20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

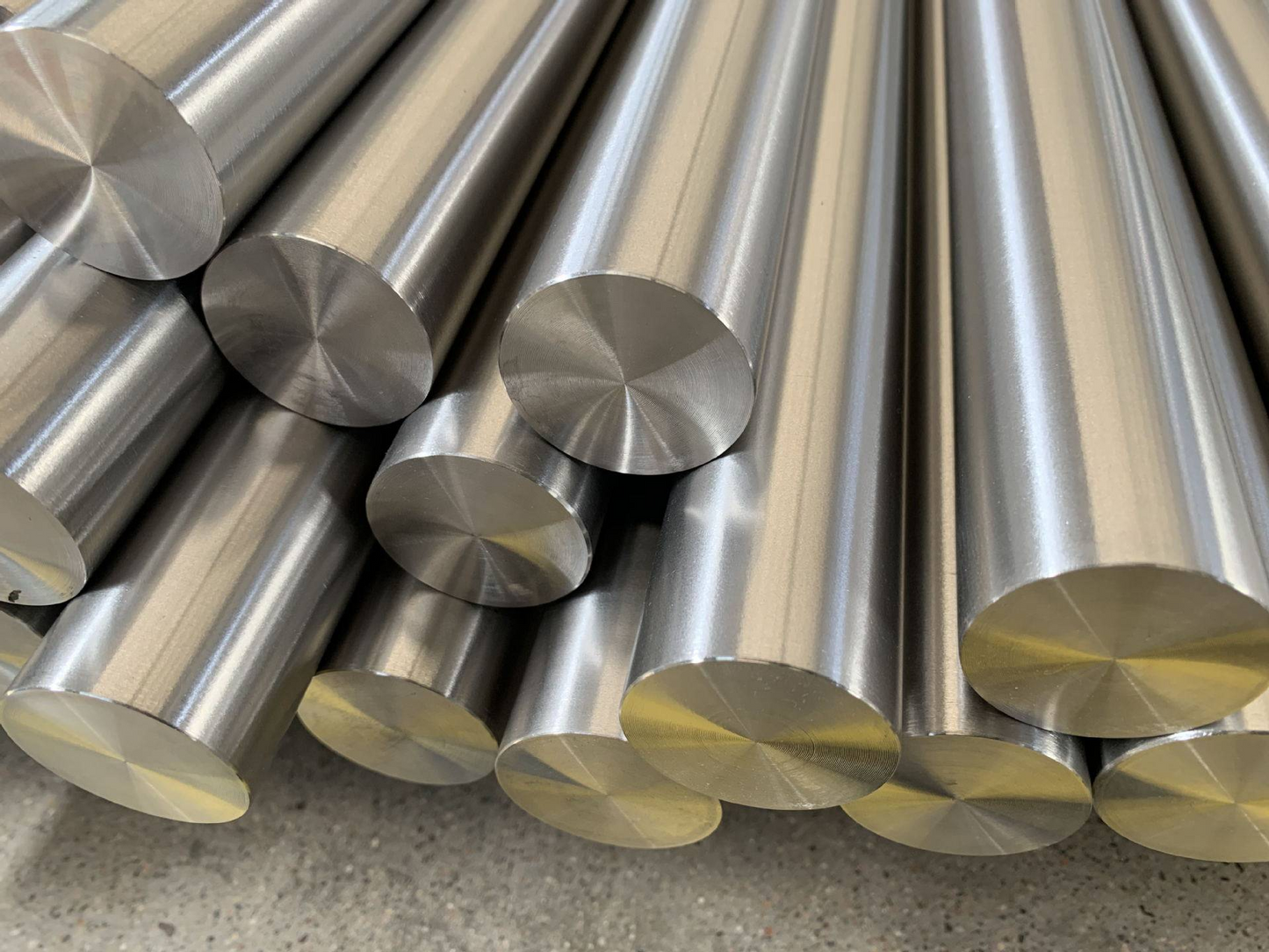

Product Overview

Metallurgical Characteristics

UNS N07750 is a precipitation-hardened nickel-chromium superalloy strengthened by gamma-prime (Ni3(Al,Ti)) precipitates. The alloy exhibits exceptional high-temperature strength retention, excellent oxidation resistance, and superior creep-rupture properties up to 700°C. The controlled addition of aluminum, titanium, and niobium provides optimal precipitation hardening response.

Heat Treatment Process

MetalZenith employs precise heat treatment cycles including solution annealing at 1095°C followed by controlled cooling and aging at 704°C for 20 hours. This process optimizes gamma-prime precipitation size and distribution, ensuring consistent mechanical properties and dimensional stability. Our computer-controlled furnaces maintain temperature uniformity within ±5°C.

Manufacturing Process

Production begins with vacuum induction melting (VIM) using high-purity raw materials, followed by vacuum arc remelting (VAR) for enhanced cleanliness. Hot working is performed within the temperature range of 1010-1175°C, with careful control of reduction ratios to achieve optimal grain structure. Cold working and intermediate annealing cycles are employed for specific product forms.

Quality Standards & Testing

All material undergoes comprehensive testing including chemical analysis by optical emission spectroscopy, mechanical property verification per ASTM standards, microstructural examination, and non-destructive testing. Ultrasonic inspection ensures internal soundness, while surface quality is verified through visual and penetrant testing. Complete material traceability is maintained from melt to final product delivery.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.08 max |

| Manganese (Mn) | 1.00 max |

| Silicon (Si) | 0.50 max |

| Phosphorus (P) | 0.015 max |

| Sulfur (S) | 0.015 max |

| Chromium (Cr) | 14.0 - 17.0 |

| Nickel (Ni) | 70.0 min |

| Iron (Fe) | 5.0 - 9.0 |

| Aluminum (Al) | 0.40 - 1.00 |

| Titanium (Ti) | 2.25 - 2.75 |

| Niobium (Nb) | 0.70 - 1.20 |

| Copper (Cu) | 0.50 max |

⚙️ Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength (Room Temperature) | 1275 MPa min |

| Yield Strength (0.2% Offset) | 1035 MPa min |

| Elongation in 50mm | 15% min |

| Reduction of Area | 15% min |

| Hardness (Rockwell C) | 35-45 HRC |

| Impact Strength (Charpy V-notch) | 41 J min |

| Fatigue Strength (10&sup7; cycles) | 620 MPa |

| Creep Rupture (649°C, 100 hrs) | 690 MPa |

| Young's Modulus | 214 GPa |

| Shear Modulus | 85 GPa |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density | 8.25 g/cm³ |

| Melting Point | 1393-1430°C |

| Thermal Conductivity (20°C) | 11.2 W/m·K |

| Thermal Conductivity (649°C) | 19.5 W/m·K |

| Thermal Expansion (20-100°C) | 11.2×10-6/K |

| Thermal Expansion (20-649°C) | 13.3×10-6/K |

| Specific Heat (20°C) | 435 J/kg·K |

| Electrical Resistivity (20°C) | 1.18 µΩ·m |

| Magnetic Permeability | 1.004 (slightly magnetic) |

| Curie Temperature | -73°C |

📏 Product Specifications

| Specification | Available Options |

|---|---|

| Product Forms | Round bar, flat bar, sheet, plate, tube, pipe, wire, forging stock |

| Round Bar Diameter | 6mm - 300mm |

| Sheet Thickness | 0.5mm - 6mm |

| Plate Thickness | 6mm - 100mm |

| Tube OD Range | 6mm - 219mm |

| Standards Compliance | ASTM B637, AMS 5542, AMS 5667, UNS N07750 |

| Surface Finish | Hot rolled, cold drawn, pickled, polished, machined |

| Dimensional Tolerance | ±0.1mm to ±0.5mm (depending on form and size) |

| Length Options | Standard lengths 3m, 6m, 12m or cut to length |

| Heat Treatment Condition | Solution annealed, aged, or customer specified |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing UNS N07750

Advanced Vacuum Melting Technology

MetalZenith utilizes cutting-edge vacuum induction melting (VIM) and vacuum arc remelting (VAR) processes to achieve exceptional material purity and chemical homogeneity. Our controlled atmosphere melting eliminates inclusions and ensures consistent gamma-prime precipitation for optimal high-temperature performance.

Precision Heat Treatment Control

Our computer-controlled heat treatment facilities provide precise temperature and time control for solution annealing and aging processes. This ensures optimal precipitation hardening, consistent mechanical properties, and dimensional stability across all product forms and sizes.

Comprehensive Testing & Certification

Every batch undergoes rigorous quality control including chemical analysis, mechanical testing, and microstructural examination. Our AS9100D and NADCAP certifications ensure compliance with aerospace standards, while complete material traceability supports critical application requirements.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications