20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

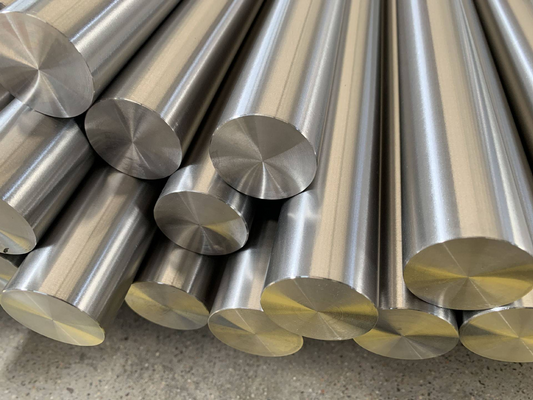

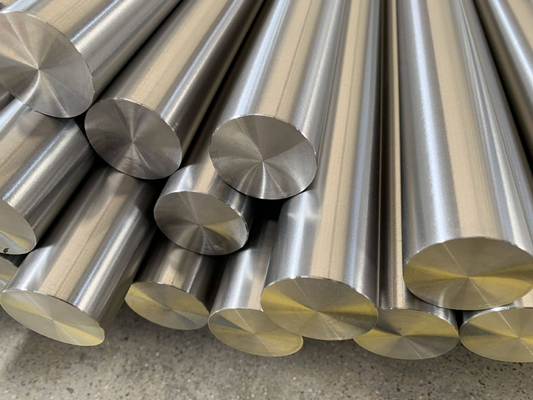

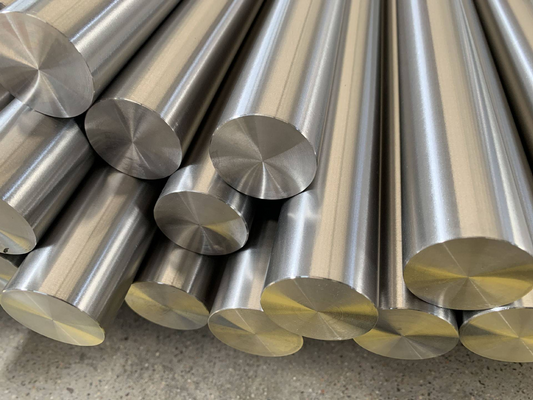

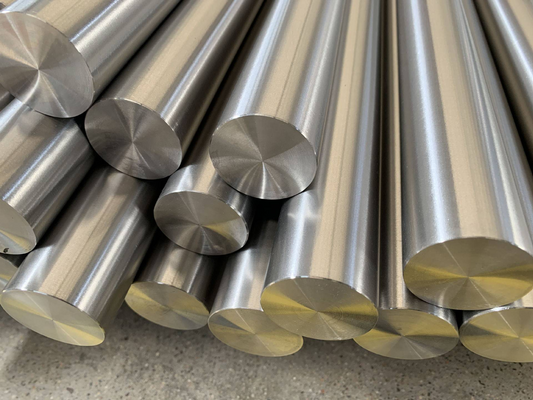

Product Overview

Metallurgical Characteristics

P91 steel features a tempered martensitic microstructure with fine carbide precipitates of M23C6 and MX types. The controlled addition of vanadium and niobium promotes precipitation strengthening and grain boundary stabilization, while the 9% chromium content provides excellent oxidation resistance. The microstructure exhibits exceptional thermal stability with minimal coarsening during long-term high-temperature exposure.

Heat Treatment Process

MetalZenith employs a precise heat treatment sequence including austenitizing at 1040-1080°C followed by air cooling, then tempering at 730-780°C with controlled cooling rates. This process ensures optimal carbide precipitation and achieves the required balance between strength, toughness, and creep resistance for high-temperature service applications.

Manufacturing Excellence

Our advanced manufacturing process includes vacuum induction melting for superior cleanliness, controlled forging with optimized reduction ratios, and precision machining capabilities. MetalZenith maintains strict control over grain size, inclusion content, and chemical homogeneity to ensure consistent high-temperature performance and reliability.

Specialized Quality Testing

MetalZenith conducts comprehensive testing protocols including 1000-hour creep rupture testing at design temperatures, cyclic oxidation testing up to 650°C, thermal shock resistance evaluation, and long-term microstructural stability analysis using advanced electron microscopy techniques. These tests ensure material integrity throughout the expected service life.

Application Engineering

For gas turbine applications, P91 provides excellent thermal fatigue resistance and dimensional stability. In boiler tube applications, the material offers superior steam oxidation resistance and creep strength. For petrochemical vessels, P91 delivers exceptional resistance to high-temperature corrosion and hydrogen attack. In aerospace applications, the material provides reliable performance under extreme thermal cycling conditions.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.08 - 0.12 |

| Chromium (Cr) | 8.00 - 9.50 |

| Molybdenum (Mo) | 0.85 - 1.05 |

| Vanadium (V) | 0.18 - 0.25 |

| Niobium (Nb) | 0.06 - 0.10 |

| Manganese (Mn) | 0.30 - 0.60 |

| Silicon (Si) | 0.20 - 0.50 |

| Nitrogen (N) | 0.030 - 0.070 |

⚙️ Mechanical Properties

| Property | Value |

|---|---|

| Yield Strength at 20°C (MPa) | ≥ 415 |

| High Temperature Yield Strength at 600°C (MPa) | ≥ 200 |

| Creep Rupture Strength 100,000h at 600°C (MPa) | ≥ 100 |

| High Temperature Fatigue Strength at 550°C (MPa) | ≥ 280 |

| Thermal Fatigue Resistance (cycles) | ≥ 10,000 |

| Oxidation Rate at 650°C (mg/cm2) | ≤ 0.5 |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density (g/cm3) | 7.75 |

| Melting Point (°C) | 1480 - 1520 |

| Thermal Conductivity at 600°C (W/m·K) | 28.5 |

| Thermal Expansion at 600°C (×10??/K) | 13.2 |

| Elastic Modulus at 600°C (GPa) | 165 |

| Specific Heat Capacity (J/kg·K) | 460 |

📏 Product Specifications

| Specification | Details |

|---|---|

| Available Forms | Seamless Tubes, Plates, Forgings, Bars, Fittings |

| Tube Wall Thickness | 3 - 50mm |

| Outer Diameter Range | 10 - 600mm |

| Plate Thickness Range | 8 - 150mm |

| Standards Compliance | ASTM A335 P91, ASME SA-335, EN 10216-2 |

| Heat Treatment Condition | Normalized and Tempered |

| Service Temperature Range | Up to 650°C |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing P91 Steel

Advanced Vacuum Melting & Heat Treatment

MetalZenith utilizes vacuum induction melting followed by precise normalizing and tempering processes with controlled cooling rates to achieve optimal martensitic microstructure. Our advanced heat treatment protocols ensure uniform carbide precipitation and enhanced creep resistance properties essential for high-temperature service.

Comprehensive High-Temperature Testing

MetalZenith conducts extensive testing including 1000-hour creep rupture testing at 600°C, cyclic oxidation resistance evaluation up to 650°C, thermal fatigue testing, and long-term microstructural stability analysis. Our rigorous testing protocols ensure consistent performance in demanding high-temperature environments.

Custom High-Temperature Solutions

MetalZenith provides tailored P91 steel solutions with custom heat treatment schedules, specialized forming processes, and comprehensive technical support. Our metallurgical experts work closely with customers to optimize material properties for specific high-temperature applications and service conditions.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications