20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

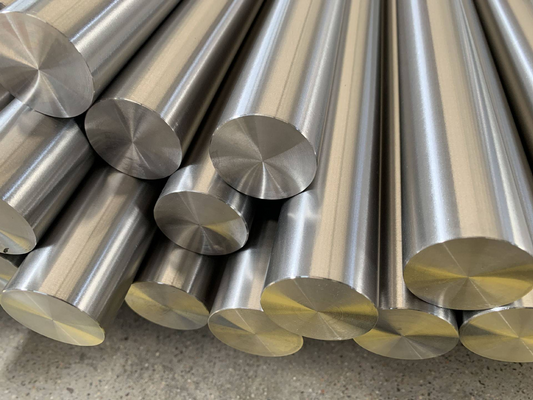

Product Overview

الخصائص المعدنية

EN 16Mo3 هو فولاذ منخفض السبيكة من الكروم والموليبدينوم مصمم خصيصًا لتطبيقات أوعية الضغط عند درجات حرارة مرتفعة. الإضافة المنضبطة للكروم (0.30-0.60%) والموليبدينوم (0.25-0.35%) توفر مقاومة ممتازة للزحف وثبات حراري يصل إلى 500°C. الهيكل الدقيق الحبيبات من الفريت والبيرلايت يضمن الجمع الأمثل بين القوة والصلابة وقابلية اللحام.

عملية المعالجة الحرارية

تستخدم MetalZenith عملية تطبيع منضبطة عند 920-960°C تليها تبريد بالهواء لتحقيق تحسين حبيبات مثالي. يضمن التخمير عند 680-720°C تخفيف الإجهاد وتحسين الصلابة. تحافظ أفراننا التي يتم التحكم فيها بواسطة الكمبيوتر على تجانس درجة الحرارة ضمن ±5°C، مما يضمن خصائص ميكانيكية متسقة في جميع أنحاء مقطع المادة.

عملية التصنيع

تبدأ الإنتاج بصهر فرن القوس الكهربائي باستخدام مواد خام مختارة بعناية. يزيل التفريغ الفراغي الغازات الضارة والشوائب، بينما تضمن المعادن في القادوس التحكم الدقيق في التركيب الكيميائي. ينتج الصب المستمر قضبان عالية الجودة، والتي تخضع للدرفلة المنضبطة مع معايير دقيقة للحرارة والتشوه لتحقيق هيكل دقيق وخصائص ميكانيكية مثالية.

معايير الجودة والامتثال

تتوافق جميع منتجات EN 16Mo3 مع متطلبات معيار EN 10028-2 ويتم تصنيعها تحت نظام إدارة الجودة ISO 9001:2015. يضمن اعتماد PED 2014/68/EU ملاءمتها لتطبيقات معدات الضغط. تشمل الاختبارات الشاملة التحليل الكيميائي بواسطة طيفية الانبعاث الضوئي، والاختبارات الميكانيكية وفقًا لـ EN ISO 6892-1، واختبارات تأثير تشاربي وفقًا لـ EN ISO 148-1. يضمن الاختبار بالموجات فوق الصوتية وفقًا لـ EN 10160 سلامة داخلية.

اعتبارات اللحام

يظهر EN 16Mo3 قابلية لحام ممتازة مع التسخين المسبق المناسب (150-200°C) والمعالجة الحرارية بعد اللحام. تشمل المواد الاستهلاكية الموصى بها للحام أقطاب أو أسلاك مطابقة للتكوين. يجب ألا تتجاوز درجة حرارة التداخل 250°C للحفاظ على الهيكل الدقيق الأمثل. يوصى بإجراء المعالجة الحرارية بعد اللحام عند 680-720°C لتخفيف الإجهاد وتحقيق أداء خدمة مثالي.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| الكربون (C) | ≤ 0.12 |

| المنغنيز (Mn) | 0.40 - 0.90 |

| السيليكون (Si) | ≤ 0.35 |

| الفوسفور (P) | ≤ 0.025 |

| الكبريت (S) | ≤ 0.010 |

| الكروم (Cr) | 0.30 - 0.60 |

| الموليبدينوم (Mo) | 0.25 - 0.35 |

| النيكل (Ni) | ≤ 0.30 |

| الألمنيوم (Al) | ≥ 0.020 |

| النيتروجين (N) | ≤ 0.012 |

| النحاس (Cu) | ≤ 0.30 |

| الفاناديوم (V) | ≤ 0.02 |

⚙️ Mechanical Properties

| الخاصية | القيمة |

|---|---|

| قوة الشد (Rm) | 450 - 600 ميغاباسكال |

| قوة الخضوع (Re) | ≥ 275 ميغاباسكال |

| التمدد (A5) | ≥ 22% |

| طاقة الصدمة (KV) عند 20°C | ≥ 40 جول |

| طاقة الصدمة (KV) عند 0°C | ≥ 27 جول |

| صلابة برينل (HB) | ≤ 190 |

| معامل يونغ | 210 جيجاباسكال |

| نسبة بواسون | 0.30 |

| حد التعب (107 دورة) | 200 ميغاباسكال |

| قوة تمزق الزحف (100,000 ساعة عند 450°C) | 118 ميغاباسكال |

| قوة تمزق الزحف (100,000 ساعة عند 500°C) | 78 ميغاباسكال |

🔬 Physical Properties

| الخاصية | القيمة |

|---|---|

| الكثافة | 7.85 g/cm³ |

| نقطة الانصهار | 1510°C |

| الموصلية الحرارية (20°C) | 42 W/m·K |

| الموصلية الحرارية (400°C) | 35 W/m·K |

| معامل التمدد الحراري (20-100°C) | 11.5×10-6/K |

| معامل التمدد الحراري (20-400°C) | 12.8×10-6/K |

| السعة الحرارية النوعية | 460 J/kg·K |

| المقاومة الكهربائية (20°C) | 0.18 µΩ·m |

| نفاذية مغناطيسية | مغناطيسي حديدي |

| درجة حرارة كوري | 770°C |

| الانتشار الحراري (20°C) | 11.6×10-6 m²/s |

📏 Product Specifications

| المواصفات | الخيارات المتاحة |

|---|---|

| أشكال المنتج | ألواح، صفائح، قضبان، مطروقات، أنابيب، مواسير |

| سمك اللوح | 5 - 250 مم |

| سمك الورقة | 0.5 - 5 مم |

| قطر القضيب | 10 - 300 مم |

| قطر الأنبوب الخارجي | 10 - 600 مم |

| الأبعاد القصوى | 3000 × 12000 مم |

| المعايير | EN 10028-2، ASTM A387 Gr 12، JIS G3103 SBV2 |

| تشطيب السطح | مدرفل على الساخن، مُعالج، مُخلل، مُنفجر بالرصاص |

| فئة التحمل | الفئة A، الفئة B، الفئة C حسب EN 10029 |

| معالجة حرارية | معالجة، معالجة + تلطيف |

| اختبار | شهادة 3.1، شهادة 3.2 حسب EN 10204 |

| متطلبات خاصة | اختبار الاتجاه Z، اختبار HIC، محاكاة PWHT |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing 16Mo3

تكنولوجيا التفريغ المتقدم بالفراغ

MetalZenith تستخدم أنظمة تفريغ الفراغ المتطورة خلال إنتاج الصلب، مما يحقق محتوى منخفض جداً من الكبريت (≤ 0.010%) والفوسفور (≤ 0.025%). تضمن هذه التكنولوجيا المتقدمة نظافة فائقة، وقابلية لحام محسنة، وصلابة تأثير محسنة في فولاذ EN 16Mo3.

تحكم دقيق في معالجة الحرارة

تقدم مرافق المعالجة الحرارية التي تتحكم فيها الكمبيوتر عمليات تطبيع وتقسية دقيقة بدقة حرارة تصل إلى ±5°C. يضمن ذلك هيكل حبيبي مثالي، وخصائص ميكانيكية متسقة، وأداء ممتاز لمقاومة الزحف عبر مقطع المادة.

اختبار شامل وتخصيص

تقدم MetalZenith خدمات تخصيص كاملة بما في ذلك الأبعاد غير القياسية، والتشطيبات السطحية الخاصة، وعلاجات الحرارة المحددة للتطبيق. يوفر مختبر الاختبار الداخلي لدينا شهادة كاملة للمواد مع تحليل كيميائي، واختبارات ميكانيكية، وتقارير فحص بالموجات فوق الصوتية.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات