What is Cee Channel Steel and Its Key Features

Share

Table Of Content

Table Of Content

Cee channel steel, named for its distinctive C-shaped design, is a durable yet lightweight material widely used in construction and industrial applications. Its unique shape provides strength without adding unnecessary weight, making it highly practical. Additionally, its resistance to rust ensures longevity, even in challenging environments.

The use of steel channels is becoming increasingly common in large-scale projects. This trend is driven by urban expansion and government investments in infrastructure. For instance:

- Global demand for steel is projected to reach 1.7 billion tons by 2025.

- An improving global economy is fueling the need for construction materials like steel channels.

Cee channel steel plays a crucial role in addressing these demands, offering strength and versatility across various industries.

Key Takeaways

- Cee channel steel is strong but light, perfect for building projects.

- Its special C-shape makes it strong and holds heavy weight.

- It does not rust easily, especially with a protective coating.

- This steel is useful for many things like frames and car parts.

- Cee channel steel is cheap and eco-friendly since it can be reused.

What is Cee Channel Steel?

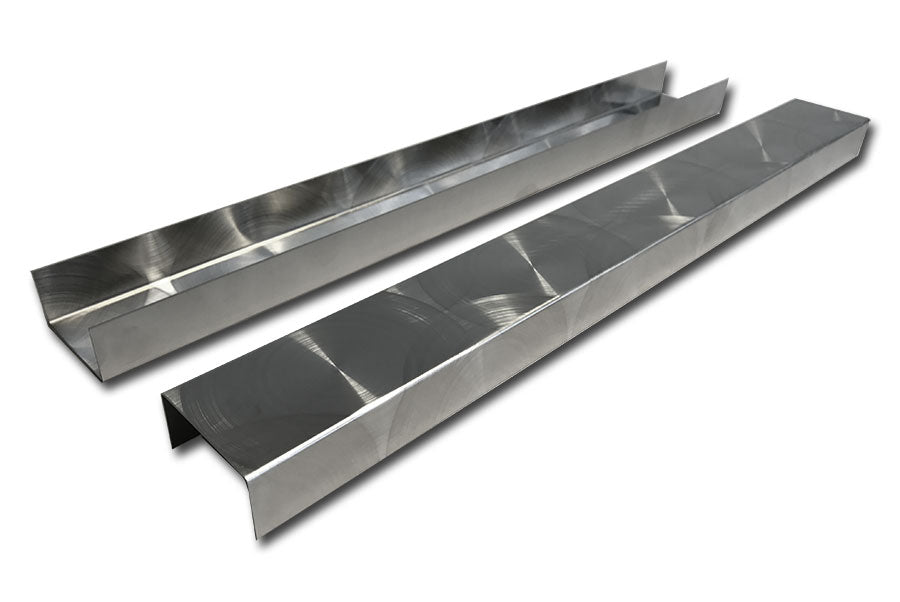

Definition and Shape

Cee channel steel is named for its C-like shape. It has three main parts: the web and two flanges. The web is the vertical part that handles pressure. The flanges are the horizontal parts that stop bending. This design makes it strong and reliable.

The size of cee channel steel changes based on its use. Below is a table showing common sizes:

| Dimension | Range | Typical Applications |

|---|---|---|

| Web Height (Depth) | 3 inches (7.6 cm) to 12 inches (30.5 cm) | Used in building beams and bridge structures |

| Flange Width | 1.35 inches (3.4 cm) to 3.15 inches (8 cm) | Supports machines and light vehicle frames |

| Thickness | 0.12 inches (3 mm) to 0.4 inches (10 mm) | For heavy-duty work and earthquake-safe frames |

This mix of shape and size makes cee channel steel useful in many fields.

Key Features

Structural Strength

Cee channel steel is very strong. It can hold heavy weights without bending or breaking. This makes it great for tough building projects.

Lightweight Design

Even though it is strong, cee channel steel is light. This makes it easy to move and install, saving time and energy.

Corrosion Resistance

Some cee channel steel types resist rust, especially with coatings. This helps them last longer, even in tough conditions.

Common Materials

Carbon Steel

Carbon steel is often used for cee channel steel. It is strong and affordable for most jobs.

Stainless Steel

Stainless steel resists rust very well. It is good for places with water or chemicals.

Galvanized Steel

Galvanized steel has a zinc layer for protection. It is strong and works well outdoors.

Types and Specifications of Cee Channel Steel

Types Based on Material

Mild Steel

Mild steel is a popular choice for cee channel steel. It is made from carbon steel and resists rust moderately. It is heavier than other types but costs less. This makes it great for general construction and industrial projects.

Stainless Steel

Stainless steel cee channels resist rust very well. They are ideal for places with water or chemicals, like factories or coastal areas. Though heavier than mild steel, they last longer and are very reliable.

Galvanized Steel

Galvanized steel cee channels have a zinc coating to stop rust. They are perfect for outdoor use, especially near the sea. They are moderately heavy but resist rust well, making them a top choice for outdoor structures.

| Type | Material | Corrosion Resistance | Weight | Typical Applications |

|---|---|---|---|---|

| Mild Steel C-Channel | Carbon Steel | Moderate | Heavy | General construction and industrial use |

| Galvanized Steel C-Channel | Zinc-Coated Steel | High | Moderate | Outdoor structures and marine settings |

| Stainless Steel C-Channel | Stainless Steel | Very High | Heavy | Chemical and moisture-exposed areas |

Coating Options

Galvanized Coating

Galvanized coating adds a zinc layer to cee channel steel. This layer stops rust and makes the steel last longer. It is often used outdoors, like for fences or roof supports.

Powder Coating

Powder coating gives a strong and colorful finish. It protects the steel from scratches and rust. This coating is great for projects where looks matter, like furniture or shelves.

Dimensional Specifications

Standard Sizes

Standard sizes for cee channel steel include widths from 1.35 inches to 3.15 inches. Depths range from 3 inches to 12 inches, and thicknesses are between 0.12 inches and 0.4 inches. These sizes work for most construction needs.

Customizable Dimensions

If standard sizes don’t fit your needs, you can customize them. Manufacturers can change the width, depth, and thickness to match your project. This ensures cee channel steel fits perfectly for special designs.

| Dimension Type | Measurement Range |

|---|---|

| Width | 1.35" - 3.15" (3.4 - 8 cm) |

| Depth | 3" - 12" (7.6 - 30.5 cm) |

| Thickness | .12" - .4" (3 - 10 mm) |

| Length | 4' - 20' (1.22 - 6.1 m) |

Industry Standards

When using cee channel steel, it must follow certain rules. These rules ensure the material is safe, strong, and fits your needs. Two important standards are ASTM and ISO.

ASTM Standards

ASTM stands for the American Society for Testing and Materials. They create rules for materials like cee channel steel. These rules check strength, makeup, and how well it works. For example:

- ASTM A36: This rule is for carbon steel in cee channels. It makes sure the steel is strong and lasts for building projects.

- ASTM A123: This rule is about galvanized coatings. It ensures the zinc layer stops rust on cee channel steel.

Following ASTM rules means your steel will work well under stress. These rules also help prevent problems in important projects.

Tip: Always look for the ASTM label on steel. It shows the material meets the needed rules.

ISO Standards

ISO stands for the International Organization for Standardization. They set worldwide rules for materials and processes. ISO rules make sure cee channel steel is reliable everywhere. Important rules include:

- ISO 9001: This rule checks quality management. Companies with this certification make high-quality cee channel steel.

- ISO 12944: This rule is about stopping rust. It ensures coatings on cee channel steel can handle tough conditions.

Using ISO-certified steel gives you confidence. You know the material meets global safety and quality rules.

Note: Check for ISO labels when buying cee channel steel. It proves the product follows international rules for quality.

Knowing ASTM and ISO rules helps you pick the right materials. These rules make sure your projects are safe, strong, and dependable.

How is Cee Channel Steel Made?

Choosing Materials

Making cee channel steel starts with picking the right steel. The steel must be strong, long-lasting, and resist rust. Carbon steel is cheap and strong, so it’s often used. Stainless steel is great for wet or chemical-filled places because it doesn’t rust. Alloy steel is another choice, as it handles wear and tear well.

Before making the steel, workers check the materials carefully. They test the steel’s makeup and strength to meet rules. This step ensures the final product works well in different jobs.

Shaping the Steel

After choosing materials, the steel is shaped into a C. Machines use heat or cold to roll the steel into shape. Cooling systems, like air or water, stop the steel from bending wrong. This keeps the steel strong and in good shape.

If the steel twists or bends during rolling, machines fix it. These machines make sure the steel is the right size and shape. This step is important so the steel fits perfectly in buildings or factories.

Cutting and Designing

Next, the steel is cut and shaped to match designs. Special tools, like saws or cutters, make sure the sizes are exact. These tools save material and keep the cuts accurate.

Manufacturers can change the steel’s size to fit your needs. Whether you need common sizes or special ones, the cutting process makes it work. Quality checks ensure the steel is strong and the right size for your project.

Coating and Finishing

Coating and finishing make cee channel steel stronger and better-looking. These steps protect the steel from damage and help it last longer. You can pick the right option based on your project.

A popular method is galvanization, which adds a zinc layer to the steel. This layer stops rust and makes the steel great for outdoor or marine use. Another choice is powder coating, which gives a smooth, colorful finish. It not only looks nice but also protects against scratches and rust.

| Surface Treatment | Description |

|---|---|

| Galvanization | Zinc coating to stop rust, perfect for outdoor and marine use. |

| Powder Coating or Painting | Adds color and extra protection from environmental damage. |

The finishing process also includes cleaning and polishing the steel. This step removes flaws and makes the surface smooth. A good finish improves how the steel works and looks, making it great for furniture or decorations.

Quality Control and Testing

Quality control checks ensure cee channel steel is safe and reliable. Factories use special tools to test its size, strength, and durability. These tests prove the steel can handle heavy loads and resist damage.

Size checks confirm the web height, flange width, and thickness are correct. Strength tests measure how much weight the steel can hold. Factories use advanced machines for accurate results, like measuring and strength-testing tools.

| Quality Control Measure | Purpose |

|---|---|

| Dimensional Checks | Make sure web height, flange width, and thickness are correct. |

| Mechanical Tests | Check strength and how much weight the steel can hold. |

| Advanced Equipment | Use special machines for precise testing. |

| Industry Standards | Follow ASTM and ISO rules to meet global quality standards. |

By following ASTM and ISO rules, factories ensure high-quality steel. These checks give you confidence that the steel will work well in tough jobs.

Applications of Cee Channel Steel

Construction Industry

Framing and Support Structures

Cee channel steel is very important in construction. It is strong but not heavy, making it great for building frames. You can see it in buildings, bridges, and other big projects. Its light weight makes it easy to move and install. This saves both time and effort.

| Application Area | Description |

|---|---|

| Structural Framing | Gives strong support without adding extra weight. |

| Wall Studs | Builds sturdy walls for construction projects. |

| Roof Trusses | Covers long spaces in roofs, especially in factories. |

| Bridge Decks and Trusses | Handles heavy traffic loads in bridges effectively. |

Roofing and Wall Systems

Cee channel steel works well for roofs and walls. It doesn’t rust easily, so it lasts long outside. Use it for strong roof supports or wall frames. This is especially helpful in places with bad weather.

Automotive Industry

Vehicle Frames

Cee channel steel is key in making car frames. It is strong but light, helping cars use less fuel. It also keeps vehicles safe by holding heavy loads.

- Used in car frames for strength and lightness.

- Helps save fuel by lowering vehicle weight.

- Resists rust, good for tough weather conditions.

Reinforcement Components

Cee channel steel adds extra support to vehicles. It strengthens important parts, keeping vehicles steady under pressure. This is crucial for trucks and buses.

Industrial Applications

Machinery and Equipment

Cee channel steel supports heavy machines in factories. It is strong but not too heavy, helping machines work better. This balance is important for saving costs and improving efficiency.

| Property/Application | Description |

|---|---|

| Strength-to-weight ratio | Gives strong support without being too heavy. |

| Structural reliability | Keeps machines stable and safe during use. |

| Rigidity and durability | Handles heavy loads and stays aligned for precise work. |

| Backbone of conveyor systems | Keeps conveyor systems straight for smooth operations. |

Storage Racks and Shelving

Cee channel steel is great for storage racks. It is strong and lasts long, making it perfect for warehouses. These racks can hold heavy items without breaking.

Other Uses

DIY Projects

Cee channel steel is great for DIY projects at home. Its light weight makes it simple to carry and use alone. You can build strong furniture like tables, chairs, or shelves. These items will last a long time because of its strength.

For gardening, cee channel steel is very useful. It can make raised garden beds or trellises that won’t rust. These structures stay in good shape outside. You can also use it for home fixes, like strengthening door frames or making storage spaces.

Tip: Measure your area carefully before cutting cee channel steel. This helps your project fit perfectly.

Many people like cee channel steel because it’s easy to customize. You can cut, drill, or weld it to match your ideas. Its flexibility lets you create unique and fun designs.

Custom Fabrications

Cee channel steel works well for custom-made items. It’s flexible and fits special designs or needs. You can make custom brackets, frames, or supports with it.

For businesses, cee channel steel is great for specific industrial tasks. It can be used to build custom conveyor systems or special shelving units. Its strength and durability make it perfect for these jobs.

| Custom Fabrication Uses | Benefits |

|---|---|

| Brackets and Supports | Strong and dependable |

| Conveyor Systems | Long-lasting and sturdy |

| Unique Shelving Units | Can be adjusted to any space |

Note: Always use the right tools and safety gear when working. This keeps your work safe and accurate.

Whether for hobbies or work, cee channel steel has many uses. Its strength, flexibility, and easy customization make it a favorite for creative projects.

Benefits of Using Cee Channel Steel

Durability and Longevity

Cee channel steel is known for being very strong. Its special shape and materials let it hold heavy loads. It doesn’t bend or break easily, making it dependable. This is why it’s used in construction, cars, and factories. It handles wear and tear really well.

It also lasts longer because it resists rust. Coatings like galvanization or powder finishes protect it. These coatings stop rust, even in tough weather. For outdoor or wet areas, this keeps your steel in good shape for years.

Tip: Use coated cee channel steel in wet or coastal areas. This helps it last longer.

Cost-Effectiveness

Cee channel steel is strong and affordable, saving you money. Its light weight makes it cheaper to move and install. This lowers labor and shipping costs. Plus, it can be recycled, which is better for the environment. It’s a smart choice compared to concrete or aluminum.

- Mild steel channels are important in the global steel market.

- Urban growth and government projects increase demand for C-channel steel.

- Big plans, like the U.S. $1.2 trillion infrastructure plan, show its importance.

As cities grow, cee channel steel becomes even more cost-effective. Its low price and high demand make it popular for building and industrial jobs.

Versatility in Applications

Cee channel steel works for many different jobs. It’s strong but light, so it’s great for building frames, roofs, and walls. In cars, it strengthens frames and other parts.

In factories, it supports machines, conveyor belts, and storage racks. You can also customize it for special projects. Even for DIY projects, it’s useful for furniture or garden tools.

Note: Cee channel steel is flexible. It’s perfect for big projects or small home tasks.

Ease of Installation

Cee channel steel is simple to install. Its lightweight design makes it easy to carry and move. Unlike heavier materials, it requires less effort during construction. This also means you don’t need big machines, saving time and money.

Its uniform shape fits well in most projects. You can align and secure it easily with basic tools. This reduces mistakes and speeds up assembly. Whether building a frame, roof, or rack, installation is quick and straightforward.

Another benefit is its flexibility. You can cut, drill, or weld it to fit your needs. This makes it great for custom designs or tight spaces. Even for DIY projects, its size and shape make it easy to handle.

Tip: Always wear safety gear when cutting or welding cee channel steel. This keeps you safe and ensures accurate work.

Sustainability and Recyclability

Cee channel steel is eco-friendly and recyclable. You can recycle it completely, reducing waste and saving resources. Many cee channel steel products are made from recycled materials, lowering their environmental impact.

Recycling steel uses less energy than making new steel. Scrap steel is melted to create new products, cutting energy use and pollution. This process helps reduce greenhouse gas emissions and supports a cleaner planet.

- Cee channel steel is fully recyclable and often made from recycled materials.

- Recycling saves energy by reusing scrap steel.

- Its durability reduces waste by lasting longer.

Steel’s long life adds to its eco-friendliness. Its strength and rust resistance mean fewer replacements. This saves money and lowers the environmental impact of your projects.

Note: Using cee channel steel helps the environment while providing strong, reliable materials for your projects.

Cee channel steel is shaped like the letter "C." It is strong and useful for many jobs. The vertical part, called the web, holds pressure. The horizontal parts, called flanges, stop bending. This design makes it light but strong. It is used in buildings, cars, and factories. You can also use it for custom projects like shelves or frames.

More people are using cee channel steel because cities are growing. It lasts a long time and costs less than other materials. You can recycle it, which helps the environment. Try using cee channel steel to make your projects stronger and better.

FAQ

What makes Cee channel steel special?

Cee channel steel is shaped like a "C." This shape makes it strong but light. It is useful for building, cars, and factories. It also resists rust, so it lasts longer in tough conditions.

Can Cee channel steel sizes be changed?

Yes, you can change the size of Cee channel steel. Manufacturers can make it wider, deeper, or thicker to fit your needs. This helps it work well for special projects or designs.

Is Cee channel steel good for outdoor use?

Yes, Cee channel steel works outside if coated. Galvanized or powder coatings stop rust and protect it from bad weather. This makes it great for fences, roofs, and other outdoor jobs.

How do you put Cee channel steel in place?

Cee channel steel is easy to install. It is light, so you can move it easily. You can cut, drill, or weld it with simple tools. Use screws or bolts to keep it steady.

Is Cee channel steel good for the environment?

Yes, Cee channel steel is eco-friendly. You can recycle it completely, which saves resources. Many pieces are made from recycled steel. It lasts a long time, so you don’t need to replace it often.