20 Tahun Pengalaman | 1000+ Mitra Merek | Kustomisasi Penuh

Kami memiliki 20 tahun pengalaman industri, telah bermitra dengan lebih dari 1.000 merek, dan mendukung kebutuhan kustomisasi apa pun.

Technical Specifications

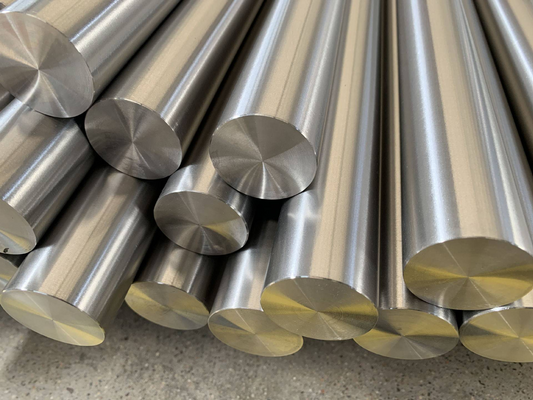

Product Overview

Karakteristik Metalurgi

AISI 1065 adalah baja karbon tinggi eutektik dengan kandungan karbon sekitar 0,65%, menempatkannya dekat dengan komposisi eutektik. Mikrostruktur dalam kondisi annealed terdiri dari perlit dengan beberapa ferit, memberikan kemampuan mesin yang baik sambil mempertahankan kekuatan yang memadai. Setelah perlakuan panas, baja ini mengembangkan struktur martensitik dengan kekerasan dan sifat pegas yang sangat baik.

Proses Perlakuan Panas

MetalZenith menerapkan protokol perlakuan panas yang tepat untuk baja AISI 1065. Austenisasi dilakukan pada 790-820°C, diikuti dengan pendinginan cepat dalam minyak atau air untuk mencapai kekerasan penuh. Tempering pada 400-500°C memberikan keseimbangan optimal antara kekerasan, kekuatan, dan ketangguhan untuk aplikasi pegas. Tungku atmosfer terkendali kami memastikan hasil yang konsisten dan minimal dekarburisasi.

Keunggulan Proses Manufaktur

Proses manufaktur kami dimulai dengan bahan baku yang dipilih dengan cermat yang dilebur dalam tungku busur listrik dengan kontrol kimia yang tepat. Proses pemurnian sekunder termasuk metalurgi ladle memastikan kebersihan dan homogenitas yang optimal. Penggulungan panas dilakukan menggunakan pabrik yang dikendalikan komputer untuk mencapai dimensi yang tepat dan kualitas permukaan yang superior. Operasi penarikan dingin memberikan sifat mekanik yang ditingkatkan dan akurasi dimensi.

Standar Kualitas & Pengujian

MetalZenith mempertahankan kontrol kualitas yang ketat sepanjang produksi, termasuk pemantauan pengecoran kontinu, pengujian ultrasonik untuk kekuatan internal, dan verifikasi sifat mekanik yang komprehensif. Sistem manajemen kualitas kami mematuhi ISO 9001:2015, AS9100D untuk aplikasi dirgantara, dan IATF 16949 untuk pelanggan otomotif. Setiap pengiriman mencakup laporan uji bersertifikat yang mendokumentasikan komposisi kimia, sifat mekanik, dan kepatuhan dimensi.

🧪 Chemical Composition

| Elemen | Komposisi (%) |

|---|---|

| Karbon (C) | 0.60 - 0.70 |

| Mangan (Mn) | 0.60 - 0.90 |

| Silikon (Si) | 0.15 - 0.30 |

| Fosfor (P) | ≤ 0.030 |

| Belerang (S) | ≤ 0.035 |

| Krom (Cr) | ≤ 0.25 |

| Nikel (Ni) | ≤ 0.25 |

| Molybdenum (Mo) | ≤ 0.06 |

| Tembaga (Cu) | ≤ 0.30 |

| Besi (Fe) | Sisa |

⚙️ Mechanical Properties

| Properti | Kondisi Annealed | Dikeraskan & Ditemper |

|---|---|---|

| Kekuatan Tarik | 630-780 MPa | 1380-1650 MPa |

| Kekuatan Luluh | 370-450 MPa | 1240-1480 MPa |

| Panjang Regangan (%) | 12-18 | 8-12 |

| Pengurangan Luas (%) | 35-45 | 25-35 |

| Kekerasan (HB) | 187-229 | 388-444 |

| Kekerasan (HRC) | - | 40-47 |

| Energi Impak (Charpy V) | 25-35 J | 15-25 J |

| Batas Kelelahan | 280-320 MPa | 550-650 MPa |

| Modulus Elastisitas | 200-210 GPa | 200-210 GPa |

🔬 Physical Properties

| Properti | Nilai |

|---|---|

| Kepadatan | 7.85 g/cm³ |

| Titik Leleh | 1460-1510°C |

| Konduktivitas Termal (20°C) | 46-50 W/m·K |

| Koefisien Ekspansi Termal (20-100°C) | 11.5×10-6/K |

| Kapasitas Panas Spesifik | 460-480 J/kg·K |

| Resistivitas Listrik (20°C) | 0.18-0.22 µΩ·m |

| Permeabilitas Magnetik | Ferromagnetik |

| Suhu Curie | 770°C |

| Rasio Poisson | 0.27-0.30 |

| Modulus Geser | 80-85 GPa |

📏 Product Specifications

| Spesifikasi | Opsi Tersedia |

|---|---|

| Bentuk Produk | Batang bulat, batang datar, batang persegi, kawat, strip, lembaran, pelat |

| Diameter Batang Bulat | 6mm - 300mm |

| Dimensi Batang Datar | 10×3mm - 200×50mm |

| Diameter Kawat | 0.5mm - 12mm |

| Ketebalan Lembaran/Pelat | 0.5mm - 100mm |

| Panjang | Hingga 12 meter (panjang kustom tersedia) |

| Finishing Permukaan | Ditarik panas, ditarik dingin, dikupas, digiling, dipoles |

| Toleransi | h9, h10, h11 (toleransi presisi tersedia) |

| Standar | ASTM A684, SAE J403, EN 10132-4, JIS G4801 |

| Perlakuan Panas | Dianil, dinormalisasi, dikeraskan & dipanaskan |

Mari Kita Ciptakan Kesuksesan untuk Proyek Anda

Tim Profesional, Produk Premium, Layanan Lengkap - Keberhasilan Proyek Anda adalah Misi Kami

Our Advantages in Processing AISI 1065

Teknologi Tungku Busur Listrik Lanjutan

MetalZenith memanfaatkan teknologi tungku busur listrik mutakhir dengan kontrol suhu yang tepat dan sistem pengisian otomatis, memastikan distribusi kandungan karbon yang optimal dan minimalnya kotoran dalam produksi baja AISI 1065 untuk sifat mekanik yang superior.

Sistem Pengendalian Kualitas yang Komprehensif

Laboratorium pengujian canggih kami dilengkapi dengan spektrometer emisi optik, mesin pengujian universal, dan peralatan metalografi, menyediakan analisis kimia lengkap, verifikasi sifat mekanik, dan pemeriksaan mikrostruktur untuk setiap batch baja AISI 1065.

Pemrosesan Kustom & Rantai Pasokan Global

MetalZenith menawarkan kemampuan kustomisasi yang luas termasuk perlakuan panas presisi, penyelesaian permukaan khusus, dan dimensi kustom. Jaringan distribusi global kami memastikan pengiriman produk baja AISI 1065 yang dapat diandalkan kepada pelanggan di seluruh dunia dengan dukungan teknis yang komprehensif.

ANDA YANG DIPERCAYA BAJA

MITRA MANUFAKTUR

Pertanyaan Cepat

Industri yang Kami Layani

Solusi baja profesional di berbagai industri

Kualifikasi & Sertifikasi