20 Anos de Experiência | 1000+ Parceiros de Marca | Personalização Completa

Temos 20 anos de experiência na indústria, fizemos parceria com mais de 1.000 marcas e apoiamos quaisquer necessidades de personalização.

Technical Specifications

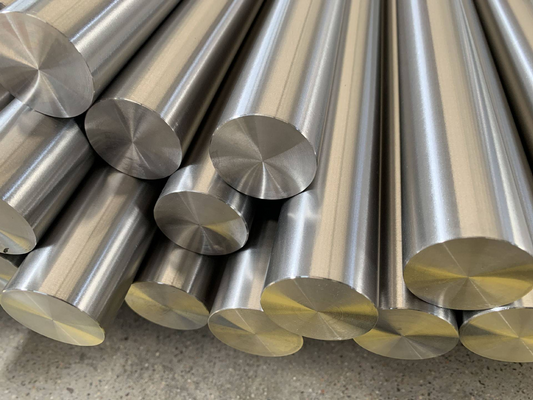

Product Overview

Características Metalúrgicas

API 5L X52 é um aço de baixo carbono e alta resistência com uma microestrutura predominantemente ferrítica-perlítica. A composição química controlada, particularmente o equivalente de carbono (CE) ≤ 0,43%, garante excelente soldabilidade enquanto mantém as propriedades mecânicas exigidas. A microestrutura de grão fino é alcançada através de laminação controlada e processos de resfriamento acelerado, resultando em um equilíbrio ótimo entre resistência e tenacidade.

Tratamento Térmico e Processamento

MetalZenith emprega processamento termomecânico controlado (TMCP) para a produção de API 5L X52. O aço passa por laminação controlada a temperaturas entre 850-950°C, seguido de resfriamento acelerado para alcançar a microestrutura desejada. O tratamento térmico de normalização a 900-950°C pode ser aplicado para alívio de tensões e refino de grãos. O tratamento térmico pós-solda (PWHT) a 580-650°C é recomendado para componentes soldados de seção grossa.

Excelência no Processo de Fabricação

Nosso processo de fabricação integrado começa com a produção de aço em forno a arco elétrico, utilizando metalurgia de panela avançada para controle preciso da composição química. A fundição contínua garante uma estrutura homogênea, seguida de laminação a quente em usinas de última geração com controle de processo computadorizado. Tubos sem costura são produzidos através de perfuração rotativa e laminação pilger, enquanto tubos soldados utilizam soldagem por indução de alta frequência com inspeção de costura de 100%.

Padrões de Qualidade e Conformidade

O aço API 5L X52 da MetalZenith atende a rigorosos padrões internacionais, incluindo os requisitos API 5L PSL1 e PSL2, NACE MR0175 para aplicações em serviços ácidos e vários padrões nacionais. Nosso sistema de gestão da qualidade abrange controle estatístico de processos, monitoramento em tempo real de parâmetros críticos e protocolos de teste abrangentes, incluindo análise química, testes mecânicos, exame não destrutivo e testes de pressão hidrostática para garantir qualidade e confiabilidade consistentes do produto.

🧪 Chemical Composition

| Elemento | Composição (%) |

|---|---|

| Carbono (C) | ≤ 0.26 |

| Manganês (Mn) | ≤ 1.40 |

| Silício (Si) | ≤ 0.45 |

| Fósforo (P) | ≤ 0.030 |

| Enxofre (S) | ≤ 0.030 |

| Cromo (Cr) | ≤ 0.30 |

| Níquel (Ni) | ≤ 0.30 |

| Molibdênio (Mo) | ≤ 0.15 |

| Cobre (Cu) | ≤ 0.50 |

| Vanádio (V) | ≤ 0.10 |

| Nióbio (Nb) | ≤ 0.05 |

| Titânio (Ti) | ≤ 0.04 |

| Alumínio (Al) | ≤ 0.06 |

| Equivalente de Carbono (CE) | ≤ 0.43 |

⚙️ Mechanical Properties

| Propriedade | Valor |

|---|---|

| Resistência ao Esforço (Rt0.5) | 360-530 MPa |

| Resistência à Tração (Rm) | 460-760 MPa |

| Alongamento (A) | ≥ 22% |

| Relação de Esforço a Tração | ≤ 0.93 |

| Dureza (HB) | 150-250 |

| Energia de Impacto (CVN a 0°C) | ≥ 27 J |

| Energia de Impacto (CVN a -20°C) | ≥ 20 J |

| Limite de Fadiga (107 ciclos) | 180-220 MPa |

| Módulo de Young | 210 GPa |

| Razão de Poisson | 0.30 |

| Módulo de Cisalhamento | 80 GPa |

| Resistência à Compressão | 360-530 MPa |

🔬 Physical Properties

| Propriedade | Valor |

|---|---|

| Densidade | 7.85 g/cm³ |

| Ponto de Fusão | 1510°C |

| Condutividade Térmica (20°C) | 54 W/m·K |

| Coeficiente de Expansão Térmica (20-100°C) | 12×10-6/K |

| Capacidade Calorífica Específica | 500 J/kg·K |

| Resistividade Elétrica (20°C) | 0.16 µΩ·m |

| Permeabilidade Magnética | Ferromagnético |

| Temperatura de Curie | 770°C |

| Difusividade Térmica | 13.8 mm²/s |

| Emissividade (superfície oxidada) | 0.79 |

| Velocidade do Som (longitudinal) | 5900 m/s |

| Módulo de Compressão | 160 GPa |

📏 Product Specifications

| Especificação | Opções Disponíveis |

|---|---|

| Formas de Produto | Tubos Sem Costura, Tubos Soldados, Placas, Bobinas, Folhas |

| Faixa de Diâmetro do Tubo | 6.35-1422 mm (0.25-56 polegadas) |

| Espessura da Parede | 2.11-80 mm (0.083-3.15 polegadas) |

| Espessura da Placa | 6-100 mm |

| Faixa de Comprimento | 5.8-18.3 m (Comprimento Aleatório ou Fixo) |

| Normas de Fabricação | API 5L, ASTM A106, ASME B36.10M, EN 10208 |

| Acabamento da Extremidade | Extremidade Lisa, Extremidade Chanfrada, Rosqueada e Acoplada |

| Acabamento da Superfície | Preto, Galvanizado, Revestido com 3PE, Revestido com FBE |

| Tolerância Dimensional | ±1% (Diâmetro), ±12.5% (Espessura da Parede) |

| Requisitos de Teste | Hidroestático, NDT, Análise Química, Teste Mecânico |

| Certificação | Certificado de Teste de Fábrica, Inspeção de Terceiros |

| Embalagem | Feixes, Caixas de Madeira, Estruturas de Aço |

Vamos Criar Sucesso para o Seu Projeto

Equipe Profissional, Produtos Premium, Serviço Completo - O Sucesso do Seu Projeto é Nossa Missão

Our Advantages in Processing API 5L X52

Tecnologia Avançada de Laminação Controlada

MetalZenith emprega processos sofisticados de laminação controlada e resfriamento acelerado que otimizam a estrutura do grão e melhoram as propriedades mecânicas, oferecendo aço API 5L X52 com uma relação resistência-peso superior e soldabilidade excepcional para aplicações críticas em tubulações.

Sistemas Abrangentes de Controle de Qualidade

Nosso sistema integrado de gestão da qualidade apresenta monitoramento em tempo real da composição química, testes mecânicos automatizados e técnicas avançadas de exame não destrutivo, garantindo que cada produto API 5L X52 atenda às rigorosas especificações da API e aos requisitos dos clientes.

Excelência na Cadeia de Suprimentos Global

A rede de distribuição mundial da MetalZenith e suas capacidades de fabricação flexíveis permitem a entrega rápida de produtos API 5L X52 personalizados em várias formas, incluindo tubos sem costura, tubos soldados e materiais em chapa, com dimensões e acabamentos de superfície sob medida para atender a requisitos específicos do projeto.

SEU CONFIÁVEL AÇO

PARCEIRO DE MANUFATURA

Quick Inquiry

Indústrias que Atendemos

Soluções de aço profissionais em grandes indústrias

Qualificações e Certificações