20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

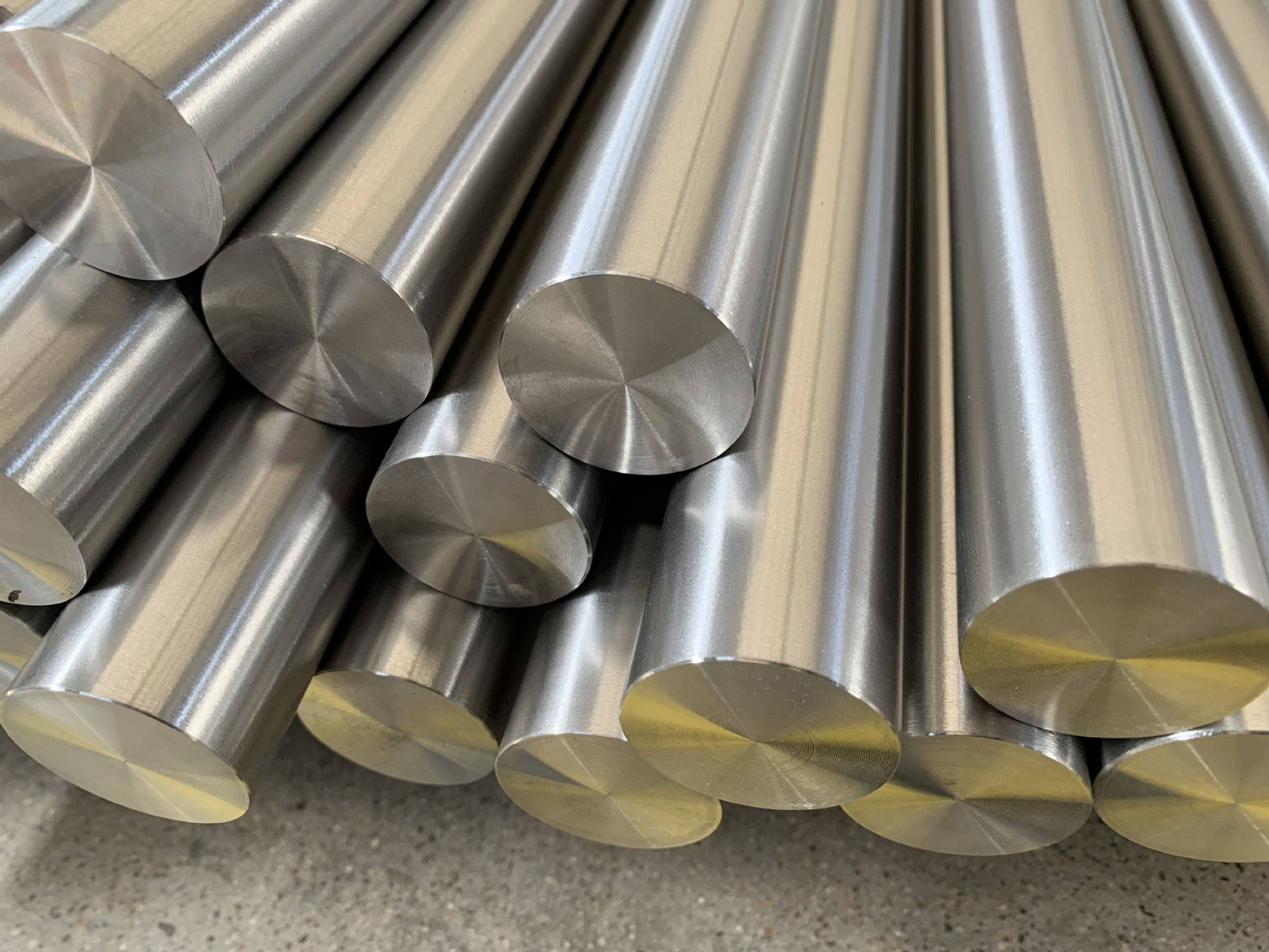

Product Overview

الخصائص المعدنية

EN 1.4307 هو فولاذ مقاوم للصدأ من النوع الأوستنيتي مع هيكل بلوري مكعب مركزي الوجه يوفر قابلية ممتازة للتشكيل والصلابة. إن محتوى الكربون المنخفض (≤ 0.030%) يقلل من ترسيب الكربيد، مما يضمن مقاومة فائقة للتآكل بين الحبيبات وقابلية اللحام. التركيبة المتوازنة من الكروم والنيكل تخلق مصفوفة أوستنيتية مستقرة مع مقاومة استثنائية للتآكل في بيئات متنوعة.

عملية المعالجة الحرارية

تطبق MetalZenith عملية التلدين في المحلول عند 1050-1100°C تليها تبريد سريع لتحقيق التركيب المجهري الأمثل. هذه المعالجة الحرارية تذوب الكربيدات وتضمن هيكل حبيبي أوستنيتي موحد. يمكن أن يزيد العمل البارد من القوة بشكل كبير، مع الحفاظ على قابلية تشكيل ممتازة. قد يتم تطبيق تلدين تخفيف الضغط عند 400-450°C لتحقيق استقرار الأبعاد في التطبيقات الدقيقة.

عملية التصنيع

تبدأ عملية الإنتاج لدينا بصهر فرن القوس الكهربائي تليها إزالة الكربون بالأرجون والأكسجين (AOD) للتحكم الدقيق في التركيبة. يتم تطوير الخصائص الميكانيكية المرغوبة من خلال الدرفلة الساخنة عند 1150-950°C، بينما تحقق الدرفلة الباردة الأبعاد النهائية وجودة السطح. تضمن عمليات التنظيف والتخميل المتقدمة من MetalZenith مقاومة مثالية للتآكل وتشطيب السطح.

معايير الجودة والاختبار

تخضع جميع منتجات EN 1.4307 لاختبارات شاملة تشمل التحليل الكيميائي بواسطة مطيافية الانبعاث الضوئي، والتحقق من الخصائص الميكانيكية من خلال اختبارات الشد والصلابة، وتقييم مقاومة التآكل. تضمن طرق الاختبار غير التدميرية بما في ذلك الفحص بالموجات فوق الصوتية واختبار التيار الدوامي الجودة الداخلية. تحافظ MetalZenith على تتبع كامل من المواد الخام حتى الفحص النهائي، مما يوفر وثائق كاملة والامتثال للشهادات.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| الكربون (C) | ≤ 0.030 |

| السيليكون (Si) | ≤ 1.00 |

| المنغنيز (Mn) | ≤ 2.00 |

| الفوسفور (P) | ≤ 0.045 |

| الكبريت (S) | ≤ 0.030 |

| الكروم (Cr) | 17.50 - 19.50 |

| النيكل (Ni) | 8.00 - 10.50 |

| النيتروجين (N) | ≤ 0.10 |

| الحديد (Fe) | التوازن |

⚙️ Mechanical Properties

| الخاصية | القيمة |

|---|---|

| قوة الشد (Rm) | 520 - 670 ميغاباسكال |

| قوة الخضوع (Rp0.2) | ≥ 205 ميغاباسكال |

| التمدد (A5) | ≥ 45% |

| الصلابة (HRB) | ≤ 92 |

| الصلابة (HV) | ≤ 200 |

| طاقة الصدمة (KV) | ≥ 120 جول (عند 20°م) |

| معامل يونغ | 200 جيجاباسكال |

| حد التعب | 245 ميغاباسكال (10&sup7; دورة) |

🔬 Physical Properties

| الخاصية | القيمة |

|---|---|

| الكثافة | 8.00 g/cm³ |

| نقطة الانصهار | 1400 - 1450°C |

| معامل التمدد الحراري (20-100°C) | 16.0×10-6/K |

| معامل التمدد الحراري (20-300°C) | 17.0×10-6/K |

| الموصلية الحرارية (20°C) | 15 W/m·K |

| السعة الحرارية النوعية | 500 J/kg·K |

| المقاومة الكهربائية (20°C) | 0.73 µΩ·m |

| نفاذية مغناطيسية | 1.02 µr (max) |

| نسبة بواسون | 0.27 - 0.30 |

📏 Product Specifications

| المواصفات | الخيارات المتاحة |

|---|---|

| أشكال المنتجات | أوراق، ألواح، قضبان، قضبان، أنابيب، مواسير، لفات، شرائط |

| سمك الورقة | 0.3 - 6.0 مم |

| سمك اللوحة | 6.0 - 100 مم |

| قطر القضيب | 6 - 300 مم |

| قطر الأنبوب الخارجي | 6 - 219 مم |

| تشطيبات السطح | 2B، BA، No.4، HL، مرآة، مخلل |

| الامتثال للمعايير | EN 10088، ASTM A240/A276/A312، JIS G4303/G4304 |

| تحمل الأبعاد | ±0.1 مم (سمك)، ±1.0 مم (عرض/طول) |

| حالة الحافة | حافة مطحنة، حافة مقطوعة، حافة مشذبة |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing 1.4307

تكنولوجيا الصهر بالفراغ المتقدمة

تستخدم MetalZenith عمليات الصهر بالتحريض الفراغي المتطورة (VIM) وإعادة الصهر بالكهرباء (ESR) لإنتاج EN 1.4307 مع نقاء وتجانس استثنائيين. تضمن تقنيات التكرير المتقدمة لدينا التحكم الدقيق في محتوى الكربون أقل من 0.030%، مما يوفر قابلية لحام ومقاومة للتآكل تفوق طرق الإنتاج القياسية.

نظام شامل لمراقبة الجودة

نظام إدارة الجودة المتكامل لدينا يتميز بمراقبة التركيب الكيميائي في الوقت الفعلي، وفحص الأبعاد الآلي، وقدرات الاختبار غير التدميري المتقدمة. يقوم مختبر MetalZenith المعتمد بإجراء التحقق الكامل من الخصائص الميكانيكية، مما يضمن أن كل دفعة من EN 1.4307 تلبي أو تتجاوز المعايير الدولية مع وثائق تتبع المواد الكاملة.

تخصيص مرن وإمداد عالمي

MetalZenith تقدم خيارات تخصيص واسعة لـ EN 1.4307، بما في ذلك تشطيبات سطحية متخصصة، وتحملات دقيقة، وأبعاد مخصصة. تضمن شبكة سلسلة التوريد العالمية لدينا تسليم موثوق في جميع أنحاء العالم، بينما يوفر فريقنا الهندسي الفني تحسين المواد المحددة للتطبيق ودعمًا فنيًا شاملاً طوال دورة حياة المشروع.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات