20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

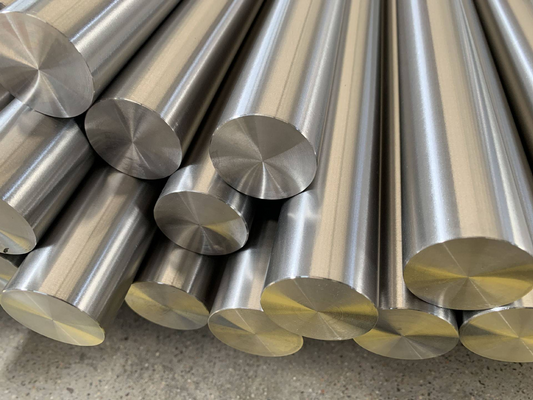

Product Overview

الخصائص المعدنية

P22 هو فولاذ هيكلي منخفض السبيكة من الكروم والموليبدينوم مع بنية ميكروية من الباينيت المعالج حرارياً، تم تحسينها للخدمة في درجات الحرارة العالية. الإضافة المنضبطة للكروم (1.9-2.6%) والموليبدينوم (0.87-1.13%) توفر مقاومة ممتازة للزحف واستقرار حراري، مع الحفاظ على قابلية جيدة للحام والتشكيل للتطبيقات الهيكلية.

عملية المعالجة الحرارية

تستخدم MetalZenith عملية تطبيع منضبطة عند 900-950 درجة مئوية تليها معالجة حرارية عند 700-750 درجة مئوية مع معدلات تبريد دقيقة لتحقيق استقرار ميكروهيكلي مثالي. تضمن هذه العملية معالجة حرارية خصائص ميكانيكية متجانسة ومقاومة زحف محسنة في جميع أنحاء مقطع المادة.

عملية التصنيع

تشمل عملية التصنيع المتقدمة لدينا إزالة الغازات في الفراغ، والدرفلة المنضبطة، والمعالجة الحرارية متعددة المراحل مع مراقبة مستمرة لملفات درجات الحرارة. يضمن نظام مراقبة الجودة في MetalZenith تركيبة كيميائية وخصائص ميكانيكية متسقة من خلال الاختبارات الآلية والتعديلات الفورية في العملية.

اختبارات الجودة المتخصصة

يخضع فولاذ P22 لاختبارات شاملة بما في ذلك اختبار تمزق الزحف عند درجات حرارة الخدمة، واختبار استرخاء الإجهاد، وتقييم التعب الحراري، واختبار مقاومة التشقق الناتج عن الهيدروجين. تتحقق بروتوكولات الاختبار المتخصصة لدينا من الأداء طويل الأمد تحت ظروف تحميل هيكلية عند درجات حرارة مرتفعة.

اعتبارات هندسة التطبيقات

لتطبيقات محطات الطاقة، يوفر P22 مقاومة ممتازة للأكسدة بالبخار واستقراراً أبعادياً. في الهياكل البتروكيميائية، يوفر المادة مقاومة متفوقة لهجوم الهيدروجين والدورات الحرارية. لتطبيقات الآلات الثقيلة، يقدم P22 أداءً متسقاً تحت الضغوط الحرارية والميكانيكية المجمعة، مما يجعله مثالياً للمكونات الهيكلية الحرجة في البيئات الصناعية المت demanding.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| الكربون (C) | 0.05 - 0.15 |

| المنغنيز (Mn) | 0.30 - 0.60 |

| السيليكون (Si) | 0.50 كحد أقصى |

| الفوسفور (P) | ≤ 0.025 |

| الكبريت (S) | ≤ 0.025 |

| الكروم (Cr) | 1.90 - 2.60 |

| الموليبدينوم (Mo) | 0.87 - 1.13 |

⚙️ Mechanical Properties

| الخاصية | القيمة |

|---|---|

| قوة العائد (ميغاباسكال) | ≥ 205 |

| قوة الشد (ميغاباسكال) | 415 - 585 |

| التمدد (%) | ≥ 20 |

| طاقة الصدمة عند 20°C (جول) | ≥ 27 |

| الصلابة (HB) | ≤ 192 |

| قوة تمزق الزحف عند 593°C (ميغاباسكال) | ≥ 69 |

🔬 Physical Properties

| الخاصية | القيمة |

|---|---|

| الكثافة (غ/سم³) | 7.85 |

| نقطة الانصهار (°م) | 1480 - 1520 |

| الموصلية الحرارية (W/m·K) | 42.7 |

| التوسع الحراري (×10??/K) | 11.7 |

| معامل المرونة (GPa) | 200 |

| السعة الحرارية النوعية (J/kg·K) | 460 |

📏 Product Specifications

| المواصفات | التفاصيل |

|---|---|

| الأشكال المتاحة | ألواح، صفائح، قضبان، سبائك، أنابيب |

| نطاق السماكة | 5 - 200 مم |

| نطاق العرض | 1000 - 3000 مم |

| نطاق الطول | 6000 - 12000 مم |

| امتثال المعايير | ASTM A387 Grade 22, ASME SA-387, EN 10028-2 |

| حالة المعالجة الحرارية | مُعالج ومُقسى |

| نطاق درجة حرارة الخدمة | -29°C إلى 593°C |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing فولاذ P22

تكنولوجيا المعالجة الحرارية المتقدمة

تستخدم MetalZenith عمليات تبريد وتحميص دقيقة ومراقبة درجة الحرارة في الوقت الفعلي لتحقيق استقرار ميكروهيكلي مثالي ومقاومة محسّنة للزحف. تضمن معالجة الحرارة المتقدمة لدينا خصائص ميكانيكية متسقة واستقرارًا أبعاديًا عبر سمك المادة للتطبيقات الهيكلية الحرجة.

اختبار شامل لدرجات الحرارة العالية

تجري MetalZenith اختبارات شاملة بما في ذلك اختبار تمزق الزحف، واختبار الشد عند درجات حرارة عالية، واختبار استرخاء الإجهاد، وتقييم التعب الحراري. تضمن بروتوكولات الاختبار المتخصصة لدينا أداءً متفوقًا في التطبيقات الهيكلية عند درجات حرارة مرتفعة مع موثوقية طويلة الأمد مؤكدة.

حلول هيكلية مخصصة

MetalZenith تقدم خدمات معالجة مخصصة شاملة تشمل التشغيل الدقيق، وإعداد اللحام، وجداول المعالجة الحرارية المتخصصة. يقدم فريقنا الفني استشارات خبراء لتحسين تصميم الهياكل واختيار المواد لتلبية متطلبات التطبيقات ذات درجات الحرارة العالية المحددة.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات