20 Anos de Experiência | 1000+ Parceiros de Marca | Personalização Completa

Temos 20 anos de experiência na indústria, fizemos parceria com mais de 1.000 marcas e apoiamos quaisquer necessidades de personalização.

Technical Specifications

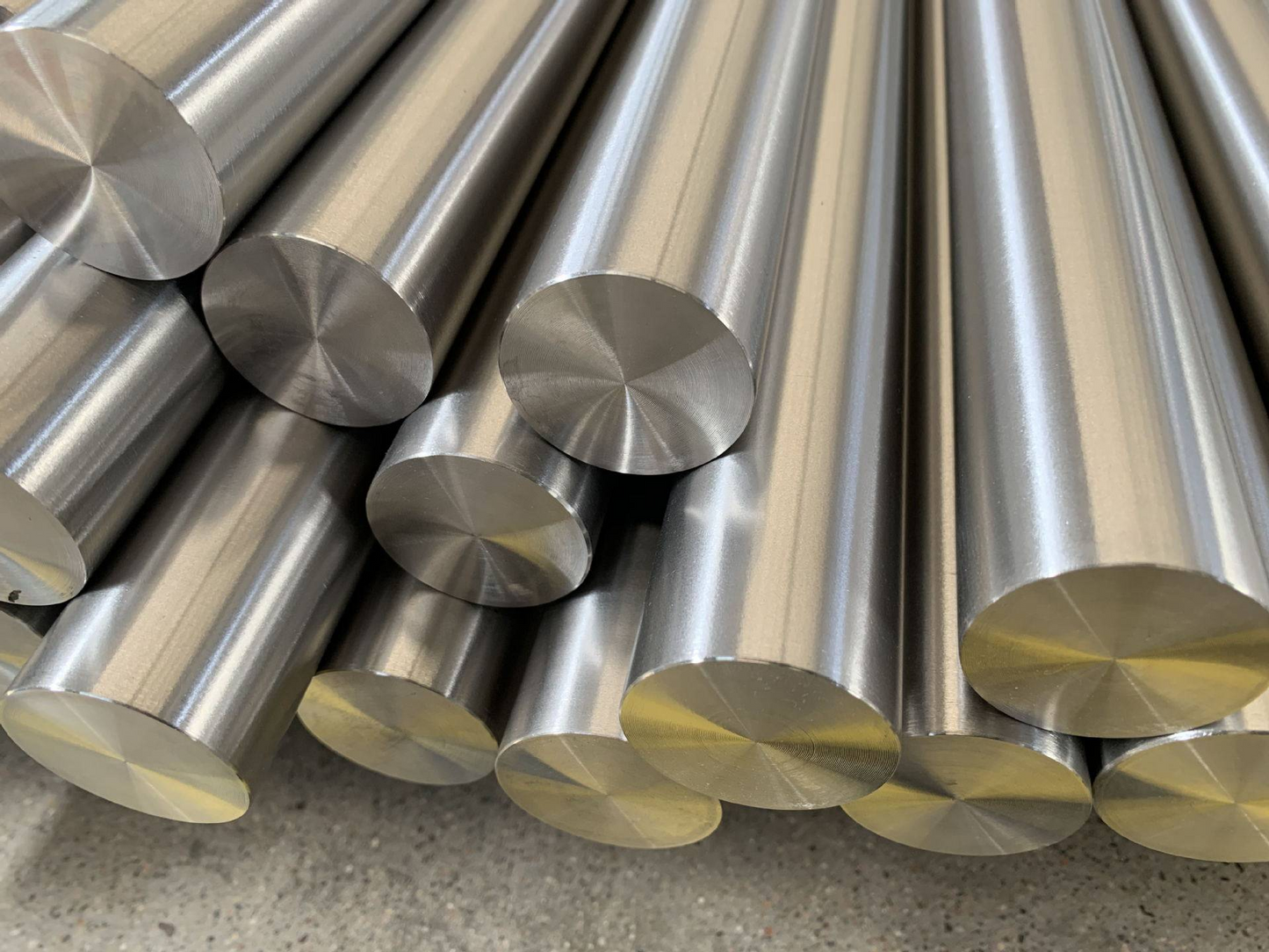

Product Overview

Características Metalúrgicas

API 5L X65 é um aço de alta resistência e baixo teor de liga (HSLA) especificamente projetado para aplicações em tubulações que exigem relações superiores de resistência-peso e excelente soldabilidade. O aço alcança suas propriedades aprimoradas através de microligação controlada com elementos como nióbio, vanádio e titânio, combinados com processamento termomecânico controlado (TMCP) para alcançar microestruturas de ferrita-perlita de grão fino.

Processo de Fabricação

A MetalZenith emprega processos avançados de fabricação de aço, incluindo fusão em forno de arco elétrico (EAF), refino em panela e fundição contínua para alcançar controle preciso da composição química. O processo de laminação a quente utiliza temperaturas de laminação controladas entre 1050-1150°C, seguido de resfriamento acelerado até a temperatura ambiente. Essa abordagem TMCP garante um refino ótimo do grão e efeitos de endurecimento por precipitação dos elementos de microligação.

Tratamento Térmico & Processamento

O aço grau X65 é tipicamente fornecido na condição como laminado, eliminando a necessidade de tratamento térmico adicional. Para aplicações especializadas, a normalização a 900-950°C pode ser realizada para alcançar uma microestrutura uniforme e alívio de tensões. Os procedimentos de soldagem devem seguir os requisitos da API 1104 ou da Seção IX da ASME, com temperaturas de pré-aquecimento geralmente variando de 50-150°C, dependendo da espessura e das condições ambientais.

Normas de Qualidade & Conformidade

Todos os produtos MetalZenith API 5L X65 estão em conformidade com os requisitos da Especificação API 5L 45ª Edição para os níveis de especificação de produto PSL1 e PSL2. A conformidade adicional inclui normas ASTM A106, EN 10208-2 e ISO 3183. Protocolos de teste abrangentes incluem análise química conforme ASTM E415, teste de tração conforme ASTM A370, teste de impacto Charpy V-notch conforme ASTM A370 e teste não destrutivo conforme os requisitos da API 5L. Serviços de inspeção e certificação de terceiros estão disponíveis através de agências acreditadas, incluindo DNV, SGS e TÜV.

🧪 Chemical Composition

| Elemento | PSL1 (%) | PSL2 (%) |

|---|---|---|

| Carbono (C) | ≤ 0.28 | ≤ 0.16 |

| Manganês (Mn) | ≤ 1.40 | ≤ 1.65 |

| Fósforo (P) | ≤ 0.030 | ≤ 0.025 |

| Enxofre (S) | ≤ 0.030 | ≤ 0.015 |

| Silício (Si) | ≤ 0.45 | ≤ 0.45 |

| Cromo (Cr) | - | ≤ 0.30 |

| Níquel (Ni) | - | ≤ 0.30 |

| Molibdênio (Mo) | - | ≤ 0.15 |

| Cobre (Cu) | - | ≤ 0.50 |

| Nióbio (Nb) | - | ≤ 0.05 |

| Vanádio (V) | - | ≤ 0.10 |

| Titânio (Ti) | - | ≤ 0.04 |

| Equivalente de Carbono (CE) | ≤ 0.43 | ≤ 0.43 |

| Equivalente de Carbono (Pcm) | - | ≤ 0.25 |

⚙️ Mechanical Properties

| Propriedade | PSL1 | PSL2 |

|---|---|---|

| Resistência ao Esforço (Rp0.2) | 450-570 MPa | 450-570 MPa |

| Resistência à Tração (Rm) | 535-760 MPa | 535-760 MPa |

| Relação de Esforço a Tração | ≤ 0.93 | ≤ 0.93 |

| Alongamento (A) | ≥ 18% | ≥ 18% |

| Energia de Impacto Charpy V-Notch (0°C) | - | ≥ 68 J |

| Energia de Impacto Charpy V-Notch (-10°C) | - | ≥ 40 J |

| Energia de Impacto Charpy V-Notch (-20°C) | - | ≥ 27 J |

| Dureza (HV10) | ≤ 250 | ≤ 250 |

| Teste de Queda de Peso (DWTT) | - | ≥ 85% Área de Cisalhamento |

| Limite de Fadiga (10^7 ciclos) | 180-220 MPa | 180-220 MPa |

| Tenacidade à Fratura (KIC) | - | ≥ 150 MPa·m^0.5 |

| Módulo de Elasticidade | 210 GPa | 210 GPa |

🔬 Physical Properties

| Propriedade | Valor | Unidades |

|---|---|---|

| Densidade | 7.85 | g/cm³ |

| Ponto de Fusão | 1510-1540 | °C |

| Condutividade Térmica (20°C) | 54 | W/m·K |

| Coeficiente de Expansão Térmica (20-100°C) | 12×10-6 | /K |

| Capacidade Calorífica Específica | 500 | J/kg·K |

| Resistividade Elétrica (20°C) | 0.16 | µΩ·m |

| Permeabilidade Magnética | Ferromagnético | - |

| Temperatura de Curie | 770 | °C |

| Razão de Poisson | 0.27-0.30 | - |

| Difusividade Térmica | 13.8 | mm²/s |

| Coeficiente de Expansão Linear (0-100°C) | 11.5×10-6 | /°C |

| Emissividade (Superfície Oxidada) | 0.79 | - |

📏 Product Specifications

| Especificação | Opções Disponíveis | Normas |

|---|---|---|

| Formas de Produto | Tubos Sem Costura, Tubos Soldados, Placas, Bobinas, Folhas | API 5L, ASTM A106 |

| Faixa de Diâmetro do Tubo | 6.35-1422 mm (1/4'-56') | API 5L |

| Espessura da Parede | 2.11-80 mm | API 5L |

| Espessura da Placa | 6-150 mm | API 5L, ASTM A516 |

| Largura da Bobina | 1000-2500 mm | API 5L |

| Comprimento | Aleatório Único (4-7m), Aleatório Duplo (10-12m), Comprimento Fixo | API 5L |

| Acabamento da Extremidade | Extremidade Lisa, Extremidade Chanfrada, Rosqueada & Acoplada | API 5L |

| Acabamento da Superfície | Preto, Galvanizado, Revestido com Epóxi, Revestido com 3PE | API 5L, ISO 21809 |

| Tolerância Dimensional | ±0.5% (OD), ±10% (WT) | API 5L |

| Requisitos de Teste | Hidroestático, NDT, Análise Química, Teste Mecânico | API 5L PSL1/PSL2 |

| Marcação | Estampado, Baixa Tensão, Gravado a Laser | API 5L |

| Embalagem | Agrupado, Caixas de Madeira, Estruturas de Aço, Embalagem para Exportação | Requisitos Personalizados |

Vamos Criar Sucesso para o Seu Projeto

Equipe Profissional, Produtos Premium, Serviço Completo - O Sucesso do Seu Projeto é Nossa Missão

Our Advantages in Processing API 5L X65

Tecnologia Avançada de Fabricação TMCP

MetalZenith emprega Processamento Termomecânico Controlado (TMCP) de ponta com controle de temperatura preciso e sistemas de resfriamento acelerado. Nossos modernos laminadores alcançam um refinamento de grão e controle de microestrutura ideais, resultando em um equilíbrio superior entre resistência e tenacidade e melhor soldabilidade em comparação com métodos de processamento convencionais.

Sistemas Abrangentes de Controle de Qualidade

Nosso sistema integrado de gestão da qualidade apresenta monitoramento em tempo real da composição química, testes mecânicos automatizados e capacidades avançadas de testes não destrutivos. Cada bobina e chapa passa por testes ultrassônicos, verificação dimensional e inspeção de qualidade da superfície para garantir 100% de conformidade com as especificações API 5L e os requisitos do cliente.

Cadeia de Suprimentos Global e Personalização

MetalZenith mantém locais estratégicos de inventário em todo o mundo e oferece amplas capacidades de personalização, incluindo modificações de química específica, tolerâncias dimensionais, tratamentos de superfície e soluções de embalagem. Nossa programação de produção flexível e rede logística garantem entrega confiável para projetos de pipeline globalmente, com documentação de rastreabilidade completa.

SEU CONFIÁVEL AÇO

PARCEIRO DE MANUFATURA

Quick Inquiry

Indústrias que Atendemos

Soluções de aço profissionais em grandes indústrias

Qualificações e Certificações