20 Anos de Experiência | 1000+ Parceiros de Marca | Personalização Completa

Temos 20 anos de experiência na indústria, fizemos parceria com mais de 1.000 marcas e apoiamos quaisquer necessidades de personalização.

Technical Specifications

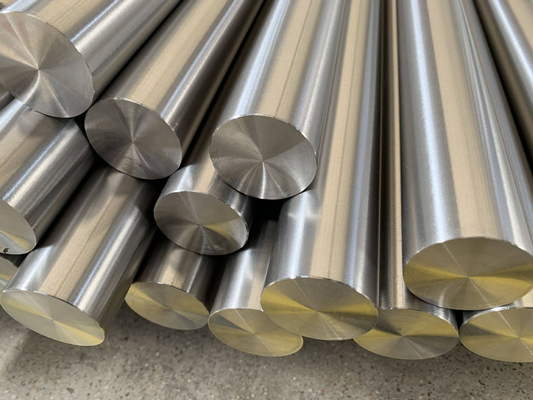

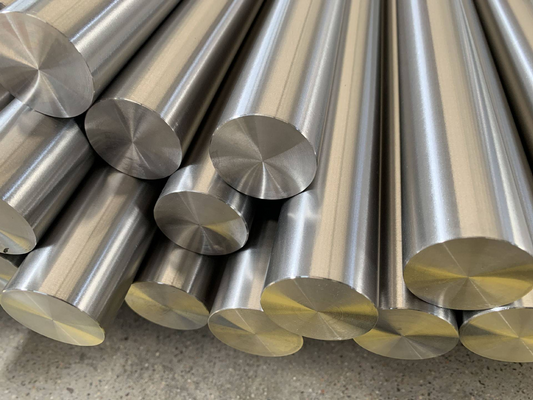

Product Overview

Características Metalúrgicas

UNS N06686 é uma superliga austenítica de níquel-cromo-molibdênio-tungstênio especificamente projetada para resistência à corrosão superior em ambientes altamente agressivos. O desempenho excepcional da liga decorre de seu alto teor de molibdênio e tungstênio, que proporciona resistência notável à corrosão por picotamento, corrosão em fendas e trincas por corrosão sob tensão em ambientes contendo cloreto.

Processo de Tratamento Térmico

A MetalZenith emprega um recozimento de solução preciso a 1150-1175°C seguido de resfriamento rápido para alcançar resistência à corrosão e propriedades mecânicas ideais. O processo de tratamento térmico elimina a precipitação de carbonetos e garante uma microestrutura austenítica homogênea. A desoxidação pós-recozimento remove óxidos de superfície para maximizar o desempenho contra corrosão.

Excelência no Processo de Fabricação

Nosso processo de fabricação começa com fusão por indução a vácuo (VIM) utilizando matérias-primas de alta qualidade, seguido de remeltagem a arco a vácuo (VAR) para maior limpeza e homogeneidade. Operações de trabalho a quente são realizadas dentro de faixas de temperatura controladas para otimizar a estrutura do grão. Ciclos de trabalho a frio e recozimento intermediário garantem precisão dimensional e qualidade de superfície.

Padrões de Qualidade & Testes

Cada lote de produção passa por testes abrangentes, incluindo análise química por espectroscopia de emissão óptica, verificação de propriedades mecânicas, testes de corrosão intergranular conforme ASTM A262 Prática E, e avaliação da temperatura crítica de picotamento. A MetalZenith mantém total rastreabilidade desde as matérias-primas até a inspeção final, garantindo conformidade com NACE MR0175/ISO 15156 para aplicações em serviços ácidos.

Desempenho contra Corrosão

UNS N06686 demonstra resistência excepcional ao ácido sulfúrico, ácido clorídrico, ácido fosfórico e ambientes de ácidos mistos. O alto PREN (Número Equivalente de Resistência ao Picotamento) da liga, de aproximadamente 65, garante desempenho superior em água do mar e soluções contendo cloreto em temperaturas elevadas.

🧪 Chemical Composition

| Elemento | Composição (%) |

|---|---|

| Níquel (Ni) | Equilíbrio |

| Cromo (Cr) | 19.0 - 23.0 |

| Molibdênio (Mo) | 15.0 - 17.0 |

| Tungstênio (W) | 3.0 - 4.4 |

| Ferro (Fe) | ≤ 5.0 |

| Carbono (C) | ≤ 0.010 |

| Manganês (Mn) | ≤ 0.75 |

| Silício (Si) | ≤ 0.08 |

| Fósforo (P) | ≤ 0.040 |

| Enxofre (S) | ≤ 0.010 |

| Alumínio (Al) | ≤ 0.35 |

| Titânio (Ti) | ≤ 0.25 |

⚙️ Mechanical Properties

| Propriedade | Valor |

|---|---|

| Resistência à Tração (Temperatura Ambiente) | ≥ 690 MPa |

| Resistência de Escoamento (Deslocamento de 0,2%) | ≥ 310 MPa |

| Alongamento em 50mm | ≥ 40% |

| Redução de Área | ≥ 40% |

| Dureza (Brinell) | ≤ 250 HB |

| Dureza (Rockwell B) | ≤ 95 HRB |

| Energia de Impacto (Charpy V-notch, Temperatura Ambiente) | ≥ 150 J |

| Resistência à Fadiga (10^7 ciclos) | 275 MPa |

| Módulo de Young | 210 GPa |

| Módulo de Cisalhamento | 81 GPa |

| Razão de Poisson | 0.31 |

🔬 Physical Properties

| Propriedade | Valor |

|---|---|

| Densidade | 8.25 g/cm³ |

| Faixa de Ponto de Fusão | 1325-1370°C |

| Condutividade Térmica (100°C) | 9.8 W/m·K |

| Condutividade Térmica (500°C) | 16.8 W/m·K |

| Expansão Térmica (20-100°C) | 12.4×10-6/K |

| Expansão Térmica (20-500°C) | 13.9×10-6/K |

| Capacidade Calorífica Específica | 420 J/kg·K |

| Resistividade Elétrica (20°C) | 1.24 µΩ·m |

| Permeabilidade Magnética | 1.002 (Essencialmente Não Magnético) |

| Temperatura de Curie | Não Aplicável |

📏 Product Specifications

| Especificação | Opções Disponíveis |

|---|---|

| Formas de Produto | Barra Redonda, Barra Chata, Placa, Folha, Fita, Tubo, Cano, Fio, Estoque de Forjamento |

| Diâmetro da Barra Redonda | 6mm - 300mm |

| Espessura da Placa | 3mm - 100mm |

| Espessura da Folha | 0.5mm - 6mm |

| Diâmetro Externo do Tubo | 6mm - 219mm |

| Conformidade com Normas | ASTM B574, ASME SB-574, UNS N06686, DIN 2.4606 |

| Acabamento de Superfície | Laminado a Quente, Laminado a Frio, Recozido Brilhante, Desincrustado, Polido |

| Tolerância Dimensional | Padrão ASTM ou Requisitos Personalizados |

| Opções de Comprimento | Comprimentos Padrão ou Cortado sob Medida |

| Condição de Tratamento Térmico | Recozido em Solução e Desincrustado |

Vamos Criar Sucesso para o Seu Projeto

Equipe Profissional, Produtos Premium, Serviço Completo - O Sucesso do Seu Projeto é Nossa Missão

Our Advantages in Processing UNS N06686

Tecnologia Avançada de Fusão a Vácuo

MetalZenith emprega processos de fusão por indução a vácuo (VIM) e remeltagem por arco a vácuo (VAR) de última geração para produzir UNS N06686 com superior homogeneidade química, mínimas inclusões e qualidade metalúrgica excepcional que supera os padrões da indústria.

Sistema Abrangente de Controle de Qualidade

Nosso sistema integrado de gestão da qualidade apresenta análise espectroscópica avançada, laboratórios de testes mecânicos e instalações de testes de corrosão. Cada lote recebe certificação completa de material com total rastreabilidade e conformidade com ASTM B574, ASME SB-574 e normas internacionais.

Processamento Personalizado e Suprimento Global

MetalZenith oferece amplas capacidades de personalização, incluindo usinagem de precisão, otimização de tratamento térmico e acabamentos de superfície especializados. Nossa rede de distribuição global garante a entrega confiável de produtos UNS N06686 em todo o mundo, com suporte técnico abrangente e consultoria de engenharia.

SEU CONFIÁVEL AÇO

PARCEIRO DE MANUFATURA

Quick Inquiry

Indústrias que Atendemos

Soluções de aço profissionais em grandes indústrias

Qualificações e Certificações