20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

Product Overview

Metallurgical Characteristics

CPM S30V is a martensitic stainless steel produced through Crucible Particle Metallurgy (CPM) technology, which involves rapid solidification of molten steel into fine powder particles followed by consolidation. This process results in a uniform distribution of fine vanadium carbides throughout the steel matrix, providing exceptional wear resistance and edge retention properties.

Manufacturing Process

MetalZenith employs advanced powder metallurgy techniques including gas atomization, hot isostatic pressing (HIP), and controlled atmosphere processing. The steel undergoes vacuum melting to ensure cleanliness, followed by rapid solidification to achieve fine carbide distribution. Subsequent consolidation processes eliminate porosity and achieve full density.

Heat Treatment Procedures

Annealing: Heat to 870-900°C, hold for 2-4 hours, cool slowly to achieve 255-285 HB hardness. Hardening: Austenitize at 1065-1095°C, quench in oil or air to achieve maximum hardness. Tempering: Temper at 150-540°C depending on desired hardness and toughness balance. Multiple tempering cycles may be employed for stress relief.

Quality Standards & Testing

All CPM S30V products undergo comprehensive quality control including chemical analysis by optical emission spectroscopy, hardness testing per ASTM E18, microstructural examination, and dimensional verification. MetalZenith maintains traceability records for each heat and implements statistical process control to ensure consistent quality. Products comply with international standards and customer-specific requirements.

Corrosion Resistance & Performance

The 14% chromium content provides excellent corrosion resistance in mild environments, while the high vanadium content (4%) forms hard vanadium carbides that contribute to superior wear resistance. The steel exhibits excellent edge retention and can maintain sharpness significantly longer than conventional tool steels, making it ideal for premium cutting applications.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | 1.45 |

| Chromium (Cr) | 14.00 |

| Vanadium (V) | 4.00 |

| Molybdenum (Mo) | 2.00 |

| Manganese (Mn) | 0.50 |

| Silicon (Si) | 0.50 |

| Phosphorus (P) | ≤ 0.030 |

| Sulfur (S) | ≤ 0.030 |

| Nickel (Ni) | ≤ 0.50 |

| Copper (Cu) | ≤ 0.25 |

⚙️ Mechanical Properties

| Property | Value |

|---|---|

| Hardness (HRC) - As Hardened | 58-61 |

| Hardness (HRC) - Tempered 200°C | 59-61 |

| Hardness (HRC) - Tempered 400°C | 56-58 |

| Tensile Strength | 2070-2275 MPa |

| Yield Strength (0.2% offset) | 1725-1930 MPa |

| Elongation | 1.5-2.5% |

| Reduction of Area | 3-5% |

| Impact Strength (Charpy V-notch) | 15-25 J |

| Fatigue Limit (107 cycles) | 900-1100 MPa |

| Modulus of Elasticity | 210 GPa |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density | 7.65 g/cm³ |

| Melting Point | 1480-1520°C |

| Thermal Conductivity (20°C) | 24.3 W/m·K |

| Thermal Expansion Coefficient (20-100°C) | 10.4×10-6/K |

| Thermal Expansion Coefficient (20-200°C) | 11.2×10-6/K |

| Specific Heat Capacity | 460 J/kg·K |

| Electrical Resistivity (20°C) | 0.60 µΩ·m |

| Magnetic Permeability | Ferromagnetic |

| Curie Temperature | ~450°C |

| Poisson's Ratio | 0.27-0.30 |

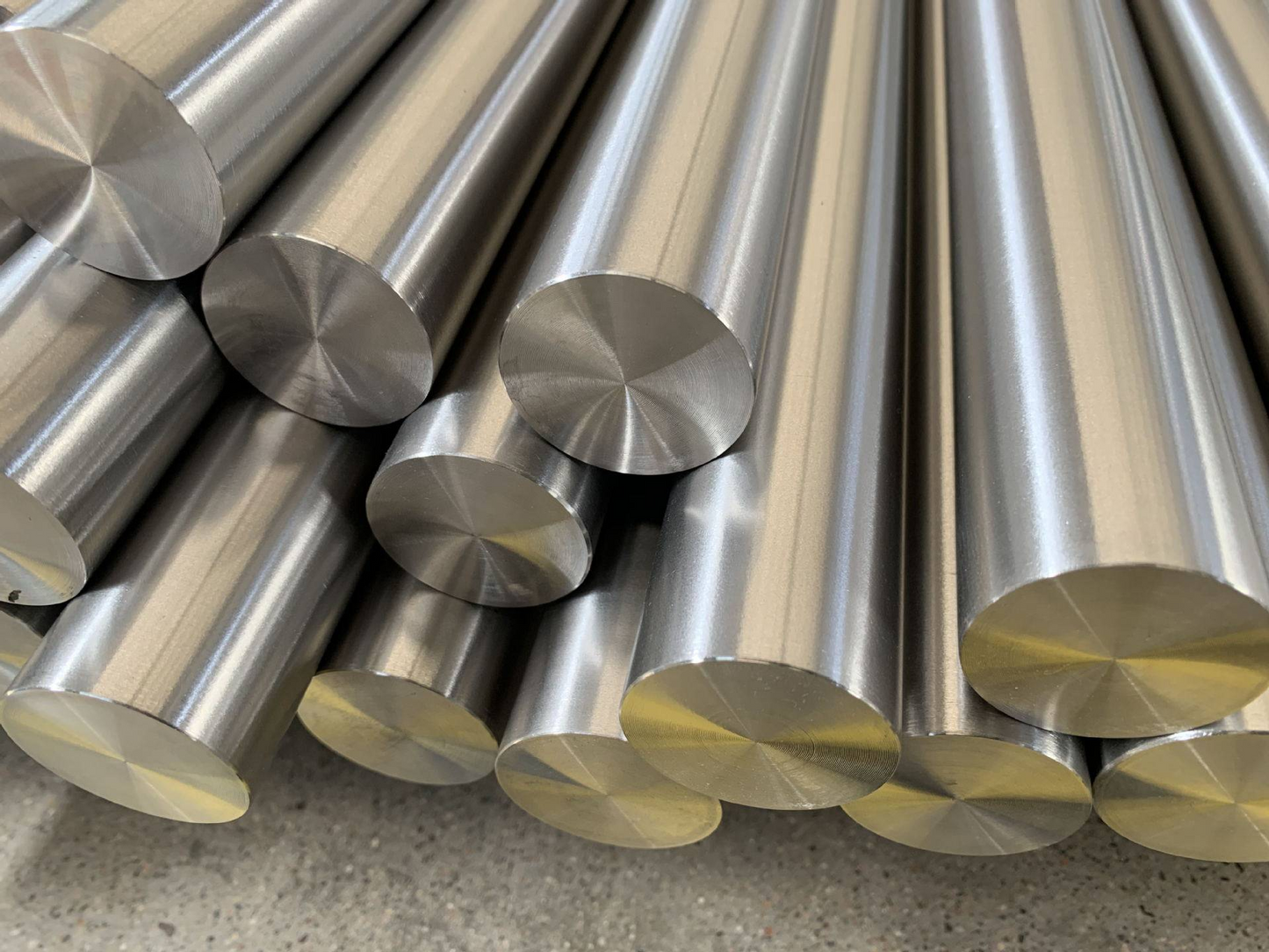

📏 Product Specifications

| Specification | Available Options |

|---|---|

| Product Forms | Round bars, flat bars, plates, sheets, custom shapes |

| Round Bar Diameter | 6mm - 300mm |

| Flat Bar Dimensions | 10×20mm - 100×500mm |

| Plate Thickness | 5mm - 150mm |

| Sheet Thickness | 0.5mm - 5mm |

| Length | Up to 6000mm (custom lengths available) |

| Surface Finish | Annealed, hardened & tempered, ground, polished |

| Dimensional Tolerance | ±0.1mm to ±0.5mm (depending on size) |

| Standards Compliance | ASTM A681, Custom specifications |

| Heat Treatment Condition | Annealed, spheroidized, hardened & tempered |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing CPM S30V

Advanced Powder Metallurgy Technology

MetalZenith employs cutting-edge Crucible Particle Metallurgy (CPM) processes with precise powder atomization and consolidation techniques, ensuring uniform carbide distribution and eliminating the segregation issues found in conventional cast steels, resulting in superior performance consistency.

Precision Heat Treatment & Quality Control

Our state-of-the-art vacuum heat treatment facilities with computer-controlled atmosphere management deliver precise hardness control and optimal microstructure. Comprehensive testing including chemical analysis, hardness mapping, and microstructural examination ensures every batch meets stringent quality standards.

Custom Processing & Global Supply Chain

MetalZenith offers extensive customization capabilities including precision machining, surface treatments, and specialized heat treatment cycles. Our global distribution network and flexible production scheduling ensure reliable supply chain management with competitive lead times for customers worldwide.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications