20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

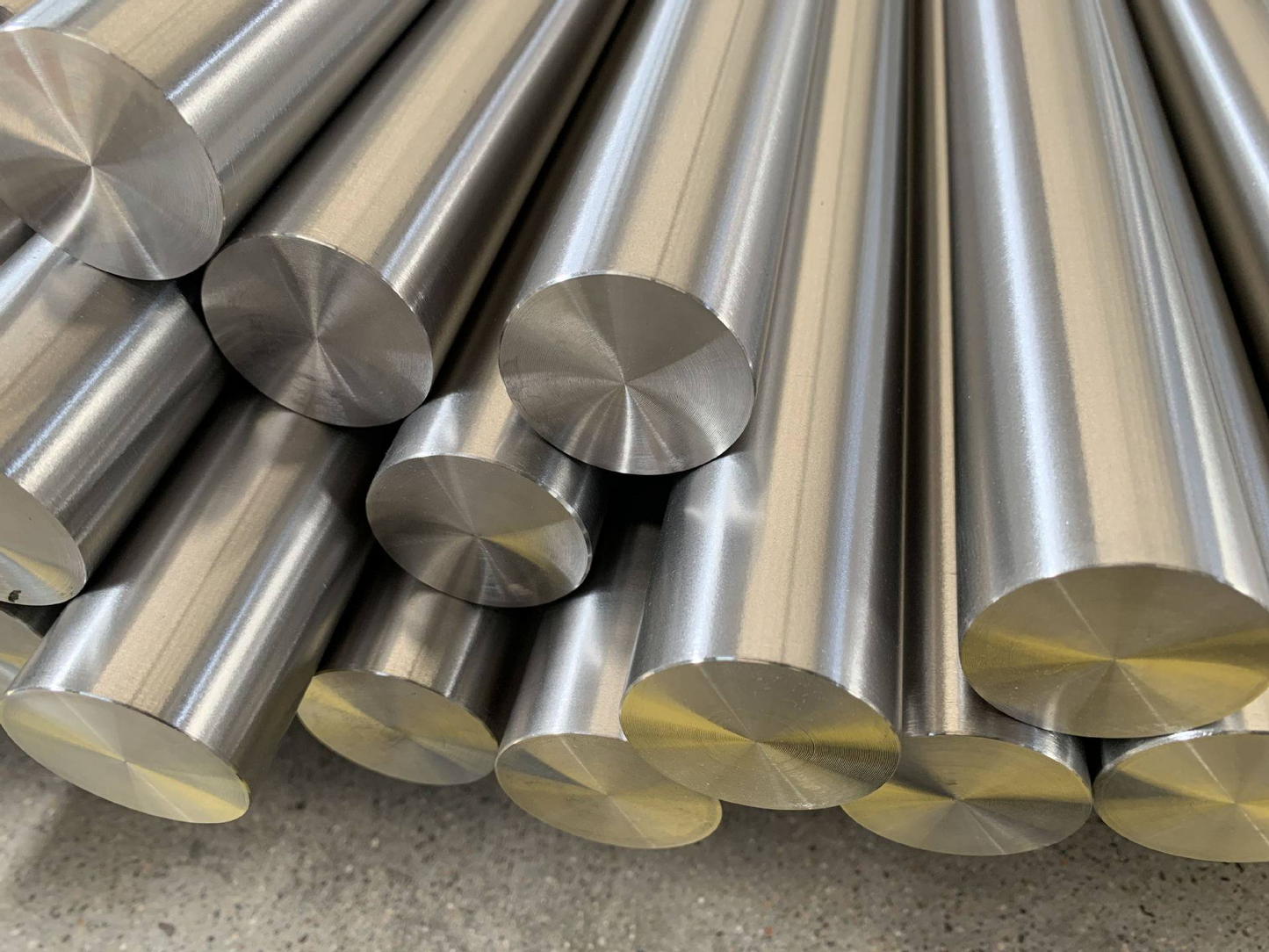

Product Overview

الخصائص المعدنية

AISI D2 هو فولاذ أدوات عمل بارد عالي الكربون وعالي الكروم مع مقاومة ممتازة للتآكل بسبب نسبة الكروم الكربيد العالية. يظهر الفولاذ خصائص تصلب الهواء، مما يسمح بالتصلب الكامل في الأقسام السميكة دون الحاجة إلى وسائط تبريد شديدة. يتكون الميكروهيكل من مصفوفة مارتنزيتية مع كربيدات كروم موزعة بشكل موحد (أنواع M7C3 و M23C6) التي توفر مقاومة استثنائية للتآكل.

عملية المعالجة الحرارية

تشمل عملية المعالجة الحرارية المتحكم بها من MetalZenith التلدين عند 870-900°C، تليها التبريد البطيء لتحقيق أقصى قابلية للتشغيل. يتم التصلب عند 1010-1030°C في جو محمي، تليها التبريد بالهواء أو التبريد بالزيت للأقسام الصغيرة. يتم التخمير عند 150-540°C اعتمادًا على مستوى الصلابة المطلوب، مما يحقق عادةً 58-62 HRC لأداء مثالي.

عملية التصنيع

تبدأ عملية التصنيع لدينا بالذوبان بالتحريض في الفراغ (VIM) لضمان التجانس الكيميائي والنظافة. يخضع الفولاذ لإعادة الذوبان بالتيار الكهربائي (ESR) لمزيد من التنقية وتحسين الجودة. يتم التشكيل الساخن ضمن نطاق درجة حرارة 1150-850°C، تليها عملية تبريد متحكم بها. تتلقى جميع المنتجات اختبارات شاملة بما في ذلك الفحص بالموجات فوق الصوتية، التحليل الكيميائي، والتحقق من الخصائص الميكانيكية.

معايير الجودة والشهادات

تحافظ MetalZenith على رقابة صارمة على الجودة وفقًا لمعايير ISO 9001:2015 و ASTM A681 و EN ISO 4957. تشمل برنامج ضمان الجودة لدينا فحص المواد الواردة، المراقبة أثناء العملية، واختبار المنتج النهائي. تتضمن جميع الشحنات شهادات اختبار المواد مع تحليل كيميائي كامل، خصائص ميكانيكية، والتحقق من الأبعاد. تشمل قدرات الاختبار غير التدميري طرق الفحص بالموجات فوق الصوتية، الجسيمات المغناطيسية، وطرق فحص الصبغة المتغلغلة.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| الكربون (C) | 1.40 - 1.60 |

| الكروم (Cr) | 11.00 - 13.00 |

| الموليبدينوم (Mo) | 0.70 - 1.20 |

| الفاناديوم (V) | 1.10 كحد أقصى |

| المنغنيز (Mn) | 0.60 كحد أقصى |

| السيليكون (Si) | 0.60 كحد أقصى |

| الفوسفور (P) | 0.030 كحد أقصى |

| الكبريت (S) | 0.030 كحد أقصى |

| النيكل (Ni) | 0.30 كحد أقصى |

| النحاس (Cu) | 0.25 كحد أقصى |

⚙️ Mechanical Properties

| الخاصية | القيمة | الحالة |

|---|---|---|

| قوة الشد | 685 MPa | م annealed |

| قوة الخضوع | 450 MPa | م annealed |

| التمدد | 8% | م annealed |

| تقليل المساحة | 15% | م annealed |

| الصلابة (م annealed) | 217 HB كحد أقصى | م annealed |

| الصلابة (م hardened) | 58-62 HRC | م hardened & tempered |

| طاقة الصدمة (Charpy V) | 15-25 J | م hardened & tempered |

| معامل المرونة | 210 GPa | درجة حرارة الغرفة |

| حد التعب | 350 MPa | 107 دورة |

🔬 Physical Properties

| الخاصية | القيمة | درجة الحرارة |

|---|---|---|

| الكثافة | 7.70 g/cm³ | 20°C |

| نقطة الانصهار | 1421°C | - |

| الموصلية الحرارية | 20.0 W/m·K | 20°C |

| الموصلية الحرارية | 25.1 W/m·K | 200°C |

| معامل التمدد الحراري | 10.4×10-6/K | 20-100°C |

| معامل التمدد الحراري | 11.9×10-6/K | 20-400°C |

| السعة الحرارية النوعية | 460 J/kg·K | 20°C |

| المقاومة الكهربائية | 0.55 µΩ·m | 20°C |

| نفاذية مغناطيسية | مغناطيسي حديدي | درجة حرارة الغرفة |

📏 Product Specifications

| المواصفات | الخيارات المتاحة |

|---|---|

| أشكال المنتج | أشرطة دائرية، أشرطة مسطحة، لوحات، صفائح، كتل، قطع مطروقة |

| قطر الشريط الدائري | 6mm - 500mm |

| أبعاد الشريط المسطح | السماكة: 3-100mm، العرض: 10-300mm |

| سماكة اللوحة | 6mm - 200mm |

| سماكة الورقة | 0.5mm - 6mm |

| الطول | حتى 6000mm (أطوال مخصصة متاحة) |

| المعايير | ASTM A681، EN ISO 4957، JIS SKD11، GB Cr12Mo1V1 |

| تشطيب السطح | مدرفل على الساخن، مسحوب على البارد، مصقول، مصقول |

| تحمل الأبعاد | h9 إلى h11 (مسحوب على البارد)، ±0.5mm (مدرفل على الساخن) |

| الحالة | مخمرة، طبيعية، صلبة ومقواة |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing AISI D2

تكنولوجيا الصهر بالفراغ المتقدمة

MetalZenith تستخدم عمليات الصهر بالتحريض الفراغي (VIM) وإعادة الصهر بالتيار الكهربائي (ESR) لتحقيق نظافة استثنائية للصلب مع الحد الأدنى من الشوائب. يضمن صهرنا في جو محكم توزيعًا موحدًا للكربيد وتجانسًا ممتازًا للمادة في جميع أنحاء المقطع العرضي.

تحكم دقيق في معالجة الحرارة

تتميز مرافق المعالجة الحرارية التي تتحكم فيها الكمبيوتر بمراقبة دقيقة لدرجة الحرارة وأنظمة التحكم في الأجواء. وهذا يضمن تجانس صلابة مثالي، واستقرار أبعاد، وخصائص ميكانيكية متسقة مع تباينات في الصلابة ضمن ±1 HRC عبر قطعة العمل بالكامل.

خدمات التخصيص الشاملة

MetalZenith تقدم تخصيصًا كاملاً بما في ذلك التشغيل الدقيق، والمعالجة الحرارية وفقًا لمواصفات العملاء، وخدمات التشطيب السطحي. تضمن شبكة سلسلة التوريد العالمية لدينا تسليمًا موثوقًا مع شهادة كاملة للمواد ودعمًا فنيًا لمتطلبات التطبيقات المحددة.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات