20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

Product Overview

الخصائص المعدنية

يتميز الفولاذ البحري DH36 بتركيب ميكروهيكلي دقيق الحبيبات من النوع الفيريت-بيرليتي تم تحقيقه من خلال عمليات الدرفلة المنضبطة والتبريد المعجل. توفر إضافة عناصر الميكروسبائك مثل النيوبيوم والفاناديوم والتيتانيوم تحسين الحبيبات وتقوية الترسيب، مما يؤدي إلى تحسين الخصائص الميكانيكية وزيادة المتانة في درجات الحرارة المنخفضة.

عملية المعالجة الحرارية

تستخدم MetalZenith عملية معالجة حرارية موحدة للفولاذ DH36، تتضمن التسخين إلى 920-950°C تليها التبريد في الهواء. تضمن هذه المعالجة تركيبًا ميكروهيكليًا موحدًا، وتخفيف الإجهاد، وخصائص ميكانيكية مثالية. تحافظ مرافق المعالجة الحرارية المتقدمة لدينا على التحكم الدقيق في درجة الحرارة بدقة ±5°C طوال العملية.

عملية التصنيع

تستخدم إنتاج الفولاذ DH36 لدينا صهر فرن القوس الكهربائي تليه تنقية في القادوس وتفريغ فراغي لتحقيق نظافة متفوقة وتجانس كيميائي. يخضع الفولاذ للدرفلة المنضبطة مع نسب تقليل محددة ودرجات حرارة إنهاء لتحسين هيكل الحبيبات والخصائص الميكانيكية.

معايير الجودة والاختبار

تخضع كل دفعة من فولاذ DH36 لاختبارات شاملة بما في ذلك التحليل الكيميائي بواسطة طيفية الانبعاث الضوئي، والتحقق من الخصائص الميكانيكية من خلال اختبارات الشد والصدمات، واختبار الموجات فوق الصوتية للسلامة الداخلية، وفحص الأبعاد. تحافظ MetalZenith على تتبع كامل من المواد الخام إلى المنتجات النهائية، مما يضمن الامتثال لمتطلبات جمعيات التصنيف البحرية والمعايير الدولية.

قابلية اللحام والتصنيع

يظهر فولاذ DH36 قابلية لحام ممتازة مع معظم عمليات اللحام التقليدية بما في ذلك SMAW وGMAW وFCAW وSAW. يتم التحكم في المعادل الكربوني (CEV) ليكون ≤0.40% لضمان قابلية لحام جيدة دون الحاجة إلى التسخين المسبق لمعظم التطبيقات. قد تكون المعالجة الحرارية بعد اللحام مطلوبة للأقسام السميكة أو التطبيقات الحرجة.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| الكربون (C) | ≤ 0.18 |

| المنغنيز (Mn) | 0.90 - 1.60 |

| السيليكون (Si) | 0.10 - 0.50 |

| الفوسفور (P) | ≤ 0.035 |

| الكبريت (S) | ≤ 0.035 |

| الألمنيوم (Al) | ≥ 0.015 |

| النيوبيوم (Nb) | 0.02 - 0.05 |

| الفاناديوم (V) | 0.05 - 0.10 |

| التيتانيوم (Ti) | 0.02 - 0.05 |

| النحاس (Cu) | ≤ 0.35 |

| الكروم (Cr) | ≤ 0.20 |

| النيكل (Ni) | ≤ 0.40 |

| الموليبدينوم (Mo) | ≤ 0.08 |

⚙️ Mechanical Properties

| الخاصية | القيمة |

|---|---|

| قوة العائد (ReH) | ≥ 355 MPa |

| قوة الشد (Rm) | 490 - 630 MPa |

| التمدد (A5) | ≥ 22% |

| طاقة الصدمة (KV عند 0°C) | ≥ 34 J |

| طاقة الصدمة (KV عند -20°C) | ≥ 24 J |

| صلابة برينل (HB) | 150 - 220 |

| معامل يونغ | 210 GPa |

| نسبة بواسون | 0.30 |

| حد التعب (107 دورة) | 245 MPa |

| صلابة الكسر (KIC) | 150 MPa·m1/2 |

🔬 Physical Properties

| الخاصية | القيمة |

|---|---|

| الكثافة | 7.85 g/cm³ |

| نقطة الانصهار | 1510°C |

| الموصلية الحرارية (20°C) | 54 W/m·K |

| معامل التمدد الحراري (20-100°C) | 12×10-6/K |

| السعة الحرارية النوعية | 500 J/kg·K |

| المقاومة الكهربائية (20°C) | 0.16 µΩ·m |

| نفاذية مغناطيسية | مغناطيسي حديدي |

| درجة حرارة كوري | 770°C |

| الانتشار الحراري | 13.7 mm²/s |

| الانبعاثية (السطح المؤكسد) | 0.79 |

📏 Product Specifications

| المواصفات | التفاصيل |

|---|---|

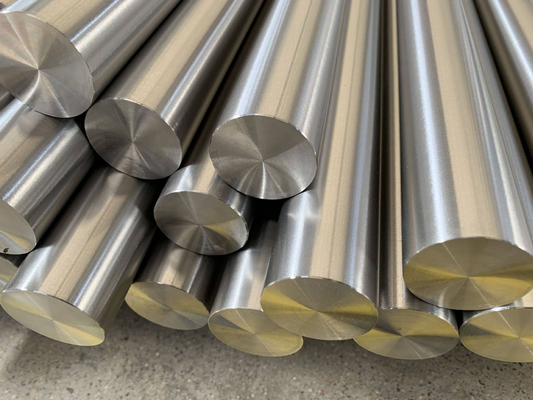

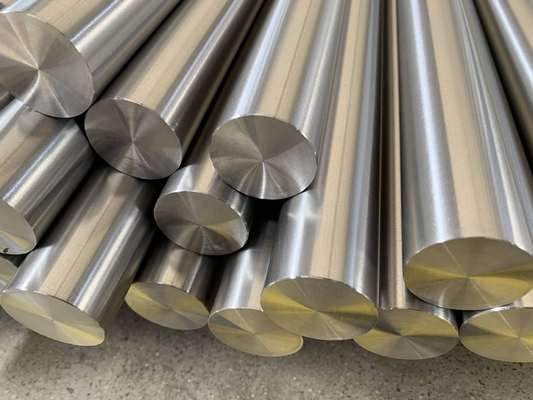

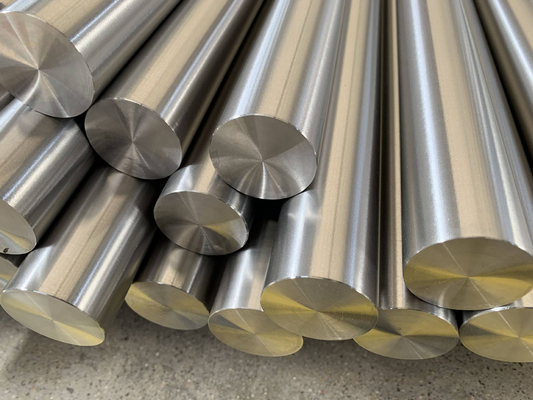

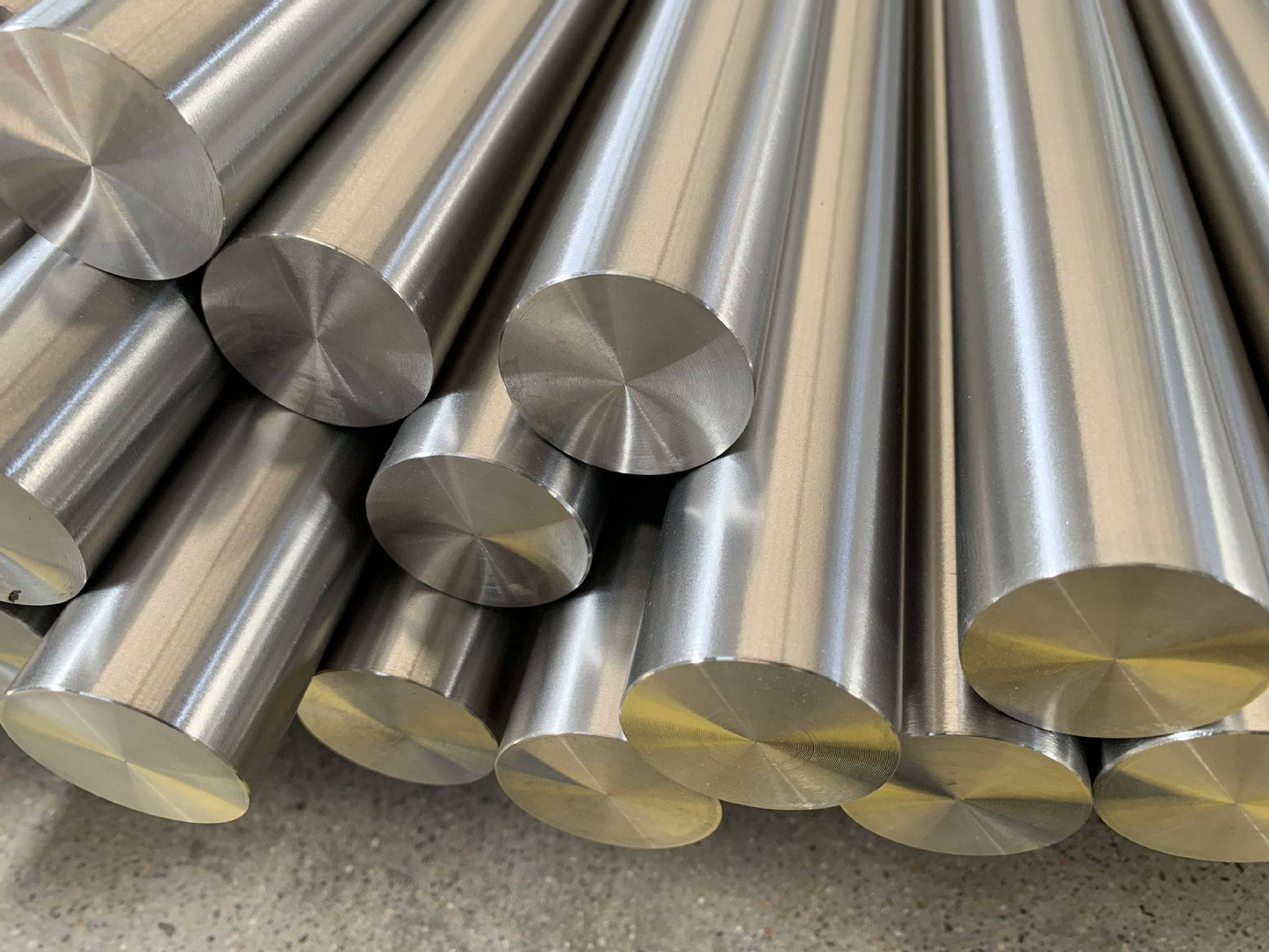

| الأشكال المتاحة | ألواح، صفائح، قضبان، مقاطع، مطروقات |

| نطاق سمك اللوح | 6mm - 150mm |

| نطاق سمك الصفائح | 1.5mm - 6mm |

| نطاق العرض | 1000mm - 4000mm |

| نطاق الطول | 2000mm - 18000mm |

| الامتثال للمعايير | ASTM A131، ABS، DNV-GL، Lloyd's Register، BV |

| تشطيب السطح | مدرفل على الساخن، مُعالج، مُنفجر بالرصاص، مُخلل |

| حالة الحافة | حافة مطحنة، حافة مقصوصة، قطع لهب، مشغول |

| تحمل السمك | ±0.3mm (t≤20mm)، ±0.05t (t>20mm) |

| تحمل العرض | ±5mm |

| تحمل الطول | ±10mm |

| تحمل الاستواء | ≤5mm/m |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing DH36

معالجة حرارية ميكانيكية متقدمة

تستخدم MetalZenith تقنية الدرفلة المتحكم بها والتبريد المعجل لتحقيق هيكل حبيبي مثالي في فولاذ DH36، مما يؤدي إلى خصائص ميكانيكية متفوقة وزيادة في المتانة للتطبيقات البحرية.

نظام شامل لمراقبة الجودة

نظام إدارة الجودة المتكامل لدينا يتضمن مراقبة التركيب الكيميائي في الوقت الحقيقي، واختبارات ميكانيكية آلية، وطرق متقدمة للاختبار غير المدمر لضمان أن كل دفعة من فولاذ DH36 تلبي معايير الصناعة البحرية الصارمة.

تخصيص مرن وإمداد عالمي

تقدم MetalZenith خيارات تخصيص واسعة لصلب DH36 بما في ذلك الأبعاد المحددة، ومعالجات السطح، ومتطلبات الشهادات، مدعومة بشبكتنا العالمية للتوزيع التي تضمن التسليم في الوقت المناسب في جميع أنحاء العالم.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات