20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

Product Overview

الخصائص المعدنية

يظهر فولاذ S1 بنية ميكروية مارتنسيتية بعد التصلب، مع جزيئات كربيد دقيقة موزعة في جميع أنحاء المصفوفة. يوفر محتوى الكربون المتحكم فيه وسبائك الكروم-التنجستن مقاومة ممتازة للتآكل مع الحفاظ على متانة جيدة. تضمن بنية الحبوب الدقيقة التي تم تحقيقها من خلال عملية التشكيل المتحكم فيها من MetalZenith توزيع صلابة موحد وتقلل من خطر التشقق أثناء المعالجة الحرارية.

عملية المعالجة الحرارية

تستخدم MetalZenith بروتوكولات معالجة حرارية دقيقة تشمل التسخين المسبق إلى 650-700 درجة مئوية، والتسخين الأوستنيتي عند 850-900 درجة مئوية، تليها التبريد بالماء والتخمير عند 150-200 درجة مئوية لتحقيق مستويات صلابة مثلى تتراوح بين 60-64 HRC. تضمن أفراننا ذات الجو المتحكم فيه الحد الأدنى من إزالة الكربون والأكسدة، مما يحافظ على سلامة السطح الضرورية لتطبيقات أدوات القطع.

عملية التصنيع المتقدمة

تبدأ عملية التصنيع لدينا بالذوبان بالتحريض في الفراغ لضمان تجانس كيميائي، تليها عملية تشكيل متحكم فيها مع مراقبة دقيقة لدرجة الحرارة. يخضع المادة لعملية تخفيف الإجهاد والتسخين الشامل بما في ذلك الاختبار بالموجات فوق الصوتية والتحقق من الصلابة لضمان جودة متسقة في كل دفعة.

اختبارات الجودة المتخصصة

تجري MetalZenith اختبارات جودة شاملة خاصة بتطبيقات فولاذ الأدوات، بما في ذلك رسم توزيع صلابة روكويل عبر المقاطع العرضية، وتحليل حيود الأشعة السينية لمحتوى الأوستنيت المتبقي (عادةً <5%)، وفحص معدني لتوزيع الكربيد، واختبار إجهاد الشعاع الدوار لتحديد حدود التحمل تحت ظروف التحميل الدوري.

اعتبارات تقنية خاصة بالتطبيقات

لتطبيقات أدوات القطع، يوفر محتوى الكربون العالي في S1 احتفاظًا ممتازًا بالحواف ومقاومة للتآكل. في تطبيقات القوالب والمطرقات، تمنع المتانة المتوازنة التقطيع تحت الأحمال الصدمية. بالنسبة للأدوات الدقيقة، تضمن الاستقرار الأبعاد بعد المعالجة الحرارية قياسات دقيقة. في مكونات السيارات، يوفر الجمع بين الصلابة ومقاومة التعب أداءً موثوقًا تحت ظروف التحميل الدوري.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| الكربون (C) | 0.60 - 0.75 |

| المنغنيز (Mn) | 0.10 - 0.40 |

| السيليكون (Si) | 0.20 - 0.35 |

| الكروم (Cr) | 1.00 - 1.40 |

| التنجستن (W) | 1.50 - 3.00 |

| الفوسفور (P) | ≤ 0.030 |

| الكبريت (S) | ≤ 0.030 |

⚙️ Mechanical Properties

| الخاصية | القيمة |

|---|---|

| الصلابة (HRC) | 60 - 64 |

| قوة الضغط (MPa) | ≥ 2800 |

| صلابة الصدمة (J) | 15 - 25 |

| مؤشر مقاومة التآكل | 8.5/10 |

| قابلية التصلب (mm) | 25 - 40 |

| قوة التعب (MPa) | ≥ 450 |

🔬 Physical Properties

| الخاصية | القيمة |

|---|---|

| الكثافة (غ/سم³) | 7.80 |

| نقطة الانصهار (°م) | 1480 - 1520 |

| الموصلية الحرارية (W/m·K) | 42.7 |

| التوسع الحراري (×10??/K) | 11.9 |

| معامل المرونة (GPa) | 210 |

| نسبة بواسون | 0.27 - 0.30 |

📏 Product Specifications

| المواصفات | التفاصيل |

|---|---|

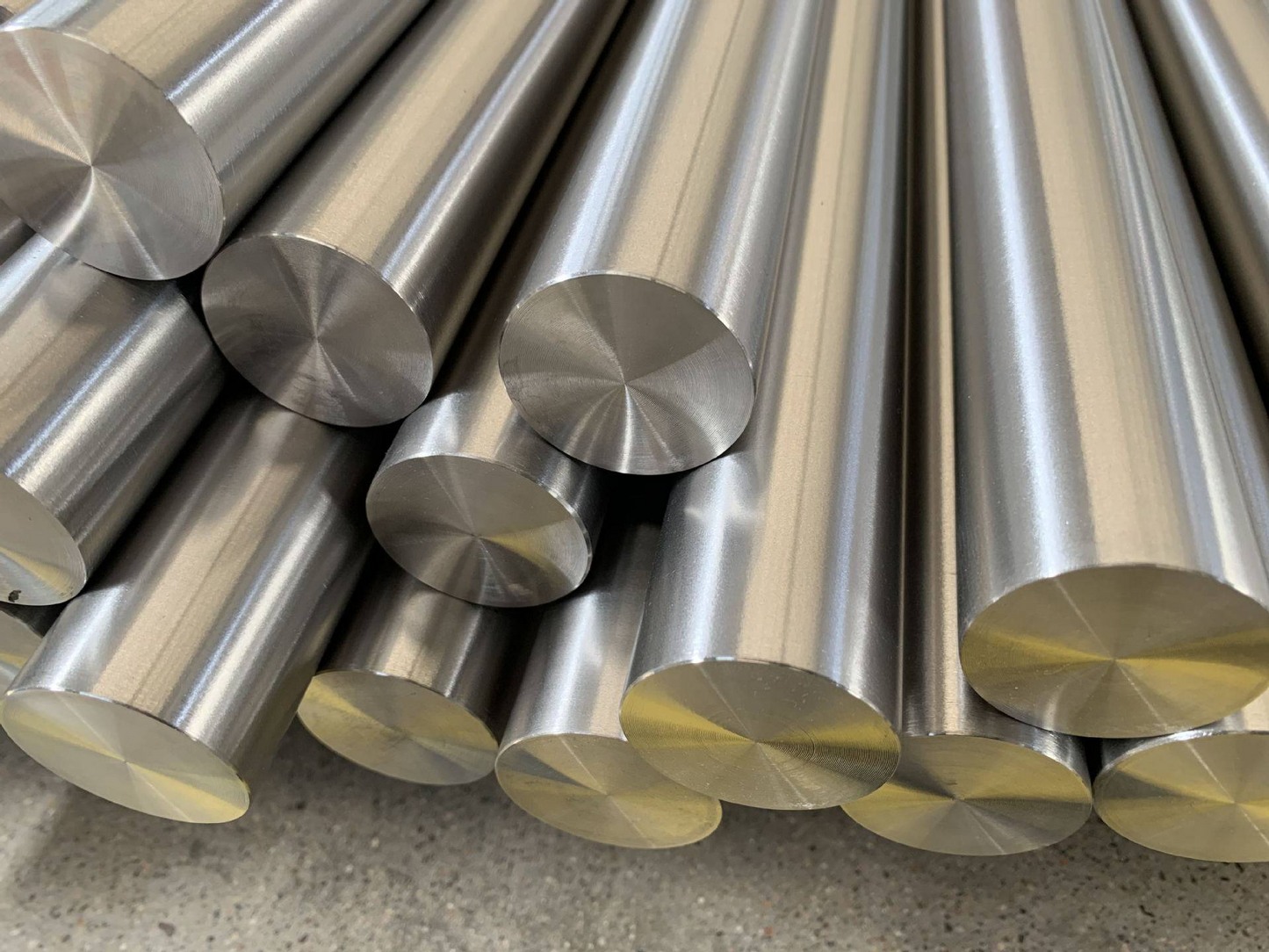

| الأشكال المتاحة | أشرطة دائرية، أشرطة مسطحة، قطع أدوات، مخزون دقيق الأرض |

| نطاق القطر | 3 - 300mm |

| نطاق السماكة | 5 - 150mm |

| نطاق الطول | 100 - 6000mm |

| الامتثال للمعايير | ASTM A681, AISI S1, DIN 1.2550 |

| حالة المعالجة الحرارية | م Annealed, Hardened & Tempered, أو As-Forged |

| تشطيب السطح | مدرفل على الساخن، مسحوب على البارد، دقيق الأرض |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing سبيكة الصلب S1

تقنية صهر الفراغ الدقيق

تستخدم MetalZenith تقنية الصهر بالتحريض الفراغي المتقدمة تليها التشكيل المنضبط لتحقيق تجانس كيميائي متفوق وبنية حبيبية مصقولة. تضمن عملية التصنيع الدقيقة لدينا توزيعًا متسقًا للكربيد وتقضي على الشوائب، مما يؤدي إلى تحسين عمر الأداة وأداء القطع.

اختبار الفولاذ الأدوات الشامل

تشمل بروتوكولات الاختبار المتخصصة لدينا رسم خرائط توزيع صلابة روكويل بالتفصيل، وتحليل محتوى الأوستينيت المتبقي باستخدام حيود الأشعة السينية، وتقييم توزيع الكاربيد من خلال الفحص المعدني، واختبارات شاملة لقوة التعب لضمان أداء الأدوات وموثوقيتها المثلى.

حلول معالجة الحرارة المخصصة

تقدم MetalZenith خدمات معالجة حرارية مخصصة تشمل تقنيات التصلب، والتخمير، وعمليات تخفيف الضغط بدقة. يقدم خبراؤنا في علم المعادن توصيات معالجة حرارية محددة للتطبيقات ودعمًا فنيًا لتحسين أداء الأدوات وفقًا لمتطلبات القطع والتشكيل الخاصة بك.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات