20 Anos de Experiência | 1000+ Parceiros de Marca | Personalização Completa

Temos 20 anos de experiência na indústria, fizemos parceria com mais de 1.000 marcas e apoiamos quaisquer necessidades de personalização.

Technical Specifications

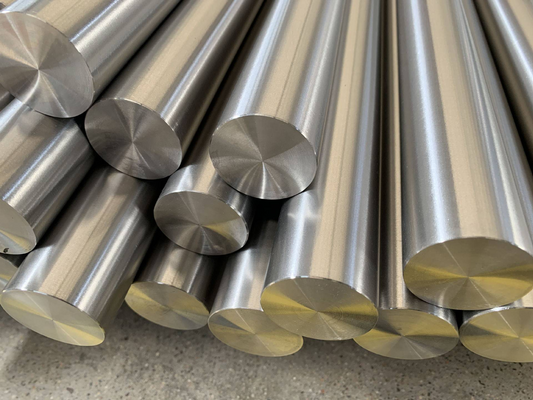

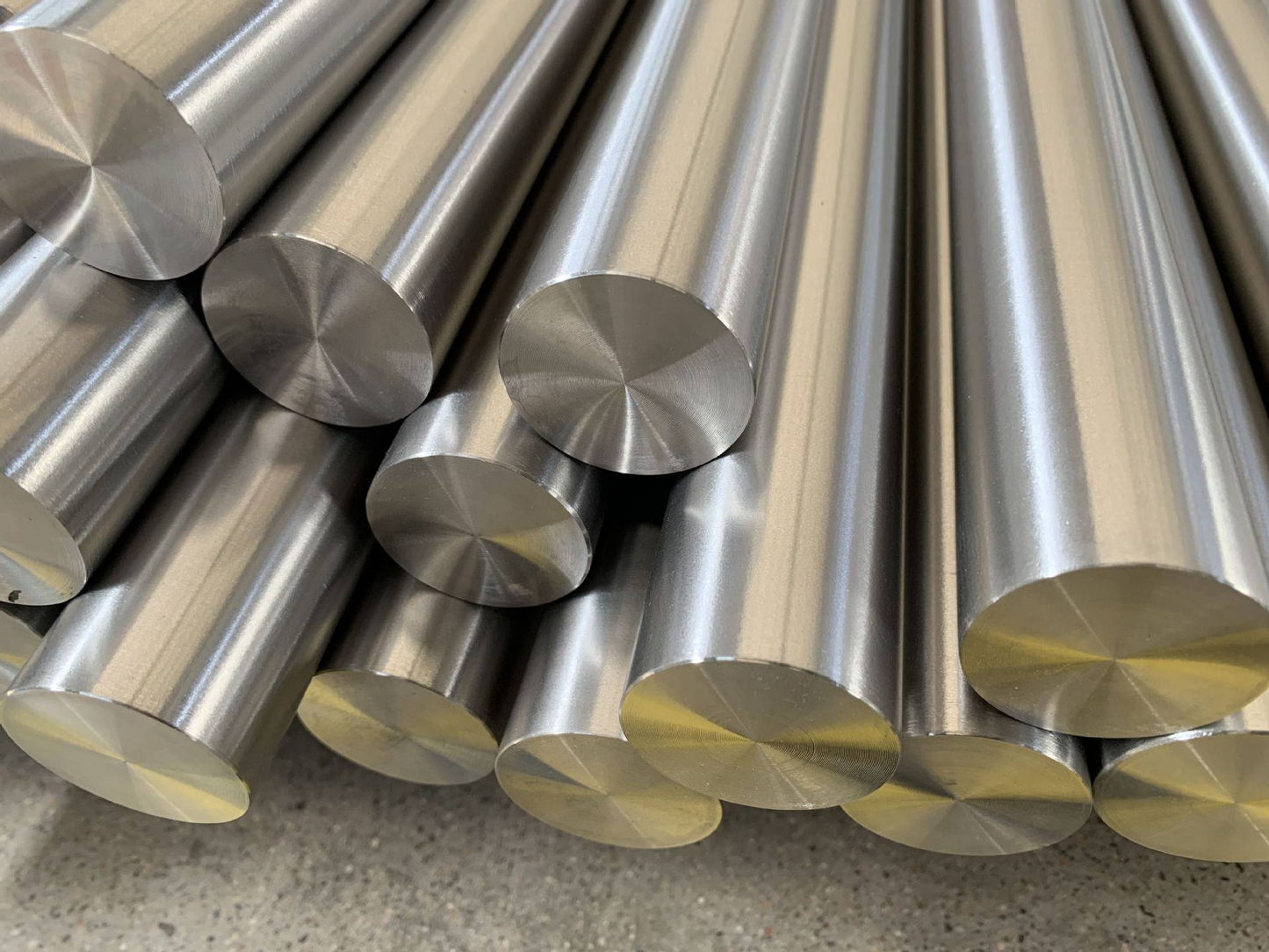

Product Overview

Características Metalúrgicas

ASTM A514 Grau S é um aço de baixa liga de alta resistência, temperado e revenido, apresentando uma microestrutura martensítica de grão fino com carbonetos temperados. A adição controlada de cromo, molibdênio e níquel proporciona maior endurecimento e resistência, mantendo excelentes características de tenacidade e soldabilidade.

Processo de Tratamento Térmico

MetalZenith emprega um tratamento de austenitização preciso a 900-950°C seguido de resfriamento em água para alcançar a estrutura martensítica desejada. O revenimento subsequente a 580-650°C otimiza o equilíbrio entre resistência e tenacidade, aliviando as tensões internas. Nosso tratamento térmico controlado por computador garante propriedades uniformes em toda a seção transversal do material.

Processo de Fabricação

A produção começa com a fusão em forno de arco elétrico utilizando sucata de alta qualidade e adições de liga, seguida de refino em panela e desgasificação a vácuo para alcançar a limpeza ideal. A fundição contínua produz lingotes de alta qualidade que são laminados a quente para dimensões finais. O processo de resfriamento e revenimento é realizado em nossas instalações de tratamento térmico de última geração com controle preciso da atmosfera.

Padrões de Qualidade & Testes

Cada lote de produção passa por testes abrangentes, incluindo análise química por espectroscopia de emissão óptica, testes de tração e impacto conforme os padrões ASTM, verificação de dureza e inspeção ultrassônica para integridade interna. Certificados de teste de fábrica fornecem rastreabilidade completa e documentação de conformidade. Testes adicionais, como fadiga, tenacidade à fratura e testes de soldabilidade, estão disponíveis mediante solicitação.

Considerações sobre Soldagem

ASTM A514 Grau S apresenta excelente soldabilidade quando os procedimentos adequados são seguidos. O pré-aquecimento a 150-200°C é recomendado para seções grossas, com controle da temperatura entre passes abaixo de 250°C. O alívio de tensões pós-soldagem pode ser necessário para aplicações críticas. MetalZenith fornece especificações abrangentes de procedimentos de soldagem e suporte técnico para desempenho ideal das juntas.

🧪 Chemical Composition

| Elemento | Composição (%) |

|---|---|

| Carbono (C) | 0.15-0.21 |

| Manganês (Mn) | 0.70-1.00 |

| Silício (Si) | 0.20-0.35 |

| Fósforo (P) | ≤ 0.035 |

| Enxofre (S) | ≤ 0.035 |

| Cromo (Cr) | 0.50-0.80 |

| Níquel (Ni) | 0.30-0.70 |

| Molibdênio (Mo) | 0.18-0.28 |

| Cobre (Cu) | ≤ 0.35 |

| Alumínio (Al) | 0.020-0.050 |

| Nitrogênio (N) | ≤ 0.015 |

| Vanádio (V) | 0.03-0.08 |

⚙️ Mechanical Properties

| Propriedade | Valor |

|---|---|

| Resistência à Tração | 760-895 MPa (110-130 ksi) |

| Resistência ao Escoamento (deslocamento de 0,2%) | ≥ 690 MPa (100 ksi) |

| Alongamento em 50mm | ≥ 18% |

| Redução de Área | ≥ 45% |

| Dureza (Brinell) | 235-293 HB |

| Energia de Impacto (Charpy V-notch a 0°C) | ≥ 34 J (25 ft-lbs) |

| Limite de Fadiga (10^7 ciclos) | 380 MPa |

| Módulo de Elasticidade | 200 GPa |

| Razão de Poisson | 0.27-0.30 |

| Módulo de Cisalhamento | 80 GPa |

🔬 Physical Properties

| Propriedade | Valor |

|---|---|

| Densidade | 7.85 g/cm³ |

| Ponto de Fusão | 1425-1470°C |

| Condutividade Térmica (a 20°C) | 42 W/m·K |

| Coeficiente de Expansão Térmica (20-100°C) | 12.5×10-6/K |

| Capacidade Calorífica Específica | 460 J/kg·K |

| Resistividade Elétrica | 0.20 µΩ·m |

| Permeabilidade Magnética | Ferromagnético |

| Temperatura de Curie | 770°C |

| Difusividade Térmica | 11.6 mm²/s |

📏 Product Specifications

| Especificação | Detalhes |

|---|---|

| Formas Disponíveis | Placas, Folhas, Barras, Formas Estruturais |

| Faixa de Espessura da Placa | 6-150mm (0.25-6 polegadas) |

| Faixa de Espessura da Folha | 1.5-6mm (0.06-0.25 polegadas) |

| Faixa de Diâmetro da Barra | 10-300mm (0.4-12 polegadas) |

| Conformidade com Normas | ASTM A514, ASTM A709 Grau 100 |

| Acabamento de Superfície | Laminado a Quente, Desengordurado, Jateado |

| Condição da Borda | Borda de Serralheria, Cortada, Cortada a Chama, Usinada |

| Tolerância Dimensional | Norma ASTM A6/A6M |

| Tolerância de Planicidade | ≤ 5mm/m |

| Faixa de Comprimento | Até 18m (comprimentos personalizados disponíveis) |

Vamos Criar Sucesso para o Seu Projeto

Equipe Profissional, Produtos Premium, Serviço Completo - O Sucesso do Seu Projeto é Nossa Missão

Our Advantages in Processing ASTM A514 Grau S

Tecnologia Avançada de Tratamento Térmico

MetalZenith emprega processos de têmpera e revenimento controlados por precisão, com perfis de temperatura monitorados por computador, garantindo propriedades mecânicas consistentes e uma microestrutura ideal em toda a espessura do material para um desempenho superior.

Sistema Abrangente de Controle de Qualidade

Nosso sistema integrado de gestão da qualidade inclui análise química em tempo real, testes mecânicos automatizados, inspeção ultrassônica e verificação dimensional, garantindo que cada produto atenda ou supere as especificações ASTM A514 Grade S.

Processamento Personalizado e Suprimento Global

MetalZenith oferece amplas capacidades de personalização, incluindo corte de precisão, conformação e tratamentos de superfície, apoiados por nossa rede de distribuição global que garante a entrega pontual de soluções sob medida em todo o mundo.

SEU CONFIÁVEL AÇO

PARCEIRO DE MANUFATURA

Quick Inquiry

Indústrias que Atendemos

Soluções de aço profissionais em grandes indústrias

Qualificações e Certificações