20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

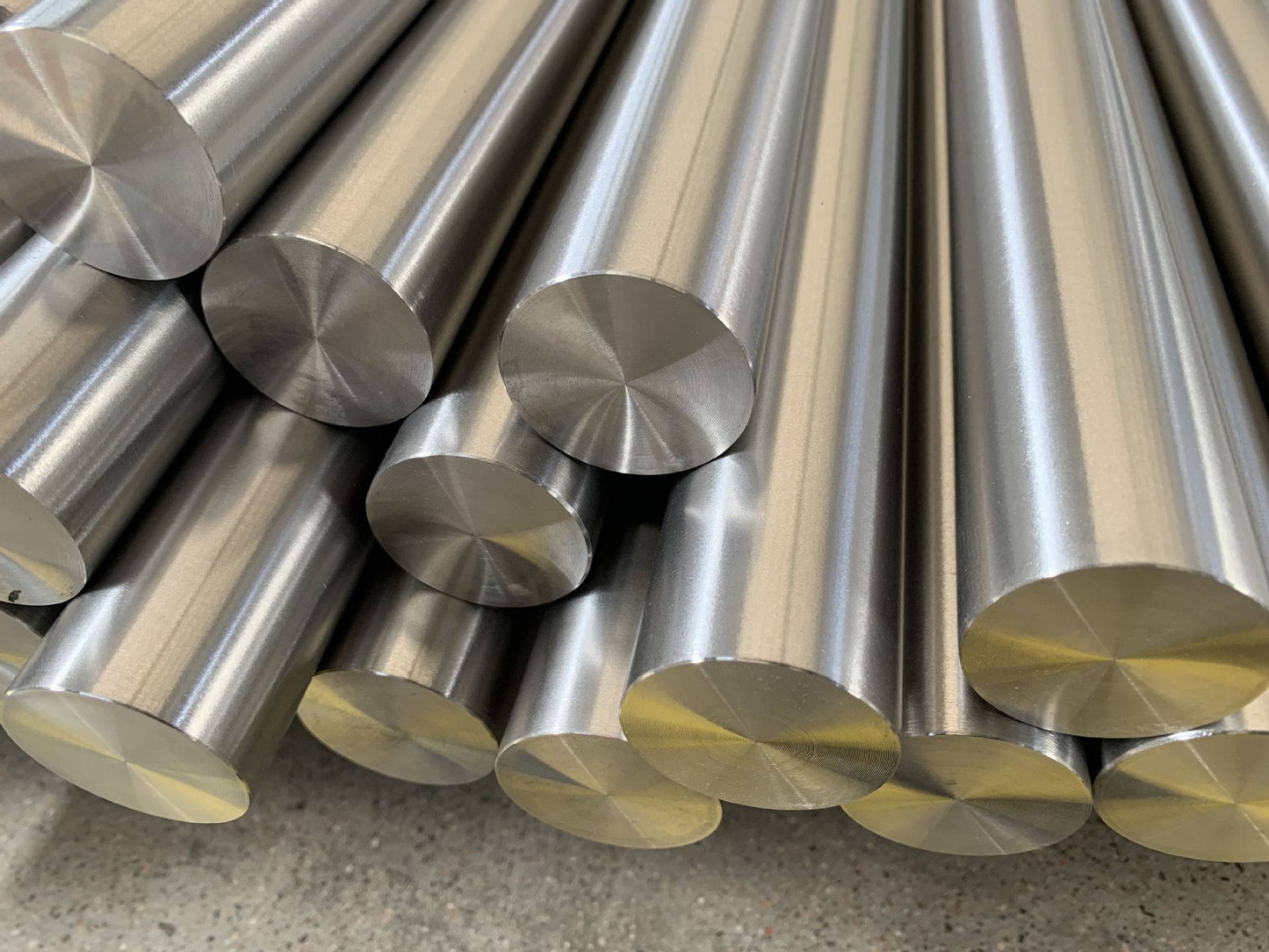

Product Overview

الخصائص المعدنية

يظهر UNS S32750 بنية ميكروية مزدوجة متوازنة تتكون من حوالي 50% من الأوستنيت و50% من الفريت. توفر هذه البنية الفريدة نسبة استثنائية من القوة إلى الوزن ومقاومة متفوقة لتصدع التآكل الناتج عن الضغط، والتآكل النقطي، وتآكل الشقوق. يعزز محتوى النيتروجين العالي كل من الخصائص الميكانيكية ومقاومة التآكل، بينما تحسن إضافات الموليبدينوم بشكل كبير من عدد مقاومة التآكل النقطي (PREN ≥ 40).

عملية المعالجة الحرارية

تستخدم MetalZenith عملية تلدين دقيقة عند 1020-1100°C تليها تبريد سريع بالماء لتحقيق توازن مثالي في البنية الميكروية. تمنع عملية التبريد المتحكم فيها ترسيب الطور بين المعدني الضار مع الحفاظ على نسبة الأوستنيت والفريت المرغوبة. قد يتم تطبيق تخفيف الضغط بعد المعالجة الحرارية عند 300-400°C لتطبيقات محددة تتطلب استقرار الأبعاد.

تميز التصنيع

تبدأ عملية التصنيع المتقدمة لدينا بالذوبان بالتحريض في الفراغ باستخدام مواد خام عالية الجودة، تليها إعادة الذوبان بالكهرباء لتحسين النظافة. يتم التحكم في عمليات العمل الساخن بعناية ضمن نطاق درجة حرارة 950-1200°C للحفاظ على البنية الميكروية المثلى. تشمل قدرات العمل البارد التشغيل الدقيق، والتشكيل، واللحام باستخدام تقنيات متخصصة للفولاذ المقاوم للصدأ المزدوج.

الامتثال لمعايير الجودة

تحافظ MetalZenith على الالتزام الصارم بالمعايير الدولية بما في ذلك ASTM A182/A240/A479، EN 10088-2/10088-3، وJIS G4303. يشمل نظام إدارة الجودة لدينا التحليل الكيميائي باستخدام طيف الانبعاث الضوئي، والاختبارات الميكانيكية وفقًا لـ ASTM E8/E23، واختبارات التآكل بما في ذلك ASTM G48، وفحص شامل للبنية الميكروية. تخضع جميع المنتجات لفحص أبعاد بنسبة 100% واختبارات غير مدمرة عند الطلب، مما يضمن جودة وأداء متسقين في التطبيقات الحرجة.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| الكربون (C) | ≤ 0.030 |

| المنغنيز (Mn) | ≤ 1.20 |

| السيليكون (Si) | ≤ 0.80 |

| الفوسفور (P) | ≤ 0.035 |

| الكبريت (S) | ≤ 0.020 |

| الكروم (Cr) | 24.0 - 26.0 |

| النيكل (Ni) | 6.0 - 8.0 |

| الموليبدينوم (Mo) | 3.0 - 5.0 |

| النيتروجين (N) | 0.24 - 0.32 |

| النحاس (Cu) | ≤ 0.50 |

| التنجستن (W) | ≤ 0.50 |

| الحديد (Fe) | التوازن |

⚙️ Mechanical Properties

| الخاصية | القيمة |

|---|---|

| قوة الشد (Rm) | ≥ 800 MPa |

| قوة العائد 0.2% (Rp0.2) | ≥ 550 MPa |

| التمدد (A5) | ≥ 15% |

| الصلابة (HRC) | ≤ 32 |

| طاقة الصدمة (KV) عند 20°C | ≥ 60 J |

| طاقة الصدمة (KV) عند -40°C | ≥ 40 J |

| معامل يونغ | 200 GPa |

| معامل القص | 77 GPa |

| نسبة بواسون | 0.30 |

| حد التعب (10&sup7; دورات) | 350 MPa |

🔬 Physical Properties

| الخاصية | القيمة |

|---|---|

| الكثافة | 7.8 g/cm³ |

| نقطة الانصهار | 1300-1370°C |

| التوصيل الحراري عند 20°C | 17 W/m·K |

| التوصيل الحراري عند 100°C | 19 W/m·K |

| التمدد الحراري (20-100°C) | 13.0×10-6/K |

| التمدد الحراري (20-200°C) | 13.5×10-6/K |

| السعة الحرارية النوعية | 480 J/kg·K |

| المقاومة الكهربائية عند 20°C | 0.85 µΩ·m |

| نفاذية مغناطيسية | 1.02 µH/m |

| درجة حرارة كوري | -50°C |

📏 Product Specifications

| المواصفات | الخيارات المتاحة |

|---|---|

| أشكال المنتجات | قضبان دائرية، قضبان مربعة، قضبان مسطحة، ألواح، صفائح، أنابيب، مواسير، تشكيلات |

| قطر القضيب الدائري | 6mm - 300mm |

| سمك اللوح | 3mm - 100mm |

| سمك الورقة | 0.5mm - 6mm |

| قطر الأنبوب الخارجي | 6mm - 219mm |

| المعايير | ASTM A182, A240, A479, A789, A790, EN 10088, JIS G4303 |

| تشطيب السطح | مدرفل على الساخن، مدرفل على البارد، مشعع لامع، مخلل، مصقول |

| الت tolerance | ±0.1mm للمنتجات الدقيقة، tolerances القياسية حسب ASTM/EN |

| الطول | حتى 12 متر (أطوال مخصصة متاحة) |

| الشهادات | شهادة اختبار المصنع، EN 10204 3.1/3.2، NACE MR0175 |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing UNS S32750

تكنولوجيا الصهر بالفراغ المتقدمة

MetalZenith تستخدم تقنيات الصهر بالتحريض الفراغي المتطورة (VIM) وإعادة الصهر بالتيار الكهربائي (ESR) لتحقيق تجانس كيميائي استثنائي وتقليل الشوائب في UNS S32750. تضمن عملياتنا في جو محكم التحكم محتوى نيتروجين مثالي وتوازن دقيق في الطور للحصول على مقاومة تآكل وخصائص ميكانيكية متفوقة.

أنظمة مراقبة الجودة الشاملة

تتميز منشآتنا الحاصلة على شهادة ISO 9001:2015 بمختبرات اختبار متقدمة مزودة بأجهزة تحليل PMI، وآلات اختبار عالمية، ومعدات اختبار التآكل. تخضع كل دفعة لتحليل كيميائي صارم، واختبارات ميكانيكية، وفحص للميكروهيكل لضمان الامتثال للمعايير الدولية ومواصفات العملاء.

معالجة مخصصة والإمداد العالمي

يقدم MetalZenith قدرات تخصيص واسعة تشمل التشغيل الدقيق، وتحسين معالجة الحرارة، والتشطيبات السطحية المتخصصة. يضمن شبكتنا العالمية لسلسلة التوريد تسليم موثوق في جميع أنحاء العالم، مدعومًا بالوثائق الفنية الشاملة والدعم الهندسي للتطبيقات الحرجة.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات