20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

Product Overview

الخصائص المعدنية

الفولاذ المقاوم للصدأ الفيريتك يظهر هيكل بلوري مكعب مركزي (BCC) مع محتوى الكروم يتراوح من 10.5% إلى 18%. يوفر الهيكل المجهري الفيريتك مقاومة ممتازة لتصدع التآكل الناتج عن الضغط ويحافظ على الخصائص المغناطيسية. غياب النيكل يجعل هذه الدرجة فعالة من حيث التكلفة بينما توفر مقاومة جيدة للتآكل في البيئات المؤكسدة.

عملية المعالجة الحرارية

تستخدم MetalZenith التلدين المنضبط عند 750-850 درجة مئوية تليها تبريد سريع لمنع ترسيب الكربيد والحفاظ على مقاومة التآكل المثلى. تشمل عملية المعالجة الحرارية المتخصصة لدينا تلدين تخفيف الضغط ومعدلات تبريد منضبطة لتقليل نمو الحبيبات وتحسين الخصائص الميكانيكية.

عملية التصنيع

تشمل عملية التصنيع المتقدمة لدينا صهر التحريض في الفراغ، الصب المستمر، والدرفلة الساخنة المنضبطة مع التحكم الدقيق في درجة الحرارة. تضمن خطوط التلدين والتنظيف الحديثة في MetalZenith جودة سطح ممتازة ومقاومة للتآكل. تعزز معالجة التمرير النهائية تشكيل طبقة أكسيد واقية.

اختبارات الجودة المتخصصة

تجري MetalZenith اختبارات شاملة بما في ذلك قياس إمكانيات التآكل في محلول NaCl بنسبة 3.5%، واختبار تآكل الحبيبات ASTM A262 Practice A، وتقييم تآكل الضغط في محلول MgCl2 المغلي، وتحليل سمك فيلم التمرير باستخدام الإيليبسومتر. تضمن هذه الاختبارات الأداء الأمثل في البيئات التآكلية.

اعتبارات خاصة بالتطبيقات

بالنسبة لتطبيقات المعدات الكيميائية، يوفر الفولاذ المقاوم للصدأ الفيريتك لدينا مقاومة ممتازة لحمض النيتريك والأحماض العضوية. في تطبيقات صناعة المواد الغذائية، يتوافق المادة مع متطلبات FDA مع خصائص نظافة وتنظيف ممتازة. تستفيد تطبيقات الأجهزة الطبية من التوافق الحيوي ومقاومة التعقيم. تستخدم التطبيقات البحرية مقاومة الكلور الممتازة، بينما تستفيد التطبيقات المعمارية من الجاذبية الجمالية ومتطلبات الصيانة المنخفضة.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| الكربون (C) | ≤ 0.08 |

| الكروم (Cr) | 10.5 - 18.0 |

| المنغنيز (Mn) | ≤ 1.00 |

| السيليكون (Si) | ≤ 1.00 |

| الفوسفور (P) | ≤ 0.040 |

| الكبريت (S) | ≤ 0.030 |

| النيكل (Ni) | ≤ 0.60 |

| الموليبدينوم (Mo) | 0.75 - 1.25 |

⚙️ Mechanical Properties

| الخاصية | القيمة |

|---|---|

| قوة العائد (ميغاباسكال) | ≥ 275 |

| قوة الشد (ميغاباسكال) | 415 - 585 |

| التمدد (%) | ≥ 20 |

| الصلابة (HRB) | ≤ 88 |

| معدل التآكل (مم/سنة) | < 0.1 في البيئات المعتدلة |

| إمكانات التآكل (ملي فولت) | > 200 مقابل SCE |

🔬 Physical Properties

| الخاصية | القيمة |

|---|---|

| الكثافة (غ/سم³) | 7.70 - 7.80 |

| نقطة الانصهار (°م) | 1425 - 1510 |

| الموصلية الحرارية (W/m·K) | 25.0 عند 100°C |

| التوسع الحراري (×10??/K) | 10.4 عند 20-100°C |

| المقاومة الكهربائية (μΩ·cm) | 60 عند 20°C |

| معامل المرونة (GPa) | 200 |

📏 Product Specifications

| المواصفات | التفاصيل |

|---|---|

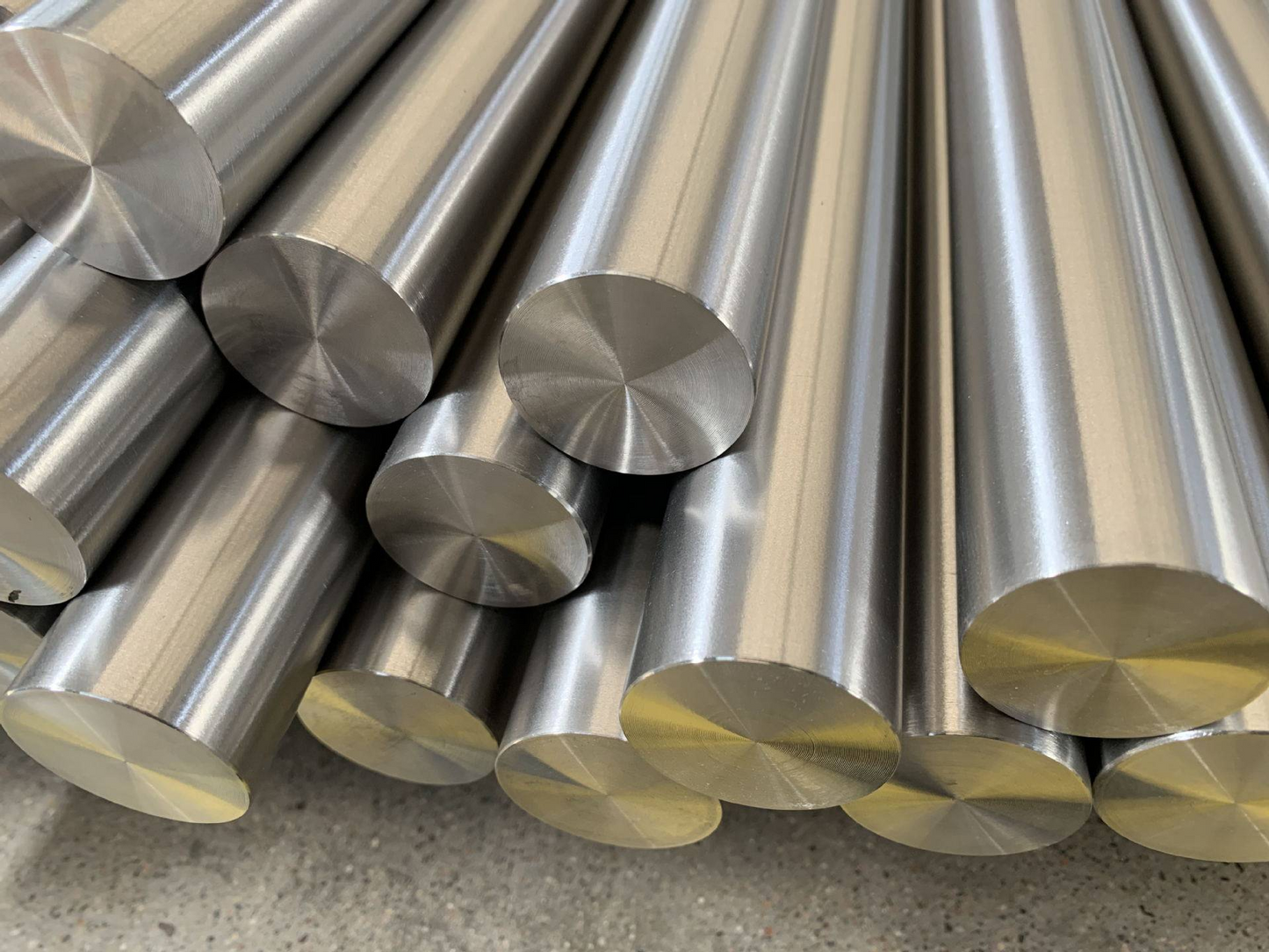

| الأشكال المتاحة | أوراق، لوحات، لفات، قضبان، أنابيب، سلك |

| نطاق السماكة | 0.4 - 50 مم |

| نطاق العرض | 600 - 2000 مم |

| نطاق الطول | 2000 - 6000 مم |

| الامتثال للمعايير | ASTM A240، EN 10088، JIS G4305 |

| تشطيب السطح | 2B، BA، No.4، HL، مرآة |

| حالة المعالجة الحرارية | مخمرة ومخللة |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing الفولاذ المقاوم للصدأ الفيريتك

تكنولوجيا الصهر بالفراغ المتقدمة

MetalZenith تستخدم تقنية الصهر بالتحريض الفراغي المتطورة مع التحكم الدقيق في درجة الحرارة ومعالجة الأجواء المسيطر عليها لتحقيق توزيع مثالي للكروم وتقليل الشوائب. تضمن عملياتنا المعدنية المتقدمة هيكل حبيبي متسق ومقاومة فائقة للتآكل في جميع أنحاء المادة.

اختبار التآكل الشامل

تجري MetalZenith اختبارات تآكل شاملة تشمل قياس إمكانات التآكل، واختبار التآكل بين الحبيبات وفقًا لمعيار ASTM A262، وتقييم تشقق التآكل الناتج عن الإجهاد في البيئات المحتوية على الكلور، وتحليل سمك فيلم التمرير باستخدام تقنية XPS. تضمن اختباراتنا الدقيقة أداءً مثاليًا ضد التآكل في ظروف الخدمة.

معالجة مخصصة ودعم فني

تقدم MetalZenith خدمات معالجة مخصصة شاملة تشمل التلدين الدقيق، والتشطيب السطحي، والمعالجات الحرارية المتخصصة. يوفر مهندسونا المعدنيون الدعم الفني لمتطلبات التطبيقات المحددة، مما يضمن الأداء الأمثل في التطبيقات الكيميائية، والغذائية، والطبية، والبحرية.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات