20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

Product Overview

الخصائص المعدنية

يتميز فولاذ SPA H بميكروهيكل حبيبي دقيق من الفريت والبرليت مع ترسيب محكوم لمراحل غنية بالنحاس وكربيدات الكروم. يخلق الإضافة الاستراتيجية للنحاس والكروم والفوسفور والنيكل طبقة باتينا واقية تقلل بشكل كبير من معدلات التآكل الجوي مقارنة بالفولاذ الهيكلي التقليدي. تشكل هذه الآلية الجوية طبقة أكسيد كثيفة وملتصقة تعمل كحاجز ضد المزيد من التآكل.

عملية المعالجة الحرارية

تستخدم MetalZenith الدرفلة المحكومة عند درجات حرارة تتراوح بين 850-950 درجة مئوية تليها تبريد محكوم لتحقيق تحسين مثالي للحبيبات وتوزيع الترسيب. يتم التحكم بدقة في معلمات المعالجة الحرارية الميكانيكية لضمان خصائص ميكانيكية موحدة مع الحفاظ على خصائص ممتازة في قابلية اللحام والتشكيل الضرورية للتطبيقات الهيكلية.

تميز عملية التصنيع

تشمل عملية الإنتاج المتقدمة لدينا الصب المستمر مع التحريك الكهرومغناطيسي، تليها الدرفلة المحكومة مع مراقبة دقيقة لدرجات الحرارة. يضمن نظام مراقبة الجودة في MetalZenith تركيبة كيميائية وخصائص ميكانيكية متسقة من خلال مراقبة العمليات في الوقت الحقيقي وطرق التحكم الإحصائي في العمليات.

اختبارات الجودة المتخصصة

يخضع فولاذ SPA H لاختبارات شاملة بما في ذلك تقييم قابلية اللحام وفقًا لمعايير JIS Z3158، وتقييم أداء التشكيل من خلال اختبارات الانحناء واختبارات السحب العميق، واختبارات قوة التعب تحت ظروف تحميل دورية، واختبارات تآكل جوي متسارعة في بيئات رذاذ الملح والجو الصناعي للتحقق من الأداء على المدى الطويل.

اعتبارات التطبيق الهيكلي

بالنسبة للهياكل البنائية، يوفر فولاذ SPA H نسبة ممتازة من القوة إلى الوزن مع تقليل متطلبات الصيانة. في هندسة الجسور، تلغي الخصائص الجوية الحاجة إلى الطلاءات الواقية في العديد من البيئات. بالنسبة لتصنيع الآلات، يوفر الفولاذ مقاومة فائقة للتعب وثباتًا أبعاديًا. في بناء المركبات، يوفر فرص تقليل الوزن مع الحفاظ على السلامة الهيكلية. تستفيد التطبيقات الهندسية العامة من الجمع بين القوة العالية، وقابلية اللحام الجيدة، والمتانة على المدى الطويل.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| الكربون (C) | ≤ 0.12 |

| المنغنيز (Mn) | 0.20 - 0.50 |

| السيليكون (Si) | 0.25 - 0.75 |

| الفوسفور (P) | 0.07 - 0.15 |

| الكبريت (S) | ≤ 0.035 |

| النحاس (Cu) | 0.25 - 0.40 |

| الكروم (Cr) | 0.30 - 1.25 |

| النيكل (Ni) | ≤ 0.65 |

⚙️ Mechanical Properties

| الخاصية | القيمة |

|---|---|

| قوة العائد (ميغاباسكال) | ≥ 355 |

| قوة الشد (ميغاباسكال) | 490 - 610 |

| التمدد (%) | ≥ 18 |

| طاقة الصدمة عند 0°C (جول) | ≥ 27 |

| الصلابة (HB) | 140 - 200 |

| قوة التعب (ميغاباسكال) | ≥ 160 |

🔬 Physical Properties

| الخاصية | القيمة |

|---|---|

| الكثافة (غ/cm3) | 7.85 |

| نقطة الانصهار (°م) | 1510 - 1540 |

| الموصلية الحرارية (W/m·K) | 50.2 |

| التوسع الحراري (×10??/K) | 12.0 |

| معامل المرونة (GPa) | 206 |

| المقاومة الكهربائية (μΩ·m) | 0.17 |

📏 Product Specifications

| المواصفات | التفاصيل |

|---|---|

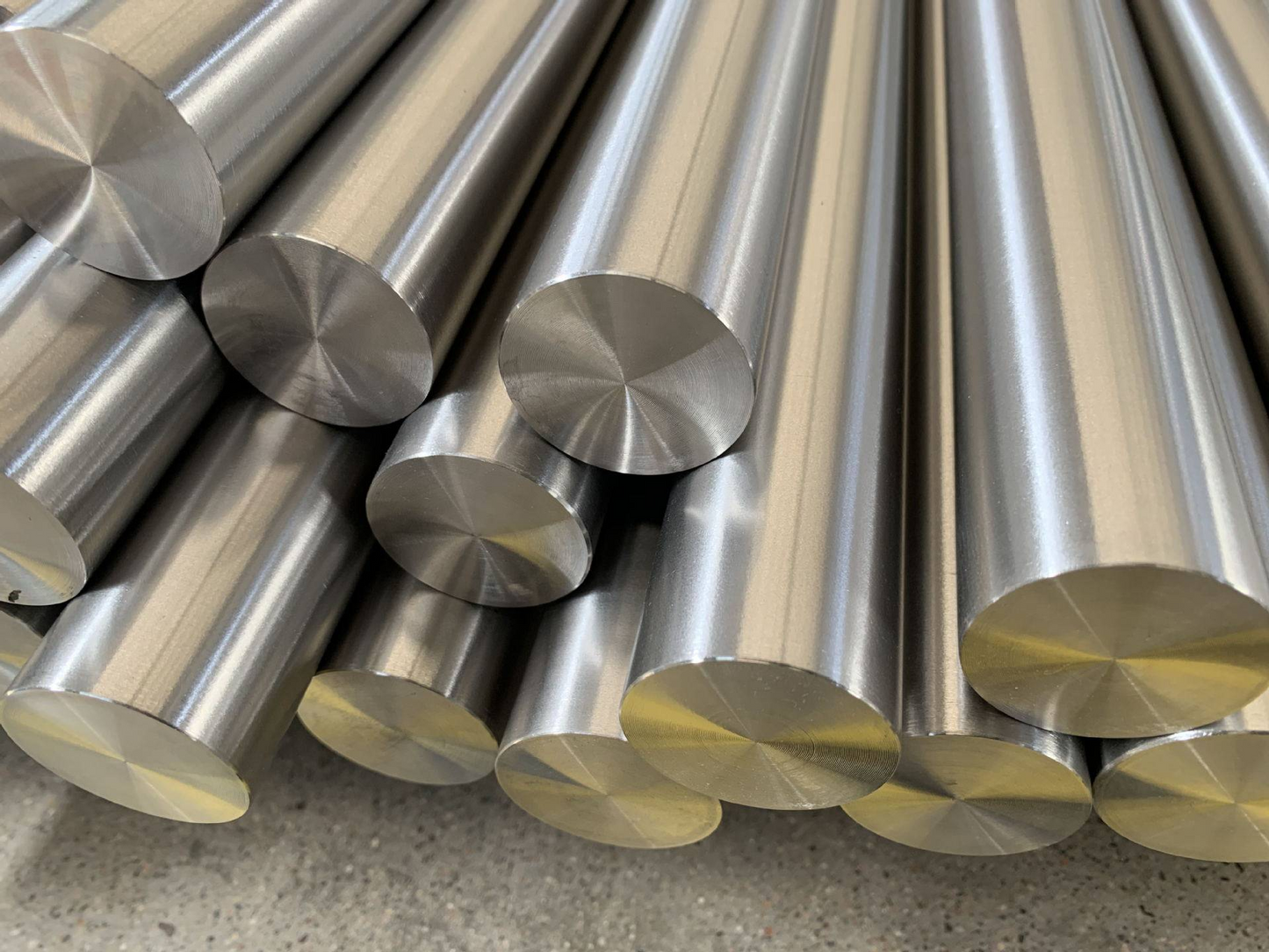

| الأشكال المتاحة | ألواح، صفائح، مقاطع هيكلية، قضبان |

| نطاق السماكة | 4 - 100 مم |

| نطاق العرض | 1000 - 3500 مم |

| نطاق الطول | 6000 - 16000 مم |

| الامتثال للمعايير | JIS G3114، ASTM A588، EN 10155 |

| حالة المعالجة الحرارية | مدرفل على الساخن أو مُعالج |

| حالة السطح | قشور مطحنة، مُنفجر بالرصاص، أو مُخلل |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing فولاذ SPA H

تكنولوجيا الفولاذ المقاوم للتآكل المتقدم

يستخدم MetalZenith التحكم الدقيق في السبائك مع النحاس والكروم والنيكل لتحقيق خصائص الطقس المثلى. تضمن عملية الدرفلة المتحكم بها بنية دقيقة موحدة وتكوين طبقة أكسيد واقية معززة، مما يوفر مقاومة فائقة للتآكل الجوي دون المساس بسلامة الهيكل.

اختبار الأداء الشامل

تخضع حديد H من نوع SPA لاختبارات شاملة بما في ذلك تقييم قابلية اللحام وفقًا لمعيار JIS Z3158، وتقييم أداء التشكيل، واختبار قوة التعب حتى 2×10? دورة، واختبار تآكل الغلاف الجوي المعجل. يضمن ذلك الأداء الأمثل في التطبيقات الهيكلية التي تتطلب متانة طويلة الأمد.

حلول هيكلية مخصصة

MetalZenith تقدم خدمات معالجة مخصصة تشمل القطع الدقيق، والتشكيل، وتحسين معالجة الحرارة. يقدم فريقنا الفني دعمًا شاملاً لتطبيقات التصميم الهيكلي، مما يضمن اختيار المواد المثلى ومعلمات المعالجة لمتطلبات المشروع المحددة.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات