20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

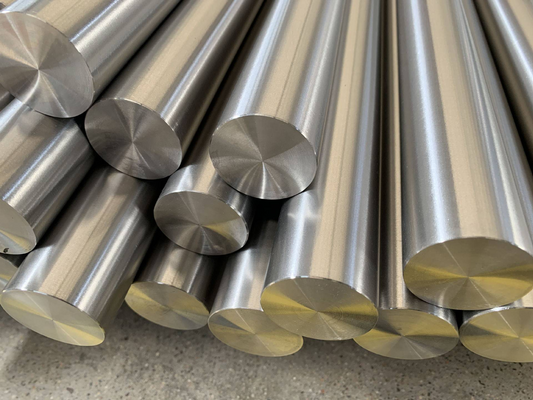

Product Overview

الخصائص المعدنية

EN S550 هو فولاذ هيكلي عالي القوة ومنخفض السبيكة (HSLA) يتميز بتركيب ميكروهيكلي دقيق تم تحقيقه من خلال معالجة حرارية ميكانيكية مسيطر عليها. يظهر الفولاذ تركيبًا ميكروهيكليًا يتكون بشكل أساسي من الفريت والباينيت مع مزيج ممتاز من القوة والصلابة وقابلية اللحام. تضمن معالجة MetalZenith المتقدمة تحسين حبيبات الفولاذ من خلال عناصر السبيكة الدقيقة بما في ذلك الفاناديوم والنيوبيوم والتيتانيوم.

عملية المعالجة الحرارية

تشمل عملية التصنيع لدينا الدرفلة المسيطر عليها عند درجات حرارة تتراوح بين 900-1100°C تليها تبريد متسارع لتحقيق الخصائص الميكانيكية المطلوبة. يتم التحكم بدقة في عملية التبريد والتسخين مع الأوستنيتيز عند 900-950°C، تليها التبريد بالماء والتسخين عند 580-650°C. تضمن هذه الدورة الحرارية توازنًا مثاليًا بين القوة والصلابة واستقرار الأبعاد.

تميز التصنيع

تستخدم MetalZenith أفران قوس كهربائي متطورة مع قدرات تنقية ثانوية بما في ذلك فرن الصب والتفريغ الفراغي. تضمن مرافق الصب المستمر والدرفلة الساخنة تركيبة كيميائية وخصائص ميكانيكية متسقة في جميع أنحاء المقطع العرضي. تراقب أنظمة التحكم في العمليات المتقدمة درجة الحرارة ومعلمات الدرفلة ومعدلات التبريد في الوقت الحقيقي.

معايير الجودة والاختبار

تخضع كل دفعة لاختبارات شاملة بما في ذلك التحليل الكيميائي عبر طيف الانبعاث الضوئي، واختبار الشد وفقًا لمعيار EN ISO 6892-1، واختبار الصدمات باستخدام شريحة شاربي وفقًا لمعيار EN ISO 148-1، واختبار الصلابة وفقًا لمعيار EN ISO 6506. تضمن اختبارات الموجات فوق الصوتية وفحص الجسيمات المغناطيسية سلامة داخلية. يتوافق نظام إدارة الجودة لدينا مع معايير ISO 9001:2015 وISO 14001:2015 وOHSAS 18001، مما يضمن جودة المنتج المتسقة والمسؤولية البيئية.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| الكربون (C) | ≤ 0.12 |

| المنغنيز (Mn) | 1.60 - 2.10 |

| السيليكون (Si) | 0.10 - 0.50 |

| الفوسفور (P) | ≤ 0.020 |

| الكبريت (S) | ≤ 0.010 |

| الكروم (Cr) | 0.30 - 1.25 |

| النيكل (Ni) | 0.30 - 2.00 |

| الموليبدينوم (Mo) | 0.20 - 0.60 |

| النحاس (Cu) | ≤ 0.50 |

| الألمنيوم (Al) | ≥ 0.015 |

| الفاناديوم (V) | 0.02 - 0.12 |

| النيوبوم (Nb) | 0.015 - 0.060 |

| التيتانيوم (Ti) | 0.006 - 0.050 |

| البورون (B) | 0.0008 - 0.005 |

⚙️ Mechanical Properties

| الخاصية | القيمة |

|---|---|

| قوة العائد (Rp0.2) | ≥ 550 MPa |

| قوة الشد (Rm) | 640 - 820 MPa |

| التمدد (A5) | ≥ 17% |

| طاقة الصدمة (KV عند -40°C) | ≥ 30 J |

| صلابة برينل (HBW) | 180 - 250 |

| معامل يونغ | 210 GPa |

| نسبة بواسون | 0.30 |

| حد التعب (107 دورة) | 275 MPa |

| صلابة الكسر (KIC) | 120 MPa·m1/2 |

| تقليل المساحة (Z) | ≥ 50% |

🔬 Physical Properties

| الخاصية | القيمة |

|---|---|

| الكثافة | 7.85 g/cm³ |

| نقطة الانصهار | 1480 - 1520°C |

| الموصلية الحرارية (20°C) | 42 W/m·K |

| معامل التمدد الحراري (20-100°C) | 12.5×10-6/K |

| السعة الحرارية النوعية | 460 J/kg·K |

| المقاومة الكهربائية (20°C) | 0.18 µΩ·m |

| نفاذية مغناطيسية | مغناطيسي حديدي |

| درجة حرارة كوري | 770°C |

| الانتشار الحراري | 11.6 mm²/s |

| الانبعاثية (السطح المؤكسد) | 0.85 |

📏 Product Specifications

| المواصفات | التفاصيل |

|---|---|

| الأشكال المتاحة | ألواح، صفائح، قضبان، ملفات، أنابيب |

| نطاق سمك اللوح | 8 - 100 مم |

| نطاق سمك الصفائح | 3 - 8 مم |

| أقصى أبعاد اللوح | 3000 × 12000 مم |

| نطاق قطر القضبان | 10 - 300 مم |

| الامتثال للمعايير | EN 10025-6، ASTM A514، JIS G3106 |

| تشطيب السطح | مدرفل على الساخن، مخلل، مطرقة بالرصاص |

| تحمل الأبعاد | ±0.5 مم (سمك)، ±2 مم (عرض/طول) |

| حالة الحافة | حافة مطحنة، حافة مقطوعة، قطع اللهب |

| حالة التسليم | مبرد ومقسى (Q+T) |

| شهادات الاختبار | EN 10204 النوع 3.1، 3.2 متاحة |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing S550

معالجة حرارية ميكانيكية متقدمة

تستخدم MetalZenith تقنية الدرفلة المتحكم بها والتبريد المعجل لتحقيق التركيب المجهري والخصائص الميكانيكية المثلى في EN S550، مما يضمن نسب قوة إلى وزن متفوقة وقابلية لحام ممتازة.

نظام شامل لمراقبة الجودة

نظام إدارة الجودة المتكامل لدينا يشمل التحليل الكيميائي في الوقت الحقيقي، والاختبارات الميكانيكية الآلية، وطرق الاختبار غير التدميرية المتقدمة، مما يضمن خصائص المواد المتسقة والتتبع الكامل لكل دفعة من المنتجات.

معالجة مخصصة والإمداد العالمي

تقدم MetalZenith إمكانيات تخصيص واسعة تشمل خدمات القطع الدقيق، والتشكيل، ومعالجة السطح، مدعومة بشبكة اللوجستيات العالمية لدينا لضمان التسليم في الوقت المناسب لمنتجات EN S550 في جميع أنحاء العالم.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات