20 Anos de Experiência | 1000+ Parceiros de Marca | Personalização Completa

Temos 20 anos de experiência na indústria, fizemos parceria com mais de 1.000 marcas e apoiamos quaisquer necessidades de personalização.

Technical Specifications

Product Overview

Características Metalúrgicas

EN 1.4541 é um aço inoxidável austenítico estabilizado com titânio para prevenir corrosão intergranular na faixa de temperatura de 425-815°C. O teor de titânio forma carbonetos estáveis (TiC) que impedem a precipitação de carbonetos de cromo nas fronteiras dos grãos, mantendo a resistência à corrosão mesmo após soldagem ou exposição a altas temperaturas. A microestrutura austenítica proporciona excelente ductilidade e tenacidade em uma ampla faixa de temperatura.

Processo de Tratamento Térmico

MetalZenith emprega recozimento em atmosfera controlada a 1050-1100°C seguido de resfriamento rápido para alcançar propriedades ótimas. Nossas instalações avançadas de tratamento térmico apresentam controle de temperatura preciso (±5°C) e sistemas de atmosfera protetora para prevenir oxidação e descarbonização. Alívio de tensões pós-recozimento a 850-900°C pode ser aplicado para aplicações específicas que requerem estabilidade dimensional.

Excelência no Processo de Fabricação

Nosso processo de produção integrado começa com fusão em forno de arco elétrico seguida de refino AOD para controle preciso da composição. A fundição contínua garante estrutura homogênea, enquanto nossos laminadores a quente de múltiplos estágios com controle de processo computadorizado oferecem propriedades mecânicas consistentes. As capacidades de trabalho a frio incluem laminação de precisão, trefilação e operações de conformação com ciclos de recozimento intermediários para manter a microestrutura ideal.

Padrões de Qualidade & Testes

Todos os produtos EN 1.4541 passam por testes abrangentes, incluindo espectroscopia de emissão óptica para análise química, testes de tração conforme ASTM A370, testes de corrosão intergranular conforme ASTM A262 Prática A, e inspeção ultrassônica para integridade interna. Nosso sistema de gestão da qualidade garante conformidade com os requisitos de certificação EN 10204 3.1, proporcionando rastreabilidade completa do material desde as matérias-primas até os produtos acabados. O exame metalográfico avançado verifica o tamanho dos grãos, o teor de inclusões e a distribuição de fases de acordo com os padrões ASTM E112 e E45.

🧪 Chemical Composition

| Elemento | Composição (%) |

|---|---|

| Carbono (C) | ≤ 0.08 |

| Silício (Si) | ≤ 1.00 |

| Manganês (Mn) | ≤ 2.00 |

| Fósforo (P) | ≤ 0.045 |

| Enxofre (S) | ≤ 0.030 |

| Cromo (Cr) | 17.0 - 19.0 |

| Níquel (Ni) | 9.0 - 12.0 |

| Titânio (Ti) | 5×C - 0.70 |

| Nitrogênio (N) | ≤ 0.10 |

| Ferro (Fe) | Equilíbrio |

⚙️ Mechanical Properties

| Propriedade | Valor |

|---|---|

| Resistência à Tração (Rm) | 520 - 720 MPa |

| Resistência de Escoamento (Rp0.2) | ≥ 205 MPa |

| Alongamento (A5) | ≥ 40% |

| Dureza (HB) | ≤ 215 |

| Energia de Impacto (KV) | ≥ 60 J (a 20°C) |

| Módulo de Young | 200 GPa |

| Limite de Fadiga | 240 MPa (107 ciclos) |

| Razão de Poisson | 0.30 |

🔬 Physical Properties

| Propriedade | Valor |

|---|---|

| Densidade | 7.90 g/cm³ |

| Ponto de Fusão | 1400 - 1425°C |

| Condutividade Térmica (20°C) | 16.2 W/m·K |

| Expansão Térmica (20-100°C) | 16.6×10-6/K |

| Capacidade Calorífica Específica | 500 J/kg·K |

| Resistividade Elétrica (20°C) | 0.72 µΩ·m |

| Permeabilidade Magnética | 1.02 (Não magnético) |

| Difusividade Térmica | 4.1×10-6 m²/s |

📏 Product Specifications

| Especificação | Opções Disponíveis |

|---|---|

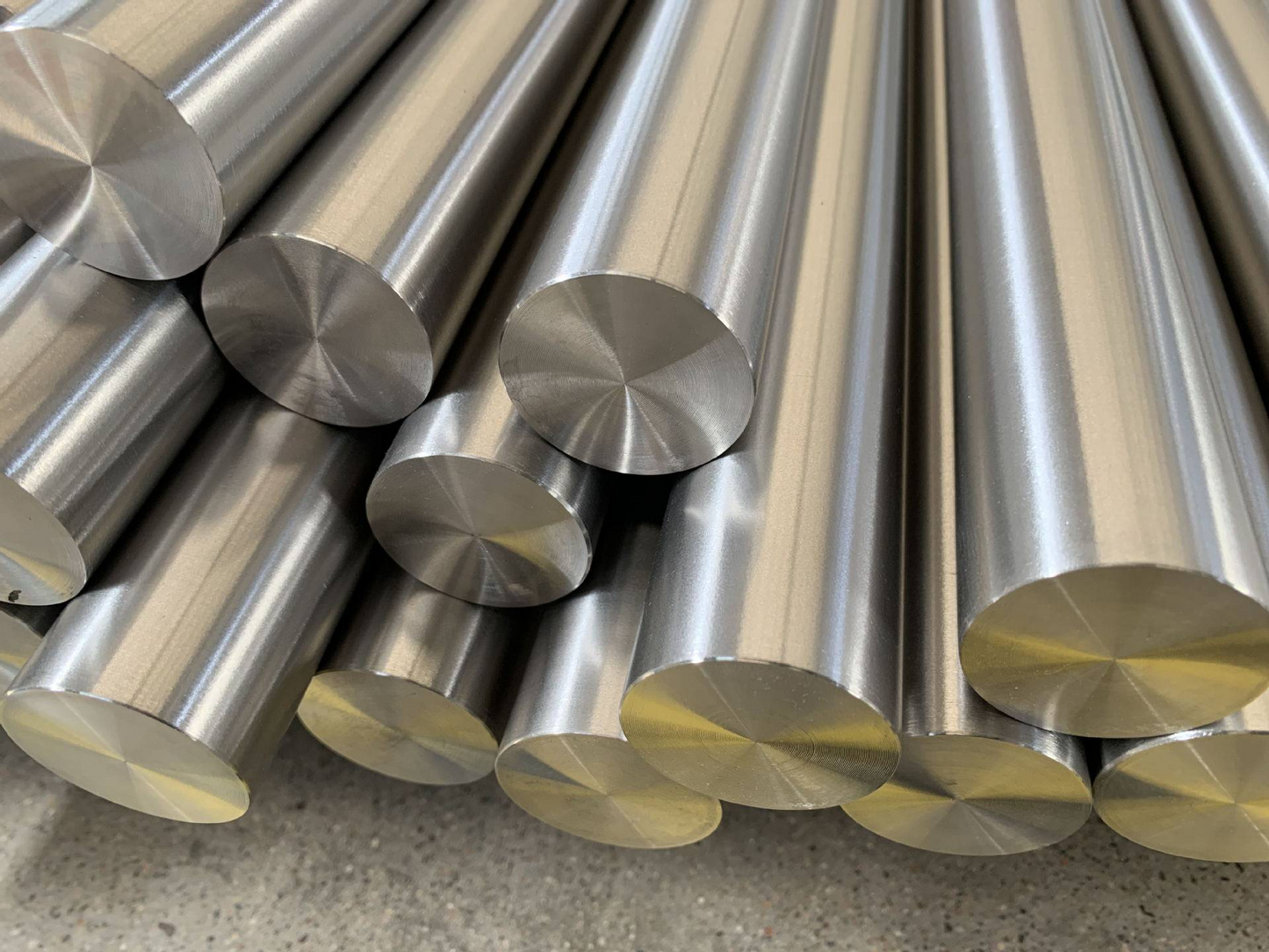

| Formas de Produto | Barras redondas, barras planas, chapas, placas, tubos, canos, fios, forjados |

| Diâmetro da Barra Redonda | 6mm - 300mm |

| Dimensões da Barra Plana | 10×3mm - 150×50mm |

| Espessura da Chapa | 0.4mm - 6.0mm |

| Espessura da Placa | 6mm - 100mm |

| Diâmetro Externo do Tubo | 6mm - 219mm |

| Normas | EN 10088, ASTM A240, A276, A312, JIS G4303, G4304 |

| Acabamento de Superfície | Laminado a quente, laminado a frio, brilhante recozido, decapado, polido |

| Classe de Tolerância | h9, h11 (barras), ±0.1mm (chapas/placas) |

Vamos Criar Sucesso para o Seu Projeto

Equipe Profissional, Produtos Premium, Serviço Completo - O Sucesso do Seu Projeto é Nossa Missão

Our Advantages in Processing 1.4541

Tecnologia Avançada de Derretimento a Vácuo

MetalZenith emprega processos de fusão por indução a vácuo (VIM) e remeltagem por eletroescória (ESR) de última geração para produzir EN 1.4541 com pureza e homogeneidade excepcionais. Nossa tecnologia avançada de fusão garante controle preciso da estabilização do titânio, resultando em propriedades superiores em altas temperaturas e resistência aprimorada à corrosão intergranular.

Sistema Abrangente de Controle de Qualidade

Nosso sistema integrado de gestão da qualidade apresenta análise espectroscópica avançada, testes mecânicos automatizados e monitoramento de processos em tempo real. Cada lote de EN 1.4541 passa por testes rigorosos, incluindo verificação da composição química, validação das propriedades mecânicas e exame microestrutural para garantir qualidade consistente e conformidade com padrões internacionais.

Processamento Personalizado e Cadeia de Suprimentos Global

MetalZenith oferece amplas capacidades de personalização, incluindo usinagem de precisão, tratamentos térmicos especializados e dimensões personalizadas. Nossa rede global de cadeia de suprimentos com armazéns estrategicamente localizados garante entrega rápida em todo o mundo, enquanto nossa equipe de suporte técnico fornece assistência de engenharia para requisitos específicos de aplicação e otimização de materiais.

SEU CONFIÁVEL AÇO

PARCEIRO DE MANUFATURA

Quick Inquiry

Indústrias que Atendemos

Soluções de aço profissionais em grandes indústrias

Qualificações e Certificações