20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

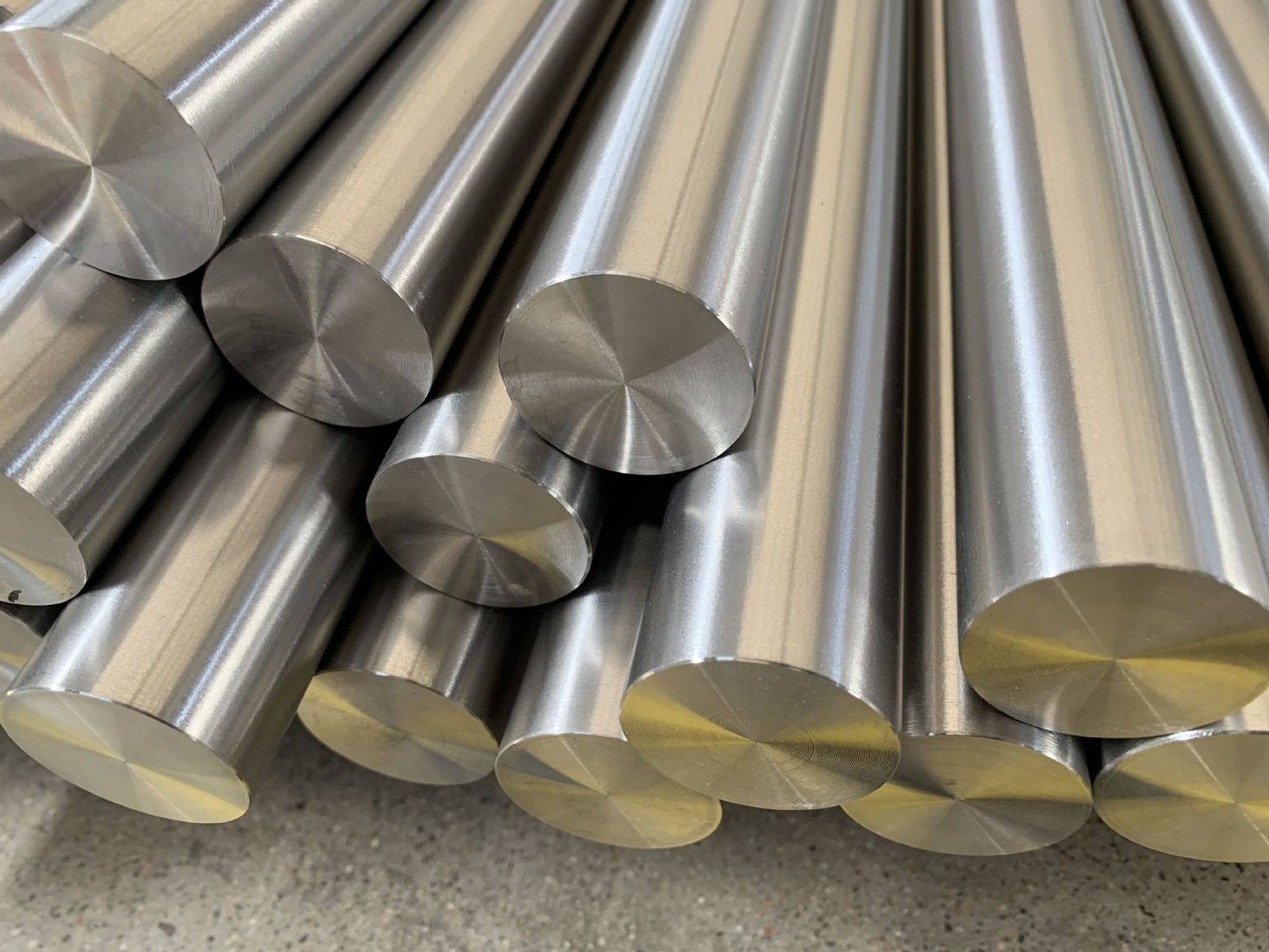

Product Overview

Metallurgical Characteristics

EN 1.4016 is a ferritic stainless steel with a body-centered cubic (BCC) crystal structure. The chromium content of 16-18% forms a protective passive oxide layer, providing excellent corrosion resistance in atmospheric and mildly corrosive environments. The ferritic structure makes this grade magnetic and non-hardenable by heat treatment, offering good formability and weldability characteristics.

Heat Treatment Process

MetalZenith employs controlled annealing processes at 750-850°C followed by air cooling or controlled cooling to achieve optimal grain structure and mechanical properties. Solution annealing at 850-950°C may be applied for stress relief and maximum corrosion resistance. Our advanced furnace technology ensures uniform heating and precise temperature control throughout the material cross-section.

Manufacturing Process

Our production process begins with electric arc furnace melting followed by AOD refining for precise chemistry control. Continuous casting produces high-quality billets, which undergo hot rolling, cold rolling, and annealing cycles. MetalZenith's advanced rolling mills achieve excellent surface quality and dimensional accuracy. Final processing includes pickling, passivation, and surface finishing according to customer specifications.

Quality Standards & Testing

Every batch undergoes comprehensive testing including chemical analysis by optical emission spectroscopy, mechanical testing per ASTM standards, intergranular corrosion testing (ASTM A262), and dimensional inspection. MetalZenith maintains full traceability from raw materials to finished products, ensuring compliance with international quality standards and customer specifications.

Corrosion Resistance & Performance

EN 1.4016 exhibits excellent resistance to atmospheric corrosion, water, and mild chemical environments. The material demonstrates superior performance in automotive exhaust applications, kitchen equipment, and architectural applications. MetalZenith's optimized chemistry and processing ensure maximum corrosion resistance while maintaining excellent formability for complex forming operations.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤ 0.08 |

| Silicon (Si) | ≤ 1.00 |

| Manganese (Mn) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.040 |

| Sulfur (S) | ≤ 0.015 |

| Chromium (Cr) | 16.0 - 18.0 |

| Nickel (Ni) | ≤ 0.75 |

| Molybdenum (Mo) | ≤ 0.20 |

| Titanium (Ti) | ≤ 0.20 |

| Aluminum (Al) | ≤ 0.10 |

| Nitrogen (N) | ≤ 0.030 |

| Iron (Fe) | Balance |

⚙️ Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength (Rm) | 450 - 630 MPa |

| Yield Strength (Rp0.2) | ≥ 280 MPa |

| Elongation (A50) | ≥ 22% |

| Elongation (A80) | ≥ 20% |

| Hardness (HRB) | ≤ 88 |

| Hardness (HV) | 150 - 220 |

| Impact Energy (KV at 20°C) | ≥ 40 J |

| Fatigue Limit (10^7 cycles) | 200 - 250 MPa |

| Young's Modulus | 220 GPa |

| Shear Modulus | 81 GPa |

| Poisson's Ratio | 0.27 - 0.30 |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density | 7.70 g/cm³ |

| Melting Point | 1425 - 1510°C |

| Thermal Conductivity (20°C) | 25.1 W/m·K |

| Thermal Conductivity (100°C) | 26.3 W/m·K |

| Thermal Expansion (20-100°C) | 10.4×10-6/K |

| Thermal Expansion (20-300°C) | 11.0×10-6/K |

| Specific Heat Capacity | 460 J/kg·K |

| Electrical Resistivity (20°C) | 0.60 µΩ·m |

| Magnetic Permeability | Ferromagnetic |

| Curie Temperature | 770°C |

| Thermal Diffusivity (20°C) | 7.1×10-6 m²/s |

📏 Product Specifications

| Specification | Available Options |

|---|---|

| Product Forms | Sheets, Plates, Strips, Coils, Bars, Rods, Tubes, Pipes |

| Sheet Thickness | 0.3 - 6.0 mm |

| Plate Thickness | 6.0 - 100 mm |

| Strip Width | 10 - 600 mm |

| Coil Width | 1000 - 2000 mm |

| Bar Diameter | 6 - 300 mm |

| Tube Outer Diameter | 6 - 219 mm |

| Surface Finishes | 2B, BA, No.4, HL (Hairline), Mirror |

| Standards Compliance | EN 10088, ASTM A240, JIS G4305, GB/T 3280 |

| Dimensional Tolerance | ±0.02 - ±0.10 mm (depending on form) |

| Length Options | Standard lengths or cut to size |

| Edge Conditions | Mill edge, Slit edge, Trimmed edge |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing EN 1.4016

Advanced AOD Refining Technology

MetalZenith employs cutting-edge Argon Oxygen Decarburization (AOD) technology for precise chemical composition control and ultra-low carbon content, ensuring superior corrosion resistance and formability in EN 1.4016 production.

Comprehensive Quality Control System

Our ISO 9001:2015 certified quality management system includes advanced spectroscopic analysis, mechanical testing, and corrosion testing facilities, guaranteeing consistent material properties and performance standards for every batch.

Global Supply Chain & Customization

MetalZenith offers flexible customization options including specific dimensions, surface finishes, and packaging requirements, supported by our global distribution network ensuring timely delivery worldwide with complete traceability.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications