20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

Product Overview

Metallurgical Characteristics

EN L450 steel features a fine-grained ferrite-pearlite microstructure achieved through controlled thermomechanical processing. The addition of microalloying elements such as niobium and vanadium provides precipitation strengthening and grain refinement, resulting in excellent strength-toughness balance essential for pipeline applications.

Heat Treatment Process

MetalZenith employs advanced controlled rolling followed by accelerated cooling (TMCP) to optimize the microstructure of EN L450 steel. The process involves:

- Reheating to 1150-1250°C for austenite formation

- Controlled rolling in the temperature range of 850-950°C

- Accelerated cooling at rates of 5-30°C/s to 500-600°C

- Air cooling to ambient temperature

Manufacturing Process Excellence

Our state-of-the-art production facility utilizes electric arc furnace steelmaking followed by ladle refining and continuous casting. The hot rolling process incorporates advanced process control systems to ensure consistent mechanical properties and dimensional accuracy. Seamless pipes are manufactured using the Mannesmann piercing process, while welded pipes employ high-frequency induction welding technology.

Quality Standards Compliance

EN L450 steel manufactured by MetalZenith complies with multiple international standards including EN 10208-2, API 5L PSL2, and ISO 3183. Our quality management system is certified to ISO 9001:2015, ensuring consistent product quality and traceability. Each batch undergoes comprehensive testing including chemical analysis, mechanical testing, non-destructive examination, and hydrostatic pressure testing to guarantee performance reliability in critical pipeline applications.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤ 0.16 |

| Manganese (Mn) | 1.40 - 1.65 |

| Silicon (Si) | 0.15 - 0.45 |

| Phosphorus (P) | ≤ 0.025 |

| Sulfur (S) | ≤ 0.015 |

| Chromium (Cr) | ≤ 0.30 |

| Nickel (Ni) | ≤ 0.30 |

| Molybdenum (Mo) | ≤ 0.15 |

| Copper (Cu) | ≤ 0.35 |

| Niobium (Nb) | 0.02 - 0.05 |

| Vanadium (V) | ≤ 0.06 |

| Titanium (Ti) | ≤ 0.04 |

| Aluminum (Al) | ≥ 0.015 |

| Nitrogen (N) | ≤ 0.012 |

⚙️ Mechanical Properties

| Property | Value |

|---|---|

| Yield Strength (Rp0.2) | 450 - 570 MPa |

| Tensile Strength (Rm) | 535 - 760 MPa |

| Elongation (A5) | ≥ 22% |

| Yield to Tensile Ratio | ≤ 0.85 |

| Charpy V-Notch Impact Energy (0°C) | ≥ 40 J |

| Charpy V-Notch Impact Energy (-20°C) | ≥ 27 J |

| Hardness (HV10) | 200 - 280 |

| Fatigue Limit (107 cycles) | 240 MPa |

| Fracture Toughness (KIC) | 150 - 200 MPa·m1/2 |

| Young's Modulus | 210 GPa |

| Poisson's Ratio | 0.30 |

| Shear Modulus | 80 GPa |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density | 7.85 g/cm³ |

| Melting Point | 1510°C |

| Thermal Conductivity (20°C) | 54 W/m·K |

| Thermal Expansion Coefficient (20-100°C) | 12×10-6/K |

| Specific Heat Capacity | 500 J/kg·K |

| Electrical Resistivity (20°C) | 0.16 µΩ·m |

| Magnetic Permeability | Ferromagnetic |

| Curie Temperature | 770°C |

| Thermal Diffusivity | 13.8 mm²/s |

| Emissivity (oxidized surface) | 0.79 |

| Sound Velocity (longitudinal) | 5900 m/s |

| Bulk Modulus | 175 GPa |

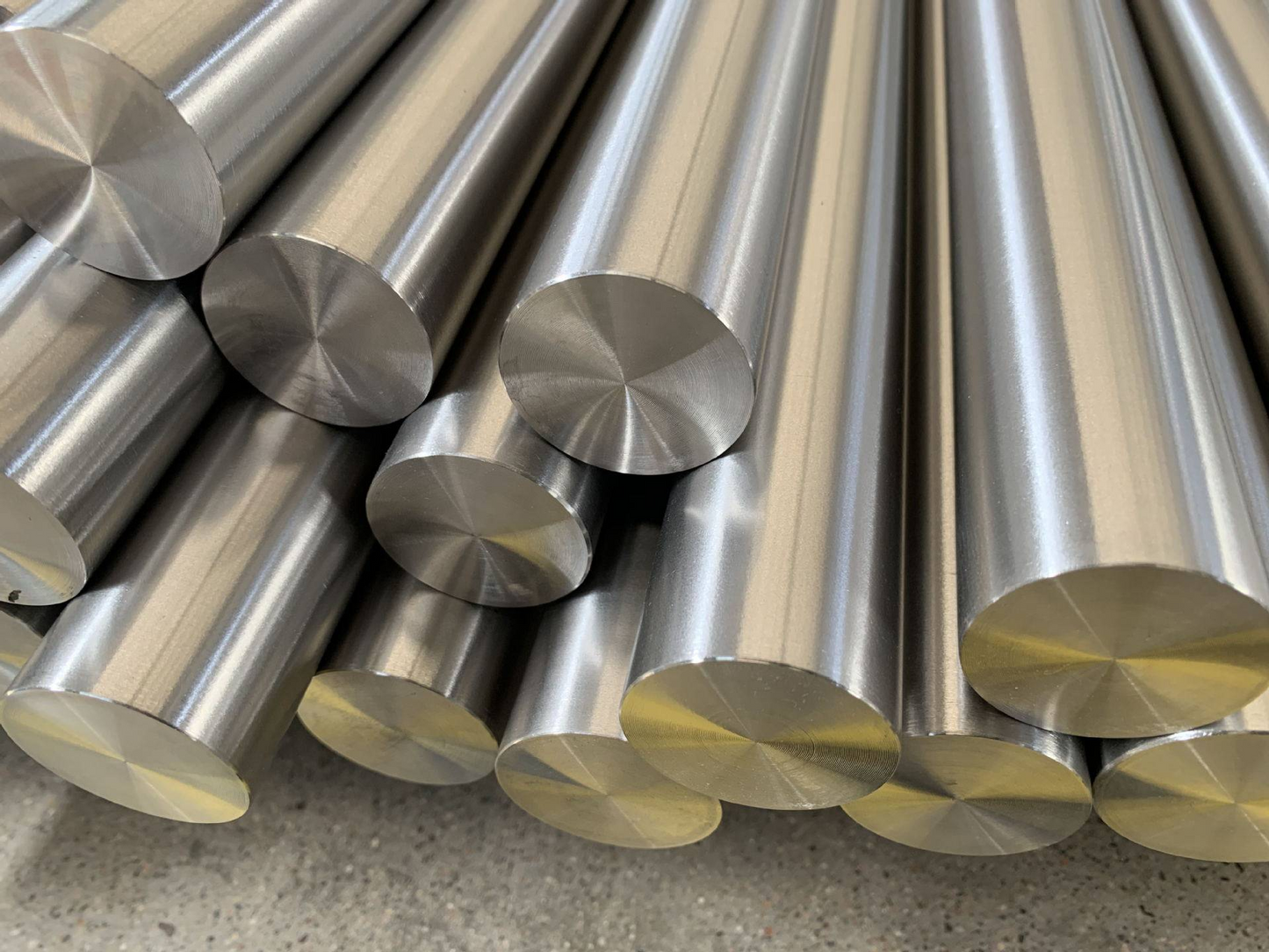

📏 Product Specifications

| Specification | Details |

|---|---|

| Available Forms | Seamless Pipes, Welded Pipes, Plates, Sheets, Coils, Bars |

| Pipe Diameter Range | 6.35 - 1422 mm (1/4" - 56") |

| Wall Thickness Range | 1.65 - 80 mm |

| Plate Thickness Range | 6 - 150 mm |

| Standard Lengths | 6 - 18 meters (custom lengths available) |

| Manufacturing Standards | EN 10208-2, API 5L, ISO 3183, ASTM A106 |

| Surface Finishes | Black, Pickled, Shot Blasted, Epoxy Coated |

| End Preparations | Plain End, Beveled End, Threaded, Socket Weld |

| Dimensional Tolerance | ±1% on OD, ±10% on WT (API 5L standards) |

| Testing Requirements | Hydrostatic, Ultrasonic, Eddy Current, Radiographic |

| Certifications | Mill Test Certificate, Third Party Inspection, PED 2014/68/EU |

| Packaging | Bundled, Wooden Cases, Steel Frames, Export Packaging |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing EN L450

Advanced Thermomechanical Processing

MetalZenith employs cutting-edge controlled rolling and accelerated cooling technology to achieve optimal microstructure refinement in EN L450 steel, ensuring superior mechanical properties and enhanced pipeline performance in demanding environments.

Comprehensive Quality Control System

Our state-of-the-art testing facilities feature automated ultrasonic inspection, advanced mechanical testing equipment, and precision chemical analysis systems, ensuring every batch of EN L450 steel meets or exceeds international pipeline standards.

Custom Engineering Solutions

MetalZenith provides tailored EN L450 steel solutions with custom dimensions, surface treatments, and mechanical properties to meet specific project requirements, backed by our global supply chain and technical support services.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications