20 Tahun Pengalaman | 1000+ Mitra Merek | Kustomisasi Penuh

Kami memiliki 20 tahun pengalaman industri, telah bermitra dengan lebih dari 1.000 merek, dan mendukung kebutuhan kustomisasi apa pun.

Technical Specifications

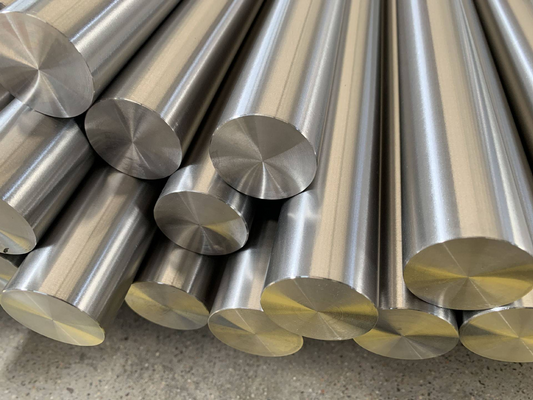

Product Overview

Karakteristik Metalurgi

GB 20G adalah baja karbon rendah dengan mikrostruktur ferritik-perlit yang dioptimalkan untuk aplikasi bejana tekan. Kandungan karbon yang terkontrol (0,17-0,24%) memberikan kemampuan pengelasan yang sangat baik sambil mempertahankan kekuatan yang memadai. Baja ini menunjukkan struktur butir halus yang dicapai melalui penggulungan terkontrol dan perlakuan panas normalisasi, memastikan sifat mekanik yang seragam di seluruh ketebalan material.

Proses Perlakuan Panas

MetalZenith menerapkan protokol perlakuan panas yang tepat termasuk normalisasi pada 900-950°C diikuti dengan pendinginan udara. Proses ini memperhalus struktur butir, mengurangi stres internal, dan mengoptimalkan sifat mekanik. Annealing pelepasan stres opsional pada 600-650°C dapat diterapkan untuk bagian berat untuk meminimalkan stres sisa dan meningkatkan stabilitas dimensi.

Proses Manufaktur

Proses produksi kami dimulai dengan peleburan furnace busur listrik menggunakan limbah premium dan tambahan paduan. Baja cair menjalani pemurnian ladle untuk kontrol kimia yang tepat dan penghilangan gas. Penuangan kontinu menghasilkan billet berkualitas tinggi, yang kemudian digulung panas menggunakan pabrik penggulungan yang dikendalikan komputer untuk mencapai dimensi dan sifat mekanik yang ditentukan.

Standar Kualitas & Pengujian

Setiap produk GB 20G yang diproduksi oleh MetalZenith menjalani pengujian komprehensif termasuk analisis kimia dengan spektroskopi emisi optik, pengujian tarik, pengujian impak pada suhu yang ditentukan, dan pemeriksaan ultrasonik untuk ketahanan internal. Sertifikat uji pabrik memberikan jejak lengkap dan verifikasi kepatuhan dengan GB 713 dan kode bejana tekan internasional.

🧪 Chemical Composition

| Elemen | Komposisi (%) |

|---|---|

| Karbon (C) | 0.17-0.24 |

| Mangan (Mn) | 0.35-0.65 |

| Silikon (Si) | 0.15-0.35 |

| Fosfor (P) | ≤ 0.035 |

| Belerang (S) | ≤ 0.035 |

| Krom (Cr) | ≤ 0.25 |

| Nikel (Ni) | ≤ 0.30 |

| Tembaga (Cu) | ≤ 0.25 |

| Aluminium (Al) | ≥ 0.020 |

⚙️ Mechanical Properties

| Properti | Nilai |

|---|---|

| Kekuatan Tarik | 410-550 MPa |

| Kekuatan Luluh (offset 0.2%) | ≥ 245 MPa |

| Panjang Regangan (L0=5d0) | ≥ 21% |

| Pengurangan Luas | ≥ 50% |

| Kekerasan Brinell (HB) | 123-179 |

| Energi Impak (KV2, 20°C) | ≥ 34 J |

| Modulus Young | 206 GPa |

| Batas Kelelahan (10^7 siklus) | 180-220 MPa |

🔬 Physical Properties

| Properti | Nilai |

|---|---|

| Kepadatan | 7.85 g/cm³ |

| Titik Leleh | 1510°C |

| Konduktivitas Termal (20°C) | 54 W/m·K |

| Koefisien Ekspansi Termal (20-100°C) | 12×10-6/K |

| Kapasitas Panas Spesifik | 460 J/kg·K |

| Resistivitas Listrik (20°C) | 0.16 µΩ·m |

| Permeabilitas Magnetik | Ferromagnetik |

| Suhu Curie | 770°C |

📏 Product Specifications

| Spesifikasi | Opsi Tersedia |

|---|---|

| Bentuk Produk | Piring, Lembaran, Batang, Forging, Tabung |

| Ketebalan Piring | 6-200 mm |

| Ketebalan Lembaran | 0.5-6 mm |

| Diameter Batang | 10-300 mm |

| Diameter Luar Tabung | 25-600 mm |

| Kepatuhan Standar | GB 713, ASME SA-516, EN 10028-2 |

| Finishing Permukaan | Dibuat Panas, Dinormalisasi, Diasamkan |

| Toleransi Dimensi | ±0.1-0.5 mm (tergantung ketebalan) |

| Suhu Kerja Maksimum | 475°C |

Mari Kita Ciptakan Kesuksesan untuk Proyek Anda

Tim Profesional, Produk Premium, Layanan Lengkap - Keberhasilan Proyek Anda adalah Misi Kami

Our Advantages in Processing GB 20G

Pemrosesan Metalurgi Lanjutan

MetalZenith menggunakan teknologi tungku busur listrik mutakhir dengan kontrol suhu yang tepat dan sistem metalurgi ladle otomatis, memastikan komposisi kimia yang konsisten dan kebersihan baja yang superior untuk kinerja bejana tekan yang optimal.

Sistem Pengendalian Kualitas yang Komprehensif

Sistem manajemen kualitas terintegrasi kami dilengkapi dengan pemantauan waktu nyata, analisis spektroskopi canggih, dan protokol pengujian mekanis lengkap, menjamin setiap produk GB 20G memenuhi atau melebihi standar bejana tekan internasional.

Manufaktur Kustom & Pasokan Global

MetalZenith menawarkan kemampuan produksi yang fleksibel dengan ukuran kustom, perlakuan panas khusus, dan layanan pemrosesan bernilai tambah, didukung oleh jaringan distribusi global kami untuk pengiriman yang dapat diandalkan ke lokasi mana pun.

ANDA YANG DIPERCAYA BAJA

MITRA MANUFAKTUR

Pertanyaan Cepat

Industri yang Kami Layani

Solusi baja profesional di berbagai industri

Kualifikasi & Sertifikasi