20 Jahre Erfahrung | 1000+ Markenpartner | Vollständige Anpassung

Wir haben 20 Jahre Branchenerfahrung, haben mit über 1.000 Marken zusammengearbeitet und unterstützen alle Anpassungsbedürfnisse.

Technical Specifications

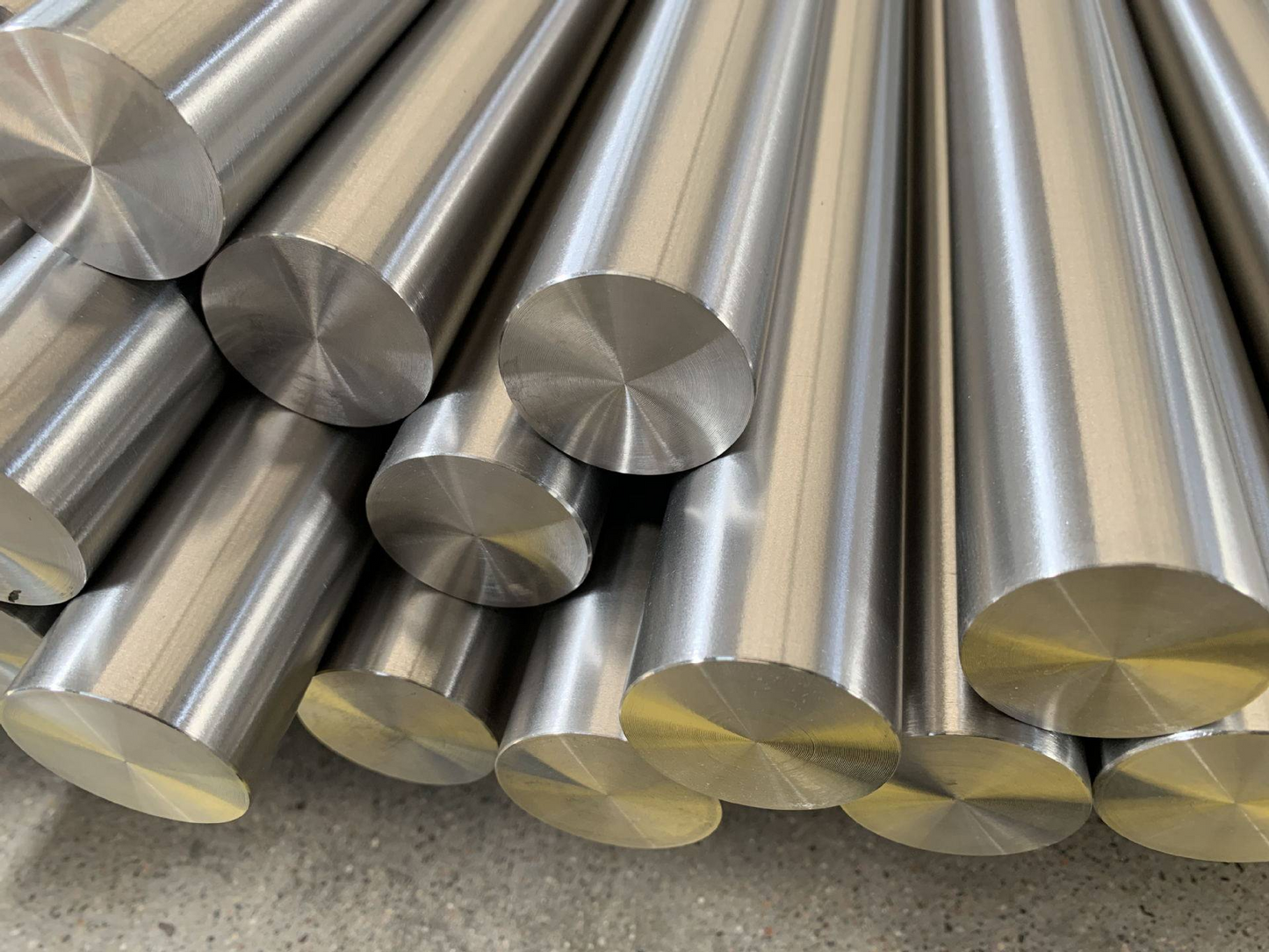

Product Overview

Metallurgische Eigenschaften

AISI 440C ist ein hochkohlenstoffhaltiger martensitischer Edelstahl mit außergewöhnlicher Härte und Verschleißfestigkeit. Der hohe Kohlenstoffgehalt (0,95-1,20%) in Kombination mit Chrom (16-18%) bietet hervorragende Härtbarkeit und Korrosionsbeständigkeit. Der kontrollierte Schmelzprozess von MetalZenith gewährleistet eine gleichmäßige Karbidverteilung und eine optimale mikrostrukturelle Entwicklung.

Wärmebehandlungsprozess

MetalZenith verwendet präzise Wärmebehandlungszyklen für AISI 440C: Anlassen bei 870-900°C, gefolgt von langsamer Abkühlung, Härten bei 1010-1065°C mit Öl- oder Luftabschreckung und Vergüten bei 150-200°C für maximale Härte oder 200-300°C für verbesserte Zähigkeit. Unsere computergesteuerten Öfen gewährleisten konsistente Ergebnisse mit minimaler Verzerrung.

Herstellungsprozess

Unser Produktionsprozess beginnt mit dem Schmelzen im Lichtbogenofen, gefolgt von AOD-Raffination zur genauen Chemiekontrolle. Die sekundäre Raffination durch Pfannenmetallurgie gewährleistet einen niedrigen Einschlussgehalt. Warmwalzen, Kaltbearbeitung und präzise Bearbeitungsmöglichkeiten ermöglichen es MetalZenith, Produkte in verschiedenen Formen mit engen Maßtoleranzen zu liefern.

Qualitätsstandards & Prüfung

MetalZenith hält die Standards ASTM A276, A314, A479 und AMS 5630 ein. Umfassende Tests umfassen chemische Analysen durch optische Emissionsspektroskopie, Überprüfung der mechanischen Eigenschaften, Härteprüfungen, mikrostrukturelle Untersuchungen und Ultraschallinspektionen. Eine vollständige Materialverfolgbarkeit und Zertifizierungspakete werden mit jeder Lieferung bereitgestellt.

Korrosionsbeständigkeit & Leistung

AISI 440C bietet eine gute Korrosionsbeständigkeit in milden Umgebungen, überlegen gegenüber Kohlenstoffen, aber geringer als austenitische Edelstähle. Das Material eignet sich hervorragend für Anwendungen, die hohe Härte, Verschleißfestigkeit und moderate Korrosionsbeständigkeit erfordern. MetalZenith kann spezialisierte Oberflächenbehandlungen einschließlich Nitrieren und Beschichtung für verbesserte Leistung in anspruchsvollen Anwendungen anbieten.

🧪 Chemical Composition

| Element | Zusammensetzung (%) |

|---|---|

| Kohlenstoff (C) | 0.95 - 1.20 |

| Chrom (Cr) | 16.00 - 18.00 |

| Molybdän (Mo) | 0.75 max |

| Mangan (Mn) | 1.00 max |

| Silizium (Si) | 1.00 max |

| Phosphor (P) | 0.040 max |

| Schwefel (S) | 0.030 max |

| Nickel (Ni) | 0.60 max |

| Kupfer (Cu) | 0.50 max |

| Eisen (Fe) | Rest |

⚙️ Mechanical Properties

| Eigenschaft | Wert | Zustand |

|---|---|---|

| Zugfestigkeit | 1790 - 2070 MPa | Härtet & Temperiert |

| Streckgrenze (0,2% Offset) | 1650 - 1930 MPa | Härtet & Temperiert |

| Dehnung | 2 - 5% | Härtet & Temperiert |

| Querschnittsreduktion | 15 - 25% | Härtet & Temperiert |

| Härte (Rockwell C) | 58 - 62 HRC | Härtet & Temperiert |

| Schlagenergie (Charpy V-Kerbe) | 15 - 25 J | Raumtemperatur |

| Ermüdungsgrenze (10&sup7; Zyklen) | 800 - 900 MPa | Rotierende Biegung |

| Elastizitätsmodul | 200 GPa | Raumtemperatur |

| Poisson-Zahl | 0.27 - 0.30 | Raumtemperatur |

🔬 Physical Properties

| Eigenschaft | Wert | Temperatur |

|---|---|---|

| Dichte | 7.70 g/cm³ | 20°C |

| Schmelzpunkt | 1480 - 1530°C | - |

| Wärmeleitfähigkeit | 24.2 W/m·K | 100°C |

| Wärmeausdehnungskoeffizient | 10.2×10-6/K | 20-100°C |

| Spezifische Wärmekapazität | 460 J/kg·K | 20°C |

| Elektrische Widerstandsfähigkeit | 0.60 µΩ·m | 20°C |

| Magnetische Permeabilität | Ferromagnetisch | Härtungszustand |

| Curie-Temperatur | 760°C | - |

| Wärmediffusivität | 6.8×10-6 m²/s | 100°C |

📏 Product Specifications

| Spezifikation | Verfügbare Optionen | Standards |

|---|---|---|

| Produktformen | Runde Stangen, Flachstangen, Bleche, Platten, Rohre, Schmiedeteile | ASTM A276, A314, A479 |

| Durchmesser der Rundstange | 6mm - 300mm | ASTM A276 |

| Abmessungen der Flachstange | 10mm - 100mm Dicke, bis zu 300mm Breite | ASTM A276 |

| Blechdicke | 0.5mm - 6mm | ASTM A240 |

| Plattendicke | 6mm - 100mm | ASTM A240 |

| Oberflächenfinish | Warmgewalzt, kaltgezogen, geschliffen, poliert | Gemäß Kundenspezifikation |

| Maßtoleranz | ±0.1mm bis ±0.5mm je nach Form | ASTM-Standards |

| Länge | Bis zu 6 Meter (maßgeschneiderte Längen verfügbar) | Kundenspezifikation |

| Wärmebehandlungszustand | Geglüht, gehärtet & vergütet, spannungsarm | AMS 5630, AMS 5880 |

Lassen Sie uns Erfolg für Ihr Projekt schaffen

Professionelles Team, Premium-Produkte, Vollständiger Service - Ihr Projekterfolg ist unsere Mission

Our Advantages in Processing AISI 440C

Fortgeschrittene Vakuum-Schmelztechnologie

MetalZenith verwendet modernste Vakuum-Induktionsschmelzen (VIM) und Elektroschlacke-Umschmelzen (ESR), um ultra-reines AISI 440C mit minimalen Einschlüssen und überlegener Homogenität herzustellen. Unser kontrolliertes Atmosphärenschmelzen gewährleistet einen präzisen Kohlenstoffgehalt und eine optimale Karbidverteilung für maximale Leistung.

Präzisionswärmebehandlungssteuerung

Unsere computergestützten Wärmebehandlungsanlagen verfügen über fortschrittliche Atmosphärenkontrolle und präzise Temperaturüberwachungssysteme. Die proprietären Wärmebehandlungszyklen von MetalZenith optimieren Härte, Zähigkeit und dimensionsstabilität, während sie Restspannungen und Verformungen in AISI 440C-Komponenten minimieren.

Umfassende Tests & Anpassung

MetalZenith bietet eine vollständige Materialcharakterisierung, einschließlich mikrostruktureller Analyse, Korrosionstests und Ermüdungsbewertung. Unser Ingenieurteam bietet maßgeschneiderte Wärmebehandlungs-spezifikationen, spezialisierte Oberflächenbehandlungen und präzise Bearbeitungsdienste, um die genauen Kundenanforderungen für kritische Anwendungen zu erfüllen.

IHR VERTRAUENwürdiger STAHL

HERSTELLUNGSPARTNER

Schnellanfrage

Branchen, die wir bedienen

Professionelle Stahl-Lösungen in wichtigen Branchen

Qualifikationen & Zertifizierungen