20 лет опыта | 1000+ партнеров по брендам | Полная настройка

У нас 20 лет опыта в отрасли, мы сотрудничаем с более чем 1,000 брендами и поддерживаем любые потребности в настройке.

Technical Specifications

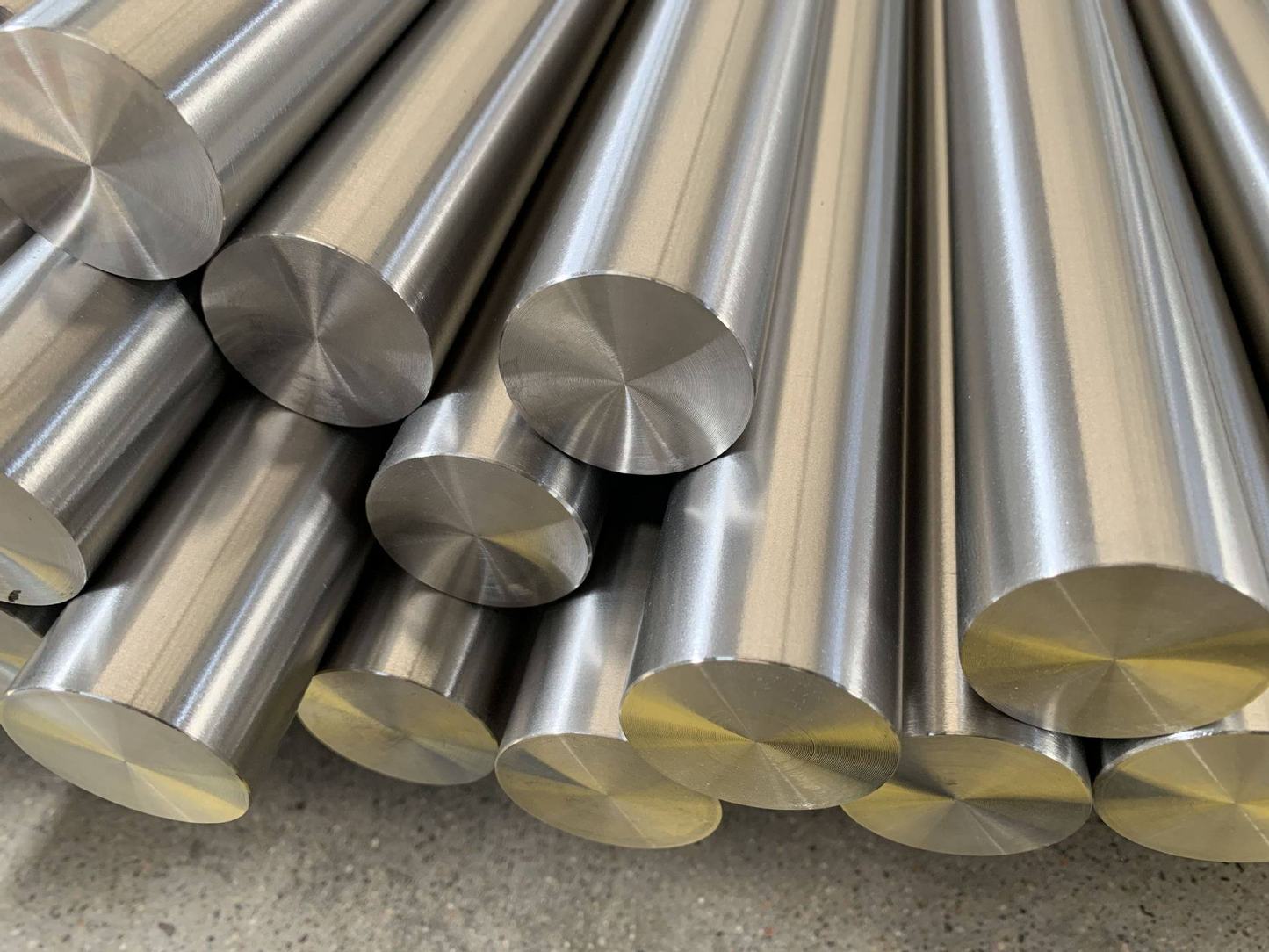

Product Overview

Металлургические характеристики

JIS SUS321 - это аустенитная нержавеющая сталь, стабилизированная добавками титана, которые образуют стабильные карбиды титана (TiC), предотвращающие осаждение карбидов хрома на границах зерен. Этот механизм стабилизации обеспечивает отличную межзерновую коррозионную стойкость и сохраняет механические свойства при повышенных температурах до 900°C. Аустенитная микроструктура обеспечивает превосходную пластичность и прочность по сравнению с ферритными марками.

Процесс термообработки

MetalZenith использует точное растворное отжиг при 1050-1100°C с последующим быстром охлаждением для достижения оптимальной микроструктуры. Стабилизация титаном устраняет необходимость в стабилизирующих термообработках, что делает эту марку подходящей для сварочных приложений без термообработки после сварки. Наши печи с контролируемой атмосферой обеспечивают постоянный размер зерна и предотвращают окисление поверхности во время обработки.

Совершенство производственного процесса

Наш интегрированный производственный процесс начинается с вакуумного индукционного плавления с использованием первоклассных сырьевых материалов, за которым следует электрошлаковая переплавка для повышения чистоты. Горячая прокатка выполняется с использованием компьютеризированных прокатных станов с точным контролем температуры. Процессы холодной прокатки и отжига оптимизированы для достижения целевых механических свойств и качества поверхности. Финальная обработка включает прецизионную резку, отделку поверхности и комплексное тестирование качества.

Стандарты качества и сертификаты

MetalZenith соблюдает международные стандарты, включая JIS G4303, ASTM A240, EN 10088-2 и GB/T 3280. Наша система управления качеством сертифицирована по ISO 9001:2015, AS9100D для аэрокосмических приложений и NADCAP для специальных процессов. Каждая партия проходит комплексное тестирование, включая химический анализ с помощью оптической эмиссионной спектроскопии, механическое тестирование в соответствии со стандартами ASTM, ультразвуковую инспекцию на внутреннюю целостность и измерение размеров с использованием координатных измерительных машин.

🧪 Chemical Composition

| Элемент | Состав (%) |

|---|---|

| Углерод (C) | ≤ 0.08 |

| Кремний (Si) | ≤ 1.00 |

| Марганец (Mn) | ≤ 2.00 |

| Фосфор (P) | ≤ 0.045 |

| Сера (S) | ≤ 0.030 |

| Хром (Cr) | 17.00 - 20.00 |

| Никель (Ni) | 9.00 - 13.00 |

| Титан (Ti) | 4×C - 0.60 |

| Азот (N) | ≤ 0.10 |

| Железо (Fe) | Баланс |

⚙️ Mechanical Properties

| Свойство | Значение |

|---|---|

| Устойчивость к растяжению (Rm) | ≥ 520 MPa |

| Устойчивость к текучести (Rp0.2) | ≥ 205 MPa |

| Удлинение (A50) | ≥ 40% |

| Твердость (HRB) | ≤ 95 |

| Твердость (HV) | ≤ 200 |

| Энергия удара (KV) | ≥ 120 J |

| Модуль Юнга | 200 GPa |

| Предел усталости | 240 MPa |

| Снижение площади | ≥ 60% |

🔬 Physical Properties

| Свойство | Значение |

|---|---|

| Плотность | 7.90 g/cm³ |

| Температура плавления | 1400-1450°C |

| Теплопроводность (20°C) | 16.2 W/m·K |

| Теплопроводность (100°C) | 17.8 W/m·K |

| Тепловое расширение (20-100°C) | 16.6×10-6/K |

| Тепловое расширение (20-300°C) | 17.5×10-6/K |

| Удельная теплоемкость | 500 J/kg·K |

| Электрическое сопротивление (20°C) | 0.72 µΩ·m |

| Магнитная проницаемость | 1.02 µr |

| Коэффициент Пуассона | 0.29 |

📏 Product Specifications

| Спецификация | Доступные варианты |

|---|---|

| Формы продукта | Листы, Пластины, Бруски, Стержни, Трубки, Трубы, Катушки, Ленты |

| Толщина листа | 0.3 - 6.0 мм |

| Толщина пластины | 6.0 - 100 мм |

| Диаметр бруска | 6 - 300 мм |

| Внешний диаметр трубы | 6 - 610 мм |

| Стандарты | JIS G4303, ASTM A240, EN 10088-2, GB/T 3280 |

| Отделка поверхности | 2B, BA, No.4, HL, Зеркало, Кислотная |

| Допуск | ±0.02 - ±0.15 мм (в зависимости от толщины) |

| Длина | 2000 - 12000 мм (настраиваемая) |

| Ширина | 1000 - 2000 мм (листы/пластины) |

Давайте создадим успех для вашего проекта

Профессиональная команда, премиум-продукты, полный сервис - успех вашего проекта является нашей миссией

Our Advantages in Processing JIS SUS321

Совершенная технология вакуумного плавления

MetalZenith использует современные процессы вакуумного индукционного плавления (VIM) и электрошлакового переплавления (ESR) для достижения превосходной химической однородности и ультранизкого содержания включений в JIS SUS321, что обеспечивает исключительную производительность и надежность при высоких температурах.

Комплексная система контроля качества

Наша интегрированная система управления качеством включает в себя анализ химического состава в реальном времени, продвинутые механические испытания, ультразвуковую инспекцию и измерительную проверку на каждом этапе производства, что гарантирует постоянные свойства материалов и полное соответствие международным стандартам.

Глобальное совершенство цепочки поставок

MetalZenith предлагает обширные возможности настройки, включая точную резку, отделку поверхности и услуги термообработки, поддерживаемые нашей мировой сетью распределения, обеспечивающей своевременную доставку и всестороннюю техническую поддержку для всех приложений JIS SUS321.

ВАШ НАДЕЖНЫЙ СТАЛЬ

ПАРТНЕР ПО ПРОИЗВОДСТВУ

Быстрый запрос

Отрасли, которые мы обслуживаем

Профессиональные стальные решения для основных отраслей

Квалификации и сертификаты