20年の経験 | 1000以上のブランドパートナー | 完全なカスタマイズ

私たちは20年の業界経験があり、1,000以上のブランドと提携し、あらゆるカスタマイズニーズをサポートしています。

Technical Specifications

Product Overview

冶金特性

FH40は、主にフェライト-パーライトの微細構造を持つ正規化された微細粒構造鋼です。ニオブ、バナジウム、チタンなどの微合金元素の制御された添加は、粒子の細化と析出強化を促進し、オフショア用途に不可欠な優れた強度-靭性の組み合わせを実現します。

熱処理プロセス

MetalZenithは、900-950℃での正規化を伴う制御された圧延を行い、最適な微細構造の均一性を達成します。熱機械処理は、低サービス温度で必要な衝撃靭性を達成するために重要な微細オーステナイト粒サイズと均一な炭化物分布を確保します。

製造プロセス

生産は、電気アーク炉での溶解から始まり、次に鋳型精製と真空脱ガスを行い、超低硫黄およびリン含有量を達成します。連続鋳造により高品質のビレットが生成され、正確な温度制御で制御された圧延が行われます。最終的な正規化処理は、応力緩和と断面全体の最適な機械的特性を確保します。

品質基準と試験

すべての熱は、化学分析、引張試験、-40℃および-60℃でのシャルピーVノッチ衝撃試験、硬度試験、超音波検査を含む包括的な試験を受けます。微細構造の検査は、粒サイズの遵守と有害な包含物の不在を確認します。ABS、DNV-GL、ロイド登録、ビューローベリタスなどの主要な分類団体からの第三者認証が利用可能です。

溶接に関する考慮事項

FH40は、適切な予熱(通常、厚い部分で100-150℃)と制御されたインターパス温度で優れた溶接性を示します。低炭素等価(CEV ≤ 0.40)は、冷間割れのリスクを最小限に抑えます。重要な用途では、応力緩和のために溶接後の熱処理が必要になる場合があります。

🧪 Chemical Composition

| 元素 | 組成 (%) |

|---|---|

| 炭素 (C) | ≤ 0.18 |

| マンガン (Mn) | 0.90 - 1.60 |

| シリコン (Si) | 0.10 - 0.50 |

| リン (P) | ≤ 0.030 |

| 硫黄 (S) | ≤ 0.025 |

| アルミニウム (Al) | ≥ 0.015 |

| ニオブ (Nb) | 0.02 - 0.05 |

| バナジウム (V) | 0.05 - 0.10 |

| チタン (Ti) | 0.02 - 0.05 |

| 窒素 (N) | ≤ 0.012 |

| 銅 (Cu) | ≤ 0.35 |

| クロム (Cr) | ≤ 0.20 |

| ニッケル (Ni) | ≤ 0.40 |

| モリブデン (Mo) | ≤ 0.08 |

⚙️ Mechanical Properties

| 特性 | 値 |

|---|---|

| 降伏強度 (ReH) | 390 - 510 MPa |

| 引張強度 (Rm) | 510 - 660 MPa |

| 伸び (A5) | ≥ 20% |

| 衝撃エネルギー (KV at -40°C) | ≥ 34 J |

| 衝撃エネルギー (KV at -60°C) | ≥ 24 J |

| 硬度 (HB) | 150 - 220 |

| ヤング率 | 206 GPa |

| ポアソン比 | 0.30 |

| 疲労限界 (107 サイクル) | 180 MPa |

| 破壊靭性 (K1C) | 120 MPa·m1/2 |

| 降伏比 (ReH/Rm) | ≤ 0.80 |

🔬 Physical Properties

| プロパティ | 値 |

|---|---|

| 密度 | 7.85 g/cm³ |

| 融点 | 1510°C |

| 熱伝導率 (20°C) | 54 W/m·K |

| 熱膨張係数 (20-100°C) | 12×10-6/K |

| 比熱容量 | 500 J/kg·K |

| 電気抵抗率 (20°C) | 0.16 µΩ·m |

| 磁気透過率 | 強磁性 |

| キュリー温度 | 770°C |

| 熱拡散率 | 13.7 mm²/s |

| 線膨張係数 (0-100°C) | 11.5×10-6/K |

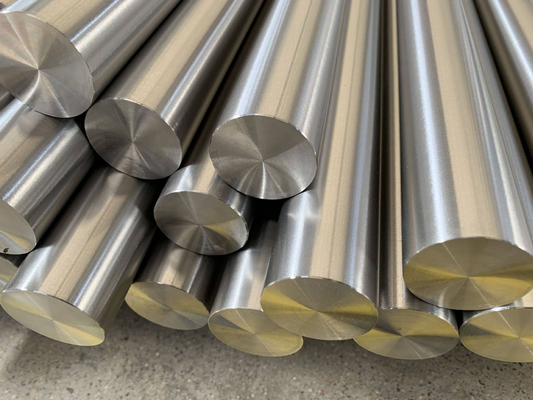

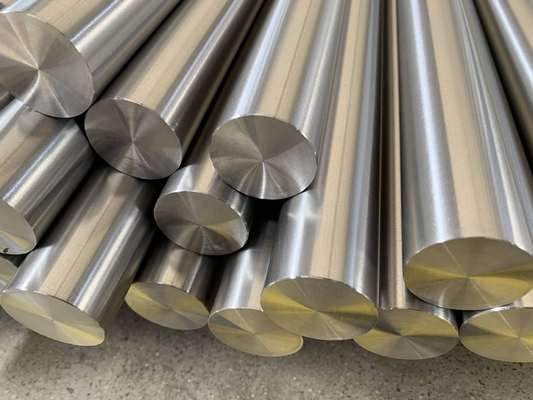

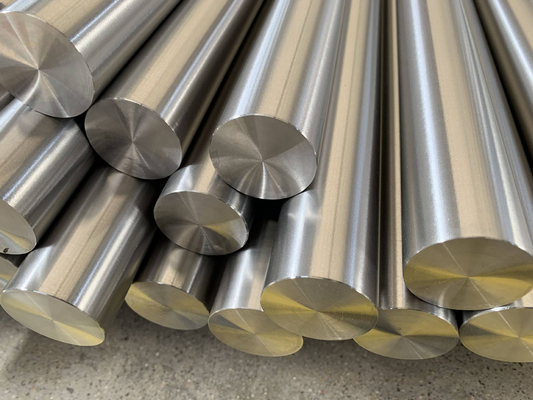

📏 Product Specifications

| 仕様 | 詳細 |

|---|---|

| 利用可能な形状 | プレート、シート、バー、セクション、鍛造品 |

| プレート厚さ範囲 | 6 - 150 mm |

| シート厚さ範囲 | 3 - 12 mm |

| 幅の範囲 | 1000 - 4000 mm |

| 長さの範囲 | 2000 - 18000 mm |

| 規格適合 | ABS、DNV-GL、LR、BV、NK、CCS、RINA |

| 表面仕上げ | 熱間圧延、正規化、ショットブラスト |

| エッジ状態 | ミルエッジ、シアード、フレームカット、機械加工 |

| 厚さ公差 | ±0.3 mm (6-40mm)、±0.5 mm (>40mm) |

| 幅公差 | ±5 mm |

| 長さ公差 | ±10 mm |

| 平坦度 | ≤ 5 mm/m |

あなたのプロジェクトの成功を共に創りましょう

プロフェッショナルチーム、プレミアム製品、完全なサービス - あなたのプロジェクトの成功は私たちの使命です

Our Advantages in Processing FH40

高度熱機械処理

MetalZenithは、最適な結晶構造と強化された機械的特性を達成するために、制御された圧延と正確な正規化プロセスを採用し、リアルタイムの温度監視を行っています。私たちの高度な加工により、材料の厚さ全体にわたって一貫した靭性と強度が確保されます。

包括的な品質テスト

私たちの最先端の試験施設では、-40℃でのシャルピーVノッチ衝撃試験、超音波検査、微細構造分析を含む完全な機械試験を実施しています。すべてのバッチは、オフショアの分類団体基準を満たすために厳格な品質検証を受けます。

カスタムオフショアソリューション

MetalZenithは、カスタム熱処理、精密切断、特別な表面処理を含むカスタマイズされた加工ソリューションを提供します。私たちのエンジニアリングチームは、特定のオフショアアプリケーションに対する技術サポートを提供し、タイムリーな配達のためのグローバルな物流能力を備えています。

あなたの信頼できる 鋼

製造パートナー

クイックお問い合わせ

私たちが提供する業界

主要産業向けのプロフェッショナルな鋼ソリューション

資格と認証