20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

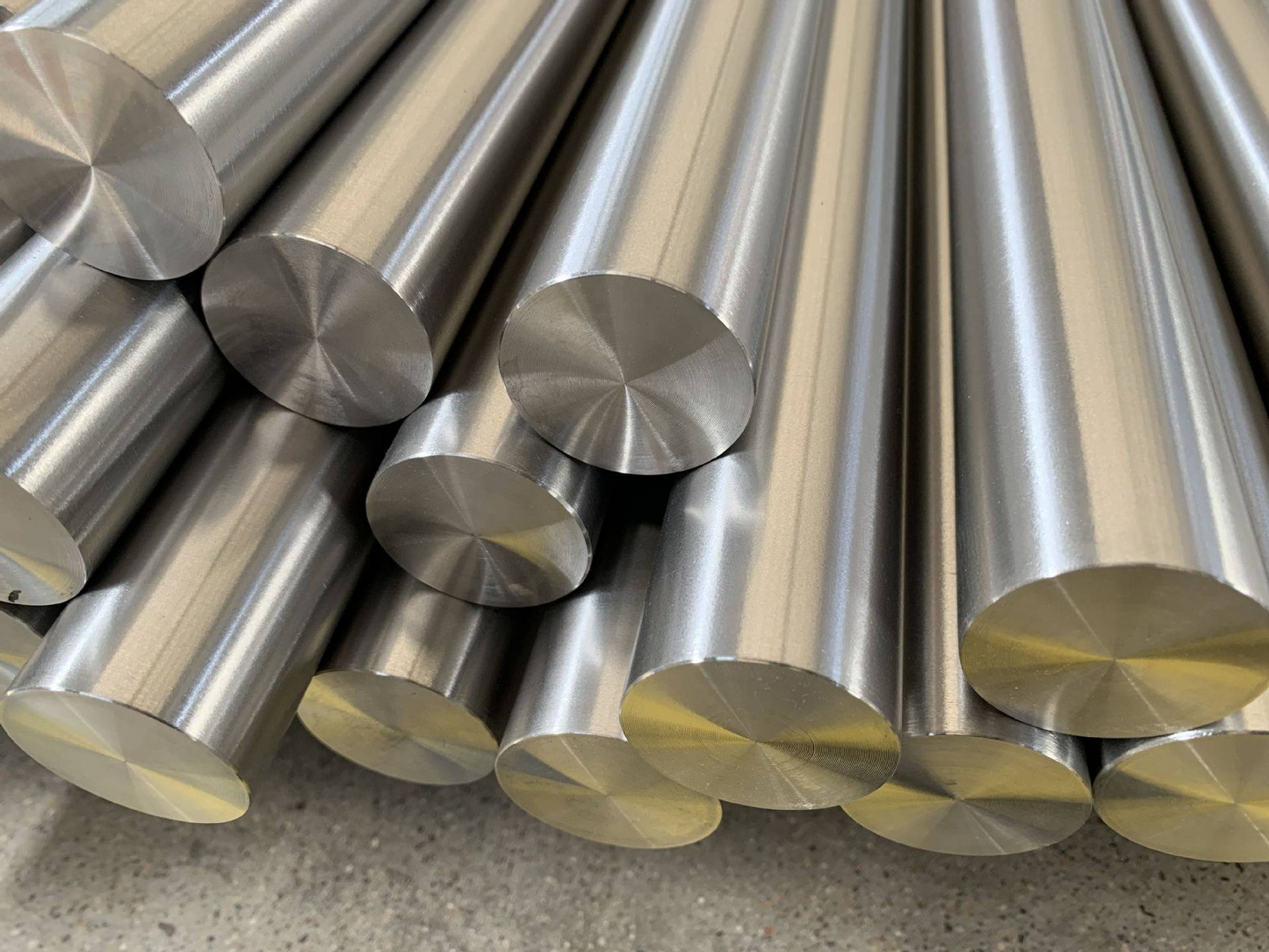

Product Overview

Metallurgical Characteristics

FH36 is a normalized fine-grain structural steel with a predominantly ferritic-pearlitic microstructure. The controlled addition of microalloying elements such as niobium and vanadium promotes grain refinement through precipitation strengthening, resulting in enhanced strength and toughness. The low carbon equivalent ensures excellent weldability while maintaining superior mechanical properties.

Heat Treatment Process

MetalZenith employs controlled normalizing heat treatment at temperatures between 900-950°C, followed by air cooling to achieve optimal microstructural refinement. This process eliminates residual stresses, homogenizes the microstructure, and ensures consistent mechanical properties throughout the material cross-section. Optional stress relief annealing at 580-650°C may be applied for specific applications.

Manufacturing Process

Our advanced steelmaking process begins with electric arc furnace melting followed by ladle refining and vacuum degassing to achieve ultra-low sulfur and phosphorus content. Continuous casting produces high-quality billets which undergo thermomechanical controlled processing (TMCP) with precise rolling schedules and controlled cooling rates to optimize grain structure and mechanical properties.

Quality Standards & Testing

All FH36 steel products undergo comprehensive quality testing including chemical analysis by optical emission spectroscopy, mechanical property verification through tensile and impact testing, ultrasonic testing for internal soundness, and dimensional inspection. MetalZenith maintains ISO 9001:2015 certification and complies with major international marine classification society requirements including ABS, DNV-GL, Lloyd's Register, and Bureau Veritas standards.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤ 0.18 |

| Manganese (Mn) | 0.90 - 1.60 |

| Silicon (Si) | 0.10 - 0.50 |

| Phosphorus (P) | ≤ 0.025 |

| Sulfur (S) | ≤ 0.025 |

| Chromium (Cr) | ≤ 0.20 |

| Nickel (Ni) | ≤ 0.40 |

| Molybdenum (Mo) | ≤ 0.08 |

| Copper (Cu) | ≤ 0.35 |

| Aluminum (Al) | ≥ 0.015 |

| Niobium (Nb) | 0.02 - 0.05 |

| Vanadium (V) | 0.05 - 0.10 |

| Titanium (Ti) | ≤ 0.02 |

⚙️ Mechanical Properties

| Property | Value |

|---|---|

| Yield Strength (ReH) | 355 - 490 MPa |

| Tensile Strength (Rm) | 490 - 630 MPa |

| Elongation (A5) | ≥ 22% |

| Impact Energy (KV) at -40°C | ≥ 34 J |

| Impact Energy (KV) at -60°C | ≥ 27 J |

| Brinell Hardness (HB) | 150 - 250 |

| Young's Modulus | 210 GPa |

| Poisson's Ratio | 0.30 |

| Fatigue Limit (107 cycles) | 245 MPa |

| Fracture Toughness (KIC) | 150 MPa·m1/2 |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density | 7.85 g/cm³ |

| Melting Point | 1510°C |

| Thermal Conductivity (20°C) | 54 W/m·K |

| Thermal Expansion Coefficient (20-100°C) | 12×10-6/K |

| Specific Heat Capacity | 500 J/kg·K |

| Electrical Resistivity (20°C) | 0.16 µΩ·m |

| Magnetic Permeability | Ferromagnetic |

| Curie Temperature | 770°C |

| Thermal Diffusivity | 13.8 mm²/s |

📏 Product Specifications

| Specification | Available Options |

|---|---|

| Product Forms | Plates, Sheets, Bars, Sections, Forgings |

| Plate Thickness | 6 - 150 mm |

| Sheet Thickness | 1.5 - 6 mm |

| Width Range | 1000 - 4000 mm |

| Length Range | 2000 - 18000 mm |

| Standards | EN 10225, ABS, DNV, LR, BV, NK |

| Surface Finish | Hot Rolled, Normalized, Shot Blasted |

| Edge Condition | Mill Edge, Trimmed Edge, Flame Cut |

| Thickness Tolerance | ±0.3 mm (6-40mm), ±0.5 mm (>40mm) |

| Width Tolerance | ±5 mm |

| Length Tolerance | ±10 mm |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing FH36

Advanced Controlled Rolling Technology

MetalZenith employs sophisticated thermomechanical controlled processing (TMCP) with precise temperature control and rolling schedules to achieve optimal grain refinement and superior mechanical properties in FH36 steel, ensuring consistent strength and toughness throughout the material thickness.

Comprehensive Marine Environment Testing

Our dedicated marine steel testing facility conducts extensive corrosion resistance testing, low-temperature impact testing, and fatigue analysis to guarantee FH36 steel performance in harsh offshore conditions, backed by full traceability and certification documentation.

Global Supply Chain & Custom Solutions

MetalZenith offers flexible supply solutions with strategic inventory locations worldwide, custom cutting and processing services, and technical support for specific offshore project requirements, ensuring timely delivery and optimal material utilization for marine construction projects.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications