20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

Product Overview

Metallurgical Characteristics

ASTM A514 Grade S is a quenched and tempered high-strength low-alloy steel featuring a fine-grained martensitic microstructure with tempered carbides. The controlled addition of chromium, molybdenum, and nickel provides enhanced hardenability and strength, while maintaining excellent toughness and weldability characteristics.

Heat Treatment Process

MetalZenith employs a precise austenitizing treatment at 900-950°C followed by water quenching to achieve the desired martensitic structure. Subsequent tempering at 580-650°C optimizes the balance between strength and toughness while relieving internal stresses. Our computer-controlled heat treatment ensures uniform properties throughout the material cross-section.

Manufacturing Process

Production begins with electric arc furnace melting using premium scrap and alloy additions, followed by ladle refining and vacuum degassing to achieve optimal cleanliness. Continuous casting produces high-quality billets which are hot rolled to final dimensions. The quench and temper process is performed in our state-of-the-art heat treatment facilities with precise atmosphere control.

Quality Standards & Testing

Every production lot undergoes comprehensive testing including chemical analysis by optical emission spectroscopy, tensile and impact testing per ASTM standards, hardness verification, and ultrasonic inspection for internal soundness. Mill test certificates provide complete traceability and compliance documentation. Additional testing such as fatigue, fracture toughness, and weldability testing is available upon request.

Welding Considerations

ASTM A514 Grade S exhibits excellent weldability when proper procedures are followed. Preheating to 150-200°C is recommended for thick sections, with interpass temperature control below 250°C. Post-weld stress relief may be required for critical applications. MetalZenith provides comprehensive welding procedure specifications and technical support for optimal joint performance.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.15-0.21 |

| Manganese (Mn) | 0.70-1.00 |

| Silicon (Si) | 0.20-0.35 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.035 |

| Chromium (Cr) | 0.50-0.80 |

| Nickel (Ni) | 0.30-0.70 |

| Molybdenum (Mo) | 0.18-0.28 |

| Copper (Cu) | ≤ 0.35 |

| Aluminum (Al) | 0.020-0.050 |

| Nitrogen (N) | ≤ 0.015 |

| Vanadium (V) | 0.03-0.08 |

⚙️ Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 760-895 MPa (110-130 ksi) |

| Yield Strength (0.2% offset) | ≥ 690 MPa (100 ksi) |

| Elongation in 50mm | ≥ 18% |

| Reduction of Area | ≥ 45% |

| Hardness (Brinell) | 235-293 HB |

| Impact Energy (Charpy V-notch at 0°C) | ≥ 34 J (25 ft-lbs) |

| Fatigue Limit (10^7 cycles) | 380 MPa |

| Modulus of Elasticity | 200 GPa |

| Poisson's Ratio | 0.27-0.30 |

| Shear Modulus | 80 GPa |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density | 7.85 g/cm³ |

| Melting Point | 1425-1470°C |

| Thermal Conductivity (at 20°C) | 42 W/m·K |

| Thermal Expansion Coefficient (20-100°C) | 12.5×10-6/K |

| Specific Heat Capacity | 460 J/kg·K |

| Electrical Resistivity | 0.20 µΩ·m |

| Magnetic Permeability | Ferromagnetic |

| Curie Temperature | 770°C |

| Thermal Diffusivity | 11.6 mm²/s |

📏 Product Specifications

| Specification | Details |

|---|---|

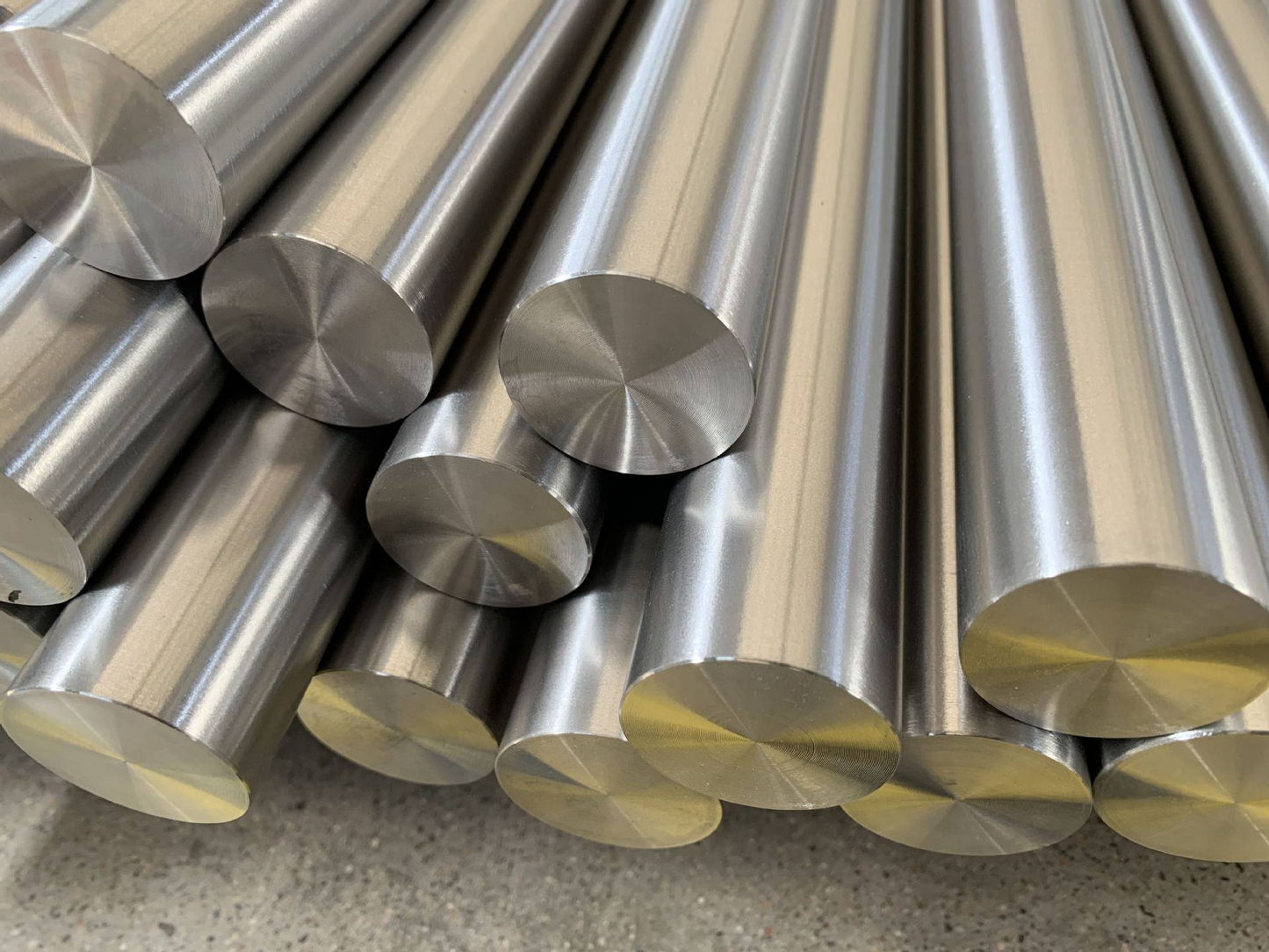

| Available Forms | Plates, Sheets, Bars, Structural Shapes |

| Plate Thickness Range | 6-150mm (0.25-6 inches) |

| Sheet Thickness Range | 1.5-6mm (0.06-0.25 inches) |

| Bar Diameter Range | 10-300mm (0.4-12 inches) |

| Standard Compliance | ASTM A514, ASTM A709 Grade 100 |

| Surface Finish | Hot Rolled, Pickled, Shot Blasted |

| Edge Condition | Mill Edge, Sheared, Flame Cut, Machined |

| Dimensional Tolerance | ASTM A6/A6M Standard |

| Flatness Tolerance | ≤ 5mm/m |

| Length Range | Up to 18m (custom lengths available) |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing ASTM A514 Grade S

Advanced Heat Treatment Technology

MetalZenith employs precision-controlled quenching and tempering processes with computer-monitored temperature profiles, ensuring consistent mechanical properties and optimal microstructure throughout the material thickness for superior performance.

Comprehensive Quality Control System

Our integrated quality management system includes real-time chemical analysis, automated mechanical testing, ultrasonic inspection, and dimensional verification, guaranteeing every product meets or exceeds ASTM A514 Grade S specifications.

Custom Processing & Global Supply

MetalZenith offers extensive customization capabilities including precision cutting, forming, and surface treatments, backed by our global distribution network ensuring timely delivery of tailored solutions worldwide.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications