20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

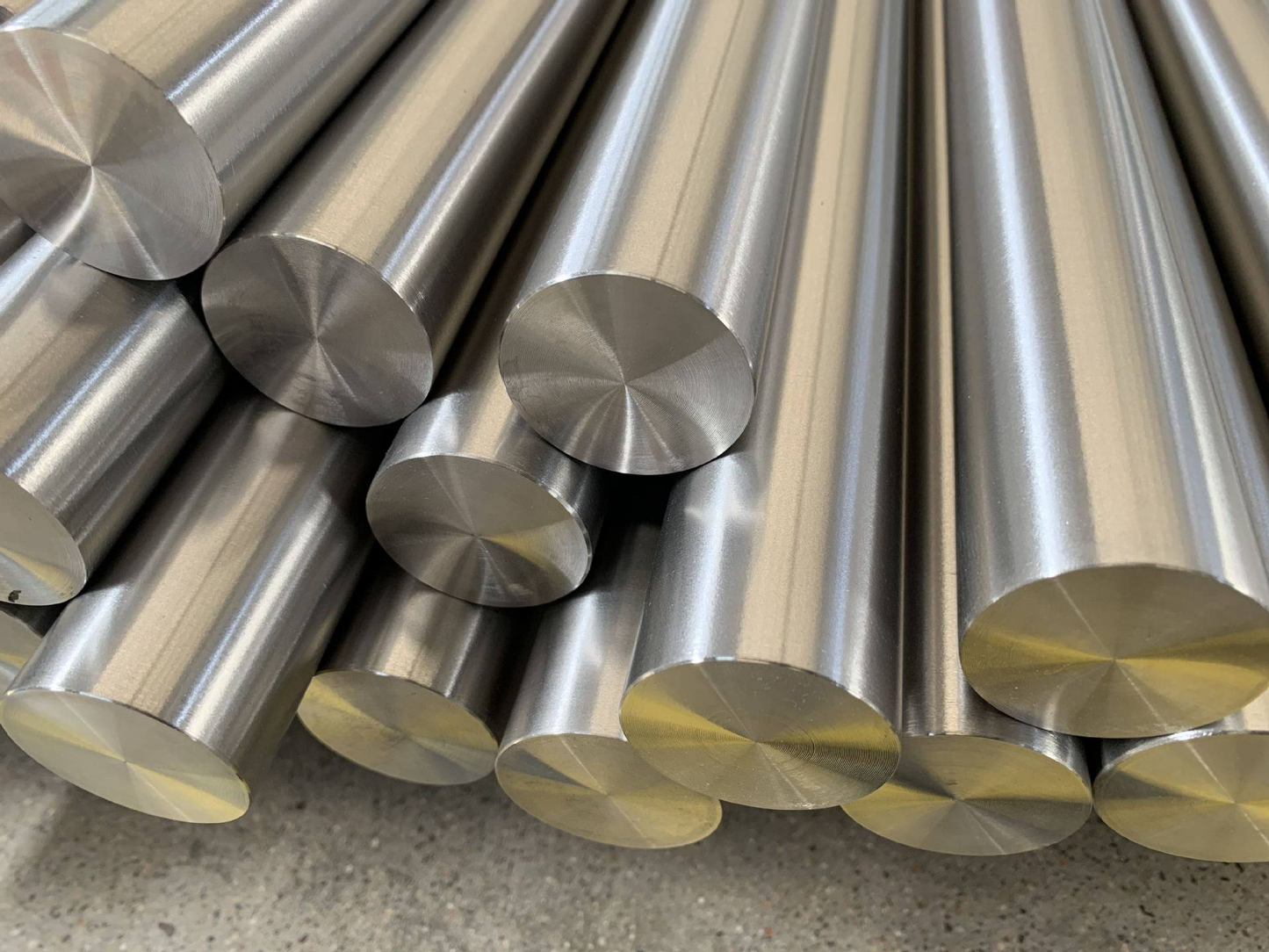

Product Overview

Metallurgical Characteristics

GB 00Cr17Ni14Mo2 exhibits a fully austenitic microstructure at room temperature, characterized by face-centered cubic crystal structure that provides excellent ductility and toughness. The low carbon content (≤ 0.030%) minimizes carbide precipitation, while molybdenum addition enhances pitting and crevice corrosion resistance, particularly in chloride environments.

Heat Treatment Process

MetalZenith employs precise solution annealing at 1040-1100°C followed by rapid cooling to achieve optimal properties. This process dissolves carbides, homogenizes the microstructure, and maximizes corrosion resistance. Post-annealing pickling removes heat tint and surface oxidation, ensuring superior surface quality.

Manufacturing Excellence

Our manufacturing process begins with carefully selected raw materials melted in electric arc furnaces with argon-oxygen decarburization (AOD) refining. Secondary metallurgy ensures precise chemistry control, while continuous casting produces high-quality billets. Subsequent hot rolling, cold working, and finishing operations are performed under strict quality control to achieve specified mechanical properties and surface finish.

Quality Standards and Certification

All GB 00Cr17Ni14Mo2 products undergo comprehensive testing including chemical analysis by optical emission spectroscopy, mechanical testing per ASTM standards, ultrasonic inspection for internal soundness, and dimensional verification. MetalZenith maintains ISO 9001:2015, ISO 14001:2015, and OHSAS 18001 certifications, ensuring consistent quality and environmental responsibility. Material test certificates (MTC) per EN 10204 3.1 are provided with every shipment, guaranteeing full traceability and compliance with international standards.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤ 0.030 |

| Silicon (Si) | ≤ 1.00 |

| Manganese (Mn) | ≤ 2.00 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 |

| Chromium (Cr) | 16.00 - 18.00 |

| Nickel (Ni) | 10.00 - 14.00 |

| Molybdenum (Mo) | 2.00 - 3.00 |

| Nitrogen (N) | ≤ 0.10 |

| Iron (Fe) | Balance |

⚙️ Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ≥ 485 MPa |

| Yield Strength (0.2% Offset) | ≥ 205 MPa |

| Elongation (A50) | ≥ 40% |

| Reduction of Area | ≥ 60% |

| Hardness (HB) | ≤ 187 |

| Hardness (HV) | ≤ 200 |

| Impact Energy (KV2, 20°C) | ≥ 120 J |

| Young's Modulus | 200 GPa |

| Fatigue Limit (107 cycles) | 240 MPa |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density (20°C) | 8.00 g/cm³ |

| Melting Point | 1375-1400°C |

| Thermal Conductivity (20°C) | 16.3 W/m·K |

| Thermal Expansion (20-100°C) | 16.0×10-6/K |

| Thermal Expansion (20-300°C) | 16.8×10-6/K |

| Specific Heat Capacity | 500 J/kg·K |

| Electrical Resistivity (20°C) | 0.74 µΩ·m |

| Magnetic Permeability | 1.02 (Non-magnetic) |

| Poisson's Ratio | 0.27-0.30 |

📏 Product Specifications

| Specification | Available Options |

|---|---|

| Product Forms | Round bars, square bars, flat bars, sheets, plates, tubes, pipes, forgings |

| Round Bar Diameter | 6mm - 300mm |

| Square Bar Size | 10mm - 150mm |

| Sheet Thickness | 0.5mm - 6mm |

| Plate Thickness | 6mm - 100mm |

| Tube Outer Diameter | 6mm - 219mm |

| Surface Finish | Hot rolled, cold rolled, bright annealed, pickled, polished |

| Standards Compliance | GB/T 20878, ASTM A240, EN 10088, JIS G4305 |

| Dimensional Tolerance | ±0.1mm to ±0.5mm (depending on form and size) |

| Length Options | Standard lengths: 3m, 6m, 12m; Custom lengths available |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing GB 00Cr17Ni14Mo2

Advanced Vacuum Melting Technology

MetalZenith utilizes cutting-edge vacuum induction melting (VIM) and electroslag remelting (ESR) processes to achieve exceptional chemical homogeneity and purity in GB 00Cr17Ni14Mo2 production. Our controlled atmosphere melting eliminates impurities and ensures consistent microstructure throughout the material.

Comprehensive Quality Control System

Our integrated quality management system includes real-time chemical analysis, advanced mechanical testing, and complete dimensional inspection. Every product batch receives full material certification with traceability documentation, ensuring compliance with international standards and customer specifications.

Flexible Customization Capabilities

MetalZenith offers extensive customization options including specialized heat treatments, precision machining, and custom dimensions. Our engineering team provides technical support for application-specific requirements, ensuring optimal material performance for each customer's unique needs.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications