20 Anos de Experiência | 1000+ Parceiros de Marca | Personalização Completa

Temos 20 anos de experiência na indústria, fizemos parceria com mais de 1.000 marcas e apoiamos quaisquer necessidades de personalização.

Technical Specifications

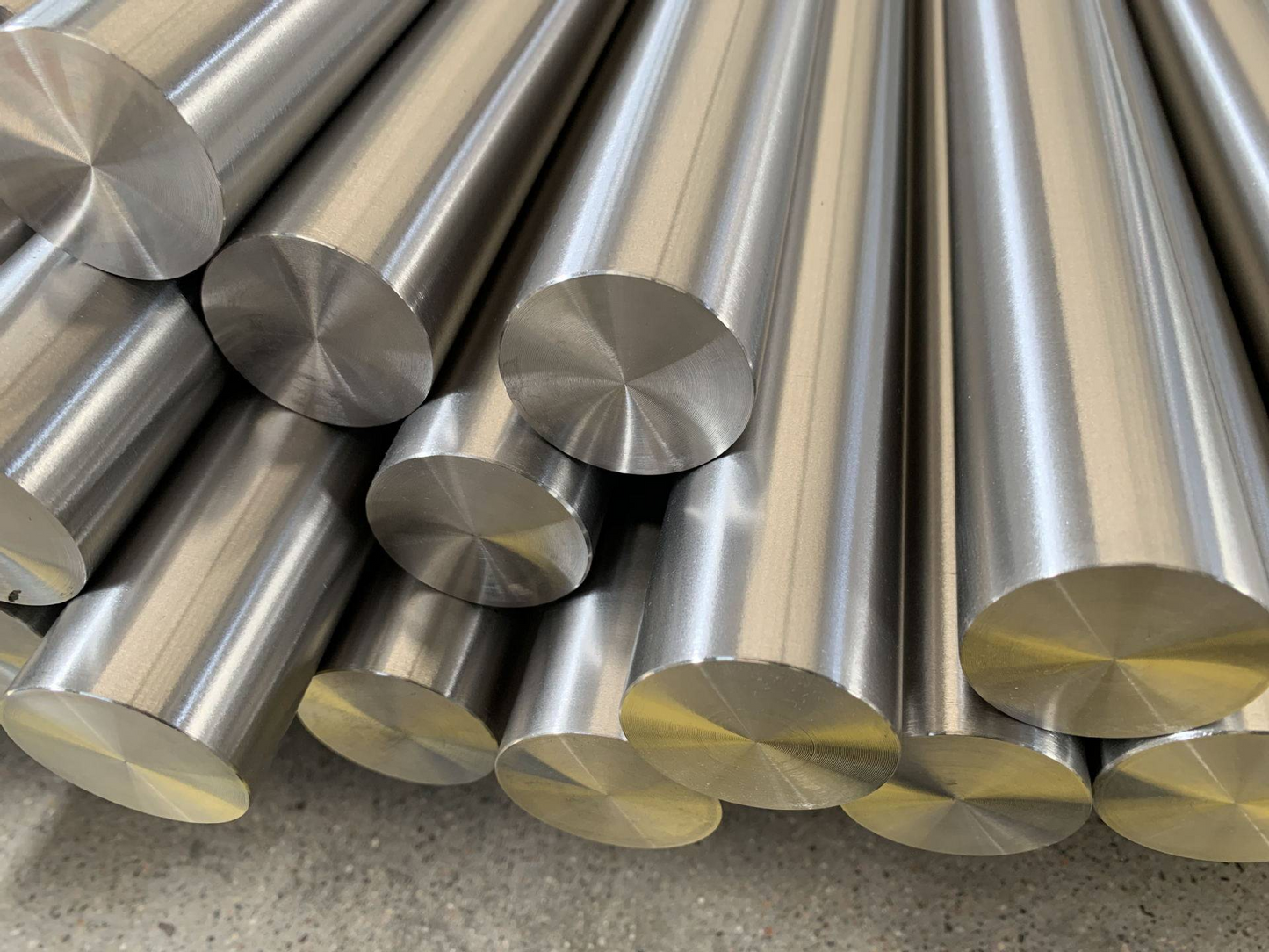

Product Overview

Características Metalúrgicas

O aço ferramenta T1 exibe uma microestrutura martensítica após a têmpera com carbonetos finos e uniformemente distribuídos que proporcionam resistência ao desgaste excepcional. O alto teor de carbono permite o máximo potencial de dureza, enquanto adições controladas de tungstênio e vanádio melhoram a estabilidade dos carbonetos e o refinamento do grão. O processo de fusão de precisão da MetalZenith garante mínima segregação e distribuição ideal de carbonetos.

Processo de Tratamento Térmico

A MetalZenith emprega têmpera em atmosfera controlada a 760-790°C seguida de resfriamento em água para alcançar a transformação martensítica ideal. O revenimento a 150-200°C proporciona o equilíbrio ideal entre dureza e tenacidade. Nossa opção de tratamento criogênico reduz ainda mais o teor de austenita retida abaixo de 2% para máxima estabilidade dimensional.

Processo de Fabricação Avançado

Nossa produção de T1 utiliza fusão por indução a vácuo seguida de remeltagem por eletroescória para alcançar limpeza e homogeneidade excepcionais. A forjamento controlado com monitoramento preciso de temperatura garante fluxo de grão e distribuição de carbonetos ideais. Ciclos de recozimento avançados proporcionam dureza uniforme e excelente usinabilidade na condição recozida.

Testes de Qualidade Especializados

A MetalZenith realiza mapeamento abrangente da distribuição de dureza Rockwell em seções transversais de ferramentas, análise de difração de raios X para quantificação de austenita retida (tipicamente <3%), avaliação metalográfica detalhada do tamanho e distribuição de carbonetos, e testes de fadiga em feixe rotativo para validar o desempenho sob condições de carga cíclica típicas em aplicações de ferramentas.

Considerações Específicas de Aplicação

Para aplicações de ferramentas de corte, o T1 proporciona excelente retenção de aresta e resistência ao desgaste. Na fabricação de matrizes e moldes, o aço oferece superior estabilidade dimensional e capacidade de acabamento de superfície. Para aplicações de rolamentos, a estrutura de carboneto fino garante excelente resistência à fadiga por contato rolante. Em máquinas de precisão, o T1 oferece precisão dimensional excepcional e qualidade de superfície. Componentes automotivos se beneficiam da alta resistência e resistência ao desgaste do aço em condições operacionais exigentes.

🧪 Chemical Composition

| Elemento | Composição (%) |

|---|---|

| Carbono (C) | 0.60 - 0.75 |

| Manganês (Mn) | 0.10 - 0.40 |

| Silício (Si) | 0.10 - 0.40 |

| Fósforo (P) | ≤ 0.030 |

| Enxofre (S) | ≤ 0.030 |

| Cromo (Cr) | 0.10 - 0.30 |

| Tungstênio (W) | 0.50 - 1.00 |

| Vanádio (V) | 0.10 - 0.30 |

⚙️ Mechanical Properties

| Propriedade | Valor |

|---|---|

| Dureza (HRC) | 60 - 65 |

| Resistência à Compressão (MPa) | ≥ 2800 |

| Tenacidade ao Impacto (J) | 15 - 25 |

| Índice de Resistência ao Desgaste | 8.5 - 9.2 |

| Hardenabilidade (mm) | 25 - 40 |

| Resistência à Fadiga (MPa) | ≥ 450 |

🔬 Physical Properties

| Propriedade | Valor |

|---|---|

| Densidade (g/cm3) | 7.84 |

| Ponto de Fusão (°C) | 1460 - 1500 |

| Condutividade Térmica (W/m·K) | 42.7 |

| Expansão Térmica (×10??/K) | 11.9 |

| Módulo de Elasticidade (GPa) | 210 |

| Razão de Poisson | 0.27 - 0.30 |

📏 Product Specifications

| Especificação | Detalhes |

|---|---|

| Formas Disponíveis | Redondas, Planas, Quadradas, Blank de Ferramenta, Moído de Precisão |

| Faixa de Diâmetro | 3 - 300mm |

| Faixa de Espessura | 1 - 150mm |

| Faixa de Comprimento | 100 - 6000mm |

| Conformidade com Normas | ASTM A681, DIN 1.1545, JIS SKS3 |

| Condição de Tratamento Térmico | Recozido, Endurecido & Temperado, Aliviado de Tensão |

| Acabamento de Superfície | Laminado a Quente, Estirado a Frio, Moído de Precisão |

Vamos Criar Sucesso para o Seu Projeto

Equipe Profissional, Produtos Premium, Serviço Completo - O Sucesso do Seu Projeto é Nossa Missão

Our Advantages in Processing Aço Ferramenta T1

Tecnologia de Fusão a Vácuo de Precisão

MetalZenith utiliza fusão por indução a vácuo avançada seguida de remeltagem por eletroslag para alcançar uma homogeneidade química excepcional e minimizar inclusões. Nosso processo de forjamento controlado com monitoramento preciso da temperatura garante uma estrutura de grão ideal e distribuição de carbonetos em toda a seção transversal do material.

Teste Abrangente de Aço Ferramenta

Nossos protocolos de teste especializados incluem mapeamento da distribuição de dureza Rockwell, análise do conteúdo de austenita retida usando difração de raios X, avaliação do tamanho e distribuição de carbonetos por meio de análise metalográfica e testes de fadiga com feixe rotativo para garantir desempenho consistente em aplicações de ferramentas exigentes.

Soluções Personalizadas de Tratamento Térmico

MetalZenith oferece serviços de tratamento térmico sob medida, incluindo endurecimento em atmosfera controlada, têmpera de precisão e tratamento criogênico. Nossos engenheiros metalúrgicos fornecem suporte técnico para otimizar perfis de dureza e estabilidade dimensional com base em requisitos específicos de ferramentas.

SEU CONFIÁVEL AÇO

PARCEIRO DE MANUFATURA

Quick Inquiry

Indústrias que Atendemos

Soluções de aço profissionais em grandes indústrias

Qualificações e Certificações