan memastikan kinerja yang konsisten dalam aplikasi pembentukan panas. MetalZenith mempertahankan jejak penuh dari bahan baku hingga pengiriman produk akhir, dengan sertifikat kepatuhan yang disediakan untuk semua pengiriman.

🧪 Chemical Composition

| Elemen | Komposisi (%) |

|---|---|

| Karbon (C) | 0.34 - 0.40 |

| Mangan (Mn) | 1.20 - 1.50 |

| Silikon (Si) | 0.15 - 0.35 |

| Fosfor (P) | ≤ 0.025 |

| Belerang (S) | ≤ 0.025 |

| Krom (Cr) | 0.15 - 0.35 |

| Boron (B) | 0.0008 - 0.0050 |

| Aluminium (Al) | 0.020 - 0.060 |

| Nitrogen (N) | ≤ 0.012 |

| Titanium (Ti) | 0.020 - 0.050 |

⚙️ Mechanical Properties

| Properti | Nilai |

|---|---|

| Kekuatan Tarik (Sebagaimana Dikirim) | 600 - 750 MPa |

| Kekuatan Luluh (Sebagaimana Dikirim) | 350 - 450 MPa |

| Panjang Regangan (Sebagaimana Dikirim) | ≥ 20% |

| Kekerasan (Sebagaimana Dikirim) | 180 - 220 HBW |

| Kekuatan Tarik (Setelah Pembentukan Panas) | ≥ 1500 MPa |

| Kekuatan Luluh (Setelah Pembentukan Panas) | ≥ 1200 MPa |

| Panjang Regangan (Setelah Pembentukan Panas) | ≥ 6% |

| Kekerasan (Setelah Pembentukan Panas) | 450 - 520 HV |

| Energi Impak (Charpy V-notch) | ≥ 27 J pada 20°C |

| Modulus Young | 210 GPa |

🔬 Physical Properties

| Properti | Nilai |

|---|---|

| Kepadatan | 7.85 g/cm³ |

| Titik Leleh | 1480 - 1520°C |

| Konduktivitas Termal (20°C) | 42 W/m·K |

| Koefisien Ekspansi Termal (20-100°C) | 11.5×10-6/K |

| Kapasitas Panas Spesifik | 460 J/kg·K |

| Resistivitas Listrik (20°C) | 0.18 µΩ·m |

| Permeabilitas Magnetik | Ferromagnetik |

| Suhu Curie | 770°C |

| Rasio Poisson | 0.27 - 0.30 |

| Suhu Austenisasi | 900 - 950°C |

📏 Product Specifications

| Spesifikasi | Opsi Tersedia |

|---|---|

| Bentuk Produk | Lembaran panas, Lembaran dingin, Gulungan, Blanks |

| Rentang Ketebalan | 0.8 - 6.0 mm |

| Rentang Lebar | 600 - 2000 mm |

| Rentang Panjang | 1000 - 6000 mm (lembaran) |

| Berat Gulungan | Hingga 25 ton |

| Finishing Permukaan | Dihasilkan panas, Diasamkan, Diminyak, Dilapisi Al-Si |

| Toleransi Ketebalan | ± 0.05 mm |

| Toleransi Lebar | ± 2.0 mm |

| Kepatuhan Standar | EN 10083-3, JIS G4053, ASTM A29 |

| Kondisi Ujung | Ujung pabrik, Ujung dipangkas, Ujung dipotong |

Mari Kita Ciptakan Kesuksesan untuk Proyek Anda

Tim Profesional, Produk Premium, Layanan Lengkap - Keberhasilan Proyek Anda adalah Misi Kami

Our Advantages in Processing 37MnB4

Teknologi Mikroaloy Boron Lanjutan

MetalZenith menggunakan teknik penambahan boron yang presisi dan proses pendinginan yang terkontrol untuk mencapai distribusi boron yang optimal dan peningkatan kemampuan pengerasan, memastikan sifat mekanik yang konsisten dan kinerja pembentukan panas yang superior di seluruh batch produk.

Sistem Pengendalian Kualitas yang Komprehensif

Fasilitas pengujian mutakhir kami mencakup spektrometer canggih, mesin pengujian universal, dan peralatan metalografi untuk memverifikasi komposisi kimia, sifat mekanik, dan integritas mikrostruktur, menjamin kepatuhan terhadap standar internasional.

Produksi Fleksibel & Pasokan Global

MetalZenith menawarkan dimensi yang disesuaikan, penyelesaian permukaan, dan jadwal pengiriman melalui fasilitas produksi terintegrasi dan jaringan distribusi global kami, menyediakan pengiriman tepat waktu dan dukungan teknis untuk aplikasi khusus di seluruh dunia.

ANDA YANG DIPERCAYA BAJA

MITRA MANUFAKTUR

Pertanyaan Cepat

Industri yang Kami Layani

Solusi baja profesional di berbagai industri

Kualifikasi & Sertifikasi