20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

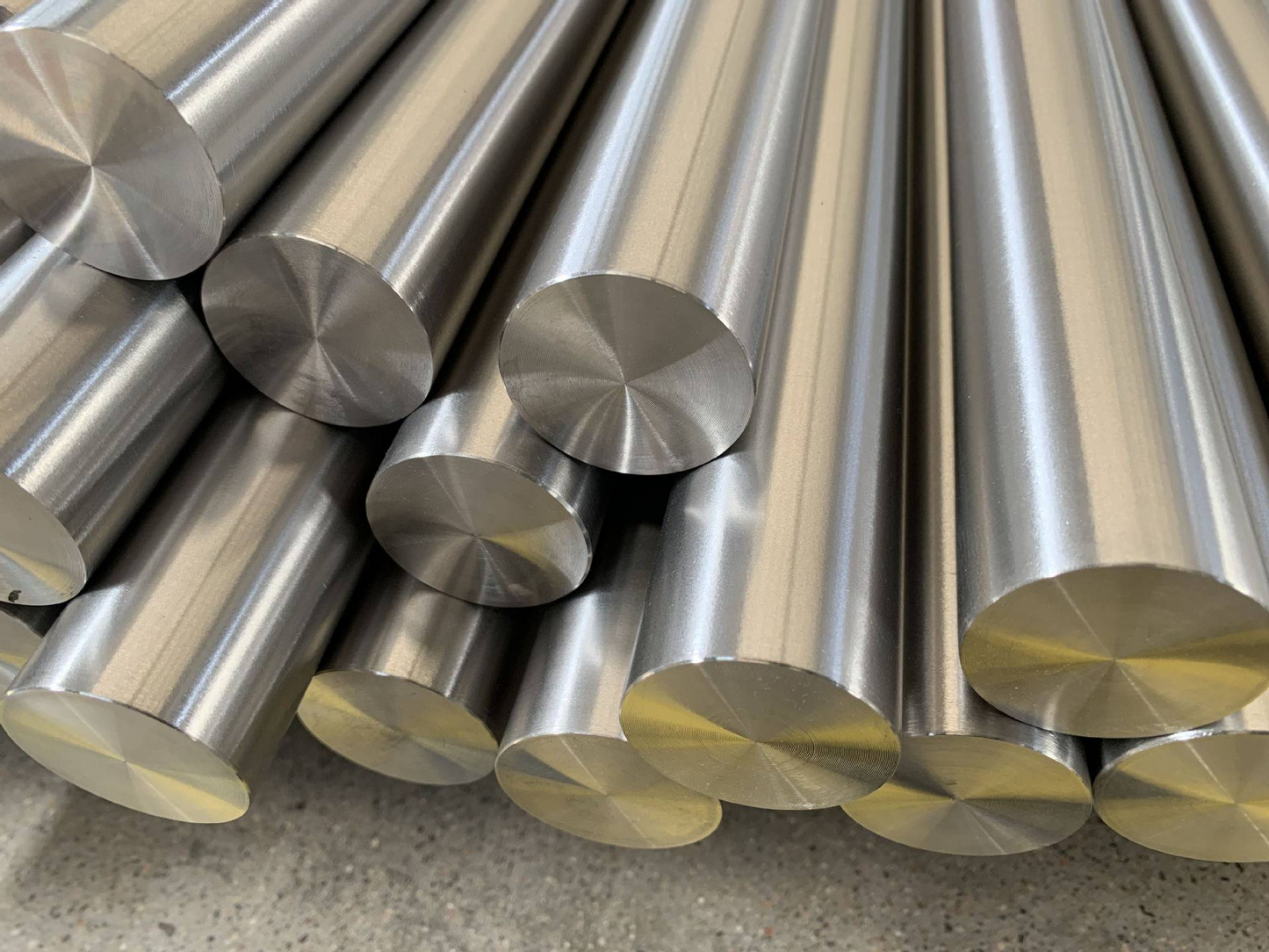

Product Overview

الخصائص المعدنية

يظهر AISI 904L بنية ميكروية أوستنيتية بالكامل في درجة حرارة الغرفة بسبب محتواه العالي من النيكل وتركيب السبائك المتوازن. يُظهر المادة مقاومة استثنائية للتشقق الناتج عن الإجهاد بسبب الكلور ويحافظ على السلامة الهيكلية في البيئات شديدة التآكل. يقلل محتوى الكربون المنخفض (≤ 0.020%) من ترسيب الكربيد، مما يضمن مقاومة مثالية للتآكل حتى في المناطق المتأثرة بالحرارة للهياكل الملحومة.

عملية المعالجة الحرارية

تستخدم MetalZenith عملية تلدين دقيقة في محلول عند 1100-1200°C تليها تبريد سريع بالماء لتحقيق الخصائص الميكانيكية المثلى ومقاومة التآكل. تمنع أفراننا ذات الجو المسيطر أكسدة السطح وتضمن تسخينًا موحدًا في جميع أنحاء مقطع المادة. تزيل معالجة السطح بعد المعالجة الحرارية أي صبغة حرارية وتستعيد الطبقة السلبية.

تميز عملية التصنيع

تبدأ عملية التصنيع المتكاملة لدينا بالذوبان في الفراغ باستخدام مواد خام ممتازة، تليها إعادة الذوبان بالكهرباء لتحسين النظافة. يتم إجراء الدرفلة الساخنة ضمن نطاقات درجات حرارة دقيقة لتحسين بنية الحبوب، بينما تحقق عمليات العمل البارد الخصائص الميكانيكية والدقة الأبعاد المطلوبة. تضمن عمليات معالجة السطح المتقدمة جودة تشطيب فائقة ومقاومة للتآكل.

معايير الجودة والاختبار

تحافظ MetalZenith على الامتثال للمعايير الدولية بما في ذلك ASTM A240 و EN 10088-2 و JIS G4305. تشمل برنامج ضمان الجودة لدينا التحليل الكيميائي عبر طيف الانبعاث الضوئي، والاختبار الميكانيكي وفقًا لمعايير ASTM، واختبار التآكل بين الحبوب (ASTM A262)، والاختبار غير المدمر بما في ذلك الفحص بالموجات فوق الصوتية وفحص الصبغة النافذة. توفر شهادات اختبار المصنع تتبعًا كاملاً والتحقق من المواد.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| الكربون (C) | ≤ 0.020 |

| المنغنيز (Mn) | ≤ 2.00 |

| السيليكون (Si) | ≤ 1.00 |

| الفوسفور (P) | ≤ 0.045 |

| الكبريت (S) | ≤ 0.035 |

| الكروم (Cr) | 19.0 - 23.0 |

| النيكل (Ni) | 23.0 - 28.0 |

| الموليبدينوم (Mo) | 4.0 - 5.0 |

| النحاس (Cu) | 1.0 - 2.0 |

| النيتروجين (N) | ≤ 0.10 |

| الحديد (Fe) | التوازن |

⚙️ Mechanical Properties

| الخاصية | القيمة |

|---|---|

| قوة الشد (Rm) | ≥ 490 MPa |

| قوة الخضوع (Rp0.2) | ≥ 220 MPa |

| التمدد (A5) | ≥ 35% |

| الصلابة (HB) | ≤ 250 |

| الصلابة (HV) | ≤ 270 |

| طاقة الصدمة (KV) عند 20°C | ≥ 100 J |

| معامل يونغ (E) | 200 GPa |

| معامل القص (G) | 81 GPa |

| نسبة بواسون | 0.27 - 0.30 |

| حد التعب (10&sup7; دورة) | 245 MPa |

🔬 Physical Properties

| الخاصية | القيمة |

|---|---|

| الكثافة | 8.0 جرام/سم³ |

| نقطة الانصهار | 1300 - 1390°م |

| التوصيل الحراري عند 100°م | 12 واط/م·ك |

| التمدد الحراري (20-100°م) | 14.2×10-6/ك |

| التمدد الحراري (20-300°م) | 15.1×10-6/ك |

| السعة الحرارية النوعية | 460 جول/كغ·ك |

| المقاومة الكهربائية عند 20°م | 1.05 µΩ·م |

| نفاذية مغناطيسية | 1.02 µr (غير مغناطيسي) |

| الانتشار الحراري | 3.26 مم²/ث |

| درجة حرارة كوري | غير مغناطيسي |

📏 Product Specifications

| المواصفات | الخيارات المتاحة |

|---|---|

| أشكال المنتج | ألواح، صفائح، قضبان، قضبان، أنابيب، مواسير، تشكيلات، فلنجات |

| سمك اللوح | 6 - 200 مم |

| سمك الورقة | 0.5 - 6 مم |

| قطر القضيب | 10 - 300 مم |

| قطر الأنبوب الخارجي | 6 - 610 مم |

| المعايير | ASTM A240, A479, A484, EN 10088-2, JIS G4305, GB/T 24511 |

| تشطيب السطح | 2B, BA, No.4, HL, مرآة, مخلل |

| الت tolerance | ±0.1 مم (سمك), ±3 مم (عرض), ±6 مم (طول) |

| الطول | 2000 - 12000 مم (قياسي), أطوال مخصصة متاحة |

| العرض | 1000 - 2500 مم (قياسي), عرض مخصص متاح |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing AISI 904L

تكنولوجيا الصهر بالفراغ المتقدمة

MetalZenith تستخدم عمليات الصهر بالتحريض الفراغي المتقدم (VIM) وإعادة الصهر بالتيار الكهربائي (ESR) لتحقيق تجانس كيميائي متفوق وتقليل الشوائب في إنتاج AISI 904L. يضمن صهرنا في جو محكم التركيب التركيب المثالي للسبيكة ونقاء استثنائي للمادة.

نظام شامل لمراقبة الجودة

يتميز مختبر الاختبار المتطور لدينا بتحليل طيفي متقدم، ومعدات اختبار ميكانيكية، ومرافق اختبار تآكل متخصصة. يخضع كل دفعة لفحص صارم بما في ذلك الاختبار بالموجات فوق الصوتية، وفحص صبغة الاختراق، واختبار التآكل بين الحبيبات لضمان سلامة المواد.

معالجة مخصصة والإمداد العالمي

تقدم MetalZenith قدرات تخصيص واسعة تشمل التشغيل الدقيق، والمعالجات الحرارية المتخصصة، والأبعاد المخصصة. تضمن شبكة التوزيع العالمية لدينا وإدارة المخزون الاستراتيجية دعم سلسلة التوريد بشكل موثوق مع أوقات تسليم تنافسية للمشاريع في جميع أنحاء العالم.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات