20 Anos de Experiência | 1000+ Parceiros de Marca | Personalização Completa

Temos 20 anos de experiência na indústria, fizemos parceria com mais de 1.000 marcas e apoiamos quaisquer necessidades de personalização.

Technical Specifications

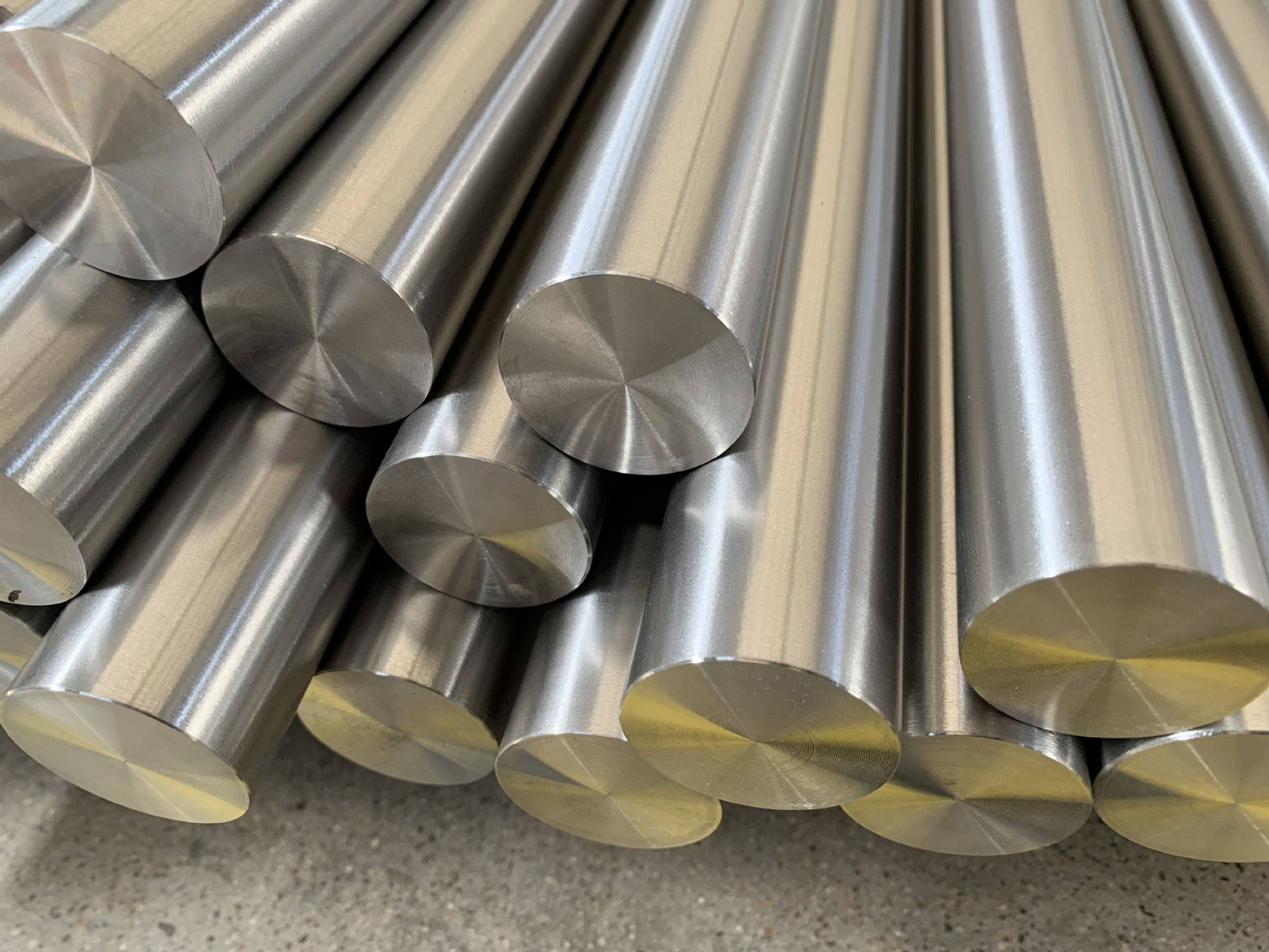

Product Overview

Características Metalúrgicas

EN 1.4307 é um aço inoxidável austenítico com uma estrutura cristalina cúbica de face centrada que proporciona excelente ductilidade e tenacidade. O baixo teor de carbono (≤ 0.030%) minimiza a precipitação de carbonetos, garantindo resistência superior à corrosão intergranular e soldabilidade. A composição equilibrada de cromo-níquel cria uma matriz austenítica estável com resistência à corrosão excepcional em vários ambientes.

Processo de Tratamento Térmico

A MetalZenith aplica recozimento em solução a 1050-1100°C seguido de resfriamento rápido para alcançar a microestrutura ideal. Este tratamento térmico dissolve carbonetos e garante uma estrutura de grão austenítico uniforme. O trabalho a frio pode aumentar significativamente a resistência, mantendo uma excelente conformabilidade. O recozimento de alívio de tensões a 400-450°C pode ser aplicado para estabilidade dimensional em aplicações de precisão.

Processo de Fabricação

Nosso processo de produção começa com a fusão em forno de arco elétrico seguida de descarbonização a oxigênio argônio (AOD) para controle preciso da composição. A laminação a quente a 1150-950°C desenvolve as propriedades mecânicas desejadas, enquanto a laminação a frio alcança as dimensões finais e a qualidade da superfície. Os avançados processos de decapagem e passivação da MetalZenith garantem resistência à corrosão ideal e acabamento superficial.

Padrões de Qualidade & Testes

Todos os produtos EN 1.4307 passam por testes abrangentes, incluindo análise química por espectroscopia de emissão óptica, verificação de propriedades mecânicas através de testes de tração e dureza, e avaliação da resistência à corrosão. Métodos de teste não destrutivos, incluindo inspeção ultrassônica e teste de corrente de Foucault, garantem qualidade interna. A MetalZenith mantém total rastreabilidade desde as matérias-primas até a inspeção final, fornecendo documentação completa e conformidade com certificações.

🧪 Chemical Composition

| Elemento | Composição (%) |

|---|---|

| Carbono (C) | ≤ 0.030 |

| Silício (Si) | ≤ 1.00 |

| Manganês (Mn) | ≤ 2.00 |

| Fósforo (P) | ≤ 0.045 |

| Enxofre (S) | ≤ 0.030 |

| Cromo (Cr) | 17.50 - 19.50 |

| Níquel (Ni) | 8.00 - 10.50 |

| Nitrogênio (N) | ≤ 0.10 |

| Ferro (Fe) | Equilíbrio |

⚙️ Mechanical Properties

| Propriedade | Valor |

|---|---|

| Resistência à Tração (Rm) | 520 - 670 MPa |

| Resistência de Escoamento (Rp0.2) | ≥ 205 MPa |

| Alongamento (A5) | ≥ 45% |

| Dureza (HRB) | ≤ 92 |

| Dureza (HV) | ≤ 200 |

| Energia de Impacto (KV) | ≥ 120 J (a 20°C) |

| Módulo de Young | 200 GPa |

| Limite de Fadiga | 245 MPa (10&sup7; ciclos) |

🔬 Physical Properties

| Propriedade | Valor |

|---|---|

| Densidade | 8.00 g/cm³ |

| Ponto de Fusão | 1400 - 1450°C |

| Coeficiente de Expansão Térmica (20-100°C) | 16.0×10-6/K |

| Coeficiente de Expansão Térmica (20-300°C) | 17.0×10-6/K |

| Condutividade Térmica (20°C) | 15 W/m·K |

| Capacidade Calorífica Específica | 500 J/kg·K |

| Resistividade Elétrica (20°C) | 0.73 µΩ·m |

| Permeabilidade Magnética | 1.02 µr (máx) |

| Razão de Poisson | 0.27 - 0.30 |

📏 Product Specifications

| Especificação | Opções Disponíveis |

|---|---|

| Formas de Produto | Folhas, Placas, Barras, Varas, Tubos, Canos, Bobinas, Faixas |

| Espessura da Folha | 0.3 - 6.0 mm |

| Espessura da Placa | 6.0 - 100 mm |

| Diâmetro da Barra | 6 - 300 mm |

| Diâmetro Externo do Tubo | 6 - 219 mm |

| Acabamentos de Superfície | 2B, BA, No.4, HL, Espelho, Desengordurado |

| Conformidade com Normas | EN 10088, ASTM A240/A276/A312, JIS G4303/G4304 |

| Tolerância Dimensional | ±0.1 mm (espessura), ±1.0 mm (largura/comprimento) |

| Condição da Borda | Borda de Moinho, Borda Cortada, Borda Serrada |

Vamos Criar Sucesso para o Seu Projeto

Equipe Profissional, Produtos Premium, Serviço Completo - O Sucesso do Seu Projeto é Nossa Missão

Our Advantages in Processing 1.4307

Tecnologia Avançada de Derretimento a Vácuo

MetalZenith emprega processos de fusão por indução a vácuo (VIM) e remeltagem por eletroescória (ESR) de última geração para produzir EN 1.4307 com pureza e homogeneidade excepcionais. Nossas técnicas de refino avançadas garantem controle preciso do teor de carbono abaixo de 0,030%, proporcionando soldabilidade e resistência à corrosão superiores em comparação com métodos de produção padrão.

Sistema Abrangente de Controle de Qualidade

Nosso sistema integrado de gestão da qualidade apresenta monitoramento em tempo real da composição química, inspeção dimensional automatizada e capacidades avançadas de testes não destrutivos. O laboratório certificado da MetalZenith realiza a verificação completa das propriedades mecânicas, garantindo que cada lote de EN 1.4307 atenda ou exceda os padrões internacionais com documentação completa de rastreabilidade do material.

Personalização Flexível & Suprimento Global

MetalZenith oferece amplas opções de personalização para EN 1.4307, incluindo acabamentos de superfície especializados, tolerâncias de precisão e dimensões personalizadas. Nossa rede global de cadeia de suprimentos garante entrega confiável em todo o mundo, enquanto nossa equipe técnica de engenharia fornece otimização de material específica para a aplicação e suporte técnico abrangente durante todo o ciclo de vida do projeto.

SEU CONFIÁVEL AÇO

PARCEIRO DE MANUFATURA

Quick Inquiry

Indústrias que Atendemos

Soluções de aço profissionais em grandes indústrias

Qualificações e Certificações