Top Tips for Choosing the Best Copper Sheet for Your Project

Share

Table Of Content

Table Of Content

Choosing the right copper sheet is very important for success. Copper is the third most-used metal in the world. Around 20 million tons of copper are made every year. It is used in construction, electronics, and art because it is so useful. Picking the right copper sheet makes your project last longer. It helps your project handle damage and stay strong. Copper works well because it conducts electricity and bends easily. It also looks great with its special finishes. By learning about copper, you can make your project strong, useful, and beautiful.

Key Takeaways

- Pick the right copper sheet to make your project strong and nice-looking.

- Learn about copper types and their features to choose the best one.

- Choose the right thickness to make it last and easy to use.

- Find a reliable seller with good reviews and experience for quality copper.

- Think about custom options to get sheets that fit your project perfectly.

Material Properties of Copper Sheets

Knowing the material properties of copper sheets is important. These properties show how strong, long-lasting, and good-looking the sheet will be.

Copper Alloys

Copper alloys mix copper with other materials to improve it. For example:

- Brass is made from copper and zinc. It is strong and easy to shape. It is often used for decoration.

- Bronze is a mix of copper and tin. It is very strong and resists rust, making it great for building.

- Other alloys, like those with aluminum or silicon, make copper more heat-resistant and easier to work with.

These alloys keep copper's ability to conduct electricity. They also add features for special uses. Whether you need strength, beauty, or durability, the right alloy will fit your project.

Temper Designations

Tempering changes how copper sheets behave. This process heats and cools the metal to give it certain traits. A soft temper makes the sheet bendable. A hard temper makes it stronger and tougher.

The temper affects things like how much the sheet stretches or how strong it is. For example, soft temper (O60) bends easily. Hard temper (H04) is stronger for tough jobs. Picking the right temper helps your copper sheet work well.

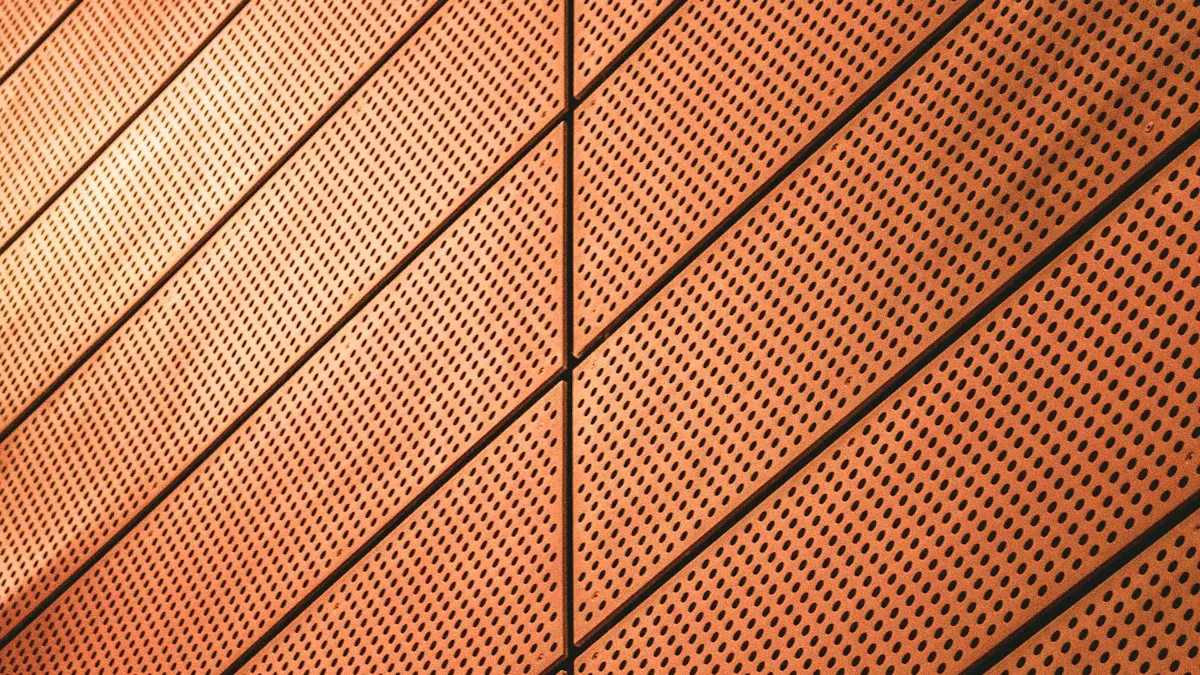

Surface Finishes

The surface finish changes how long the copper lasts and how it looks. A smooth finish lasts longer and looks better. A rough finish wears out faster and may not look as nice.

| Surface Finish Type | Durability Impact | Appearance Impact |

|---|---|---|

| Rougher Surface Finish | Wears out faster | May not look as good |

| Smoother Surface Finish | Lasts longer | Looks better and works well |

Choosing the right finish makes your copper sheet last longer and look great in your project.

Practical Considerations for Copper Sheets

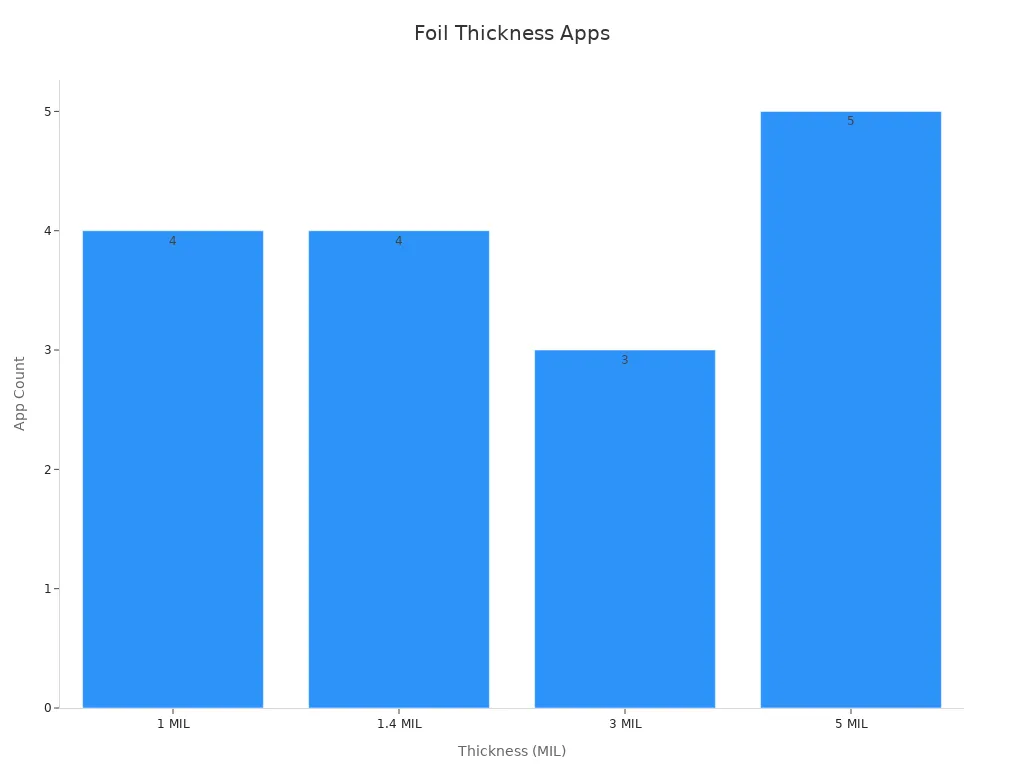

Thickness and Gauge

The thickness of copper sheets is very important. Thin sheets, like 1 MIL or 1.4 MIL, are light. They are easy to cut and great for crafts or small projects. Thicker sheets, like 5 MIL (36 gauge), are stronger. They work well for construction, embossing, and heavy tasks.

| Thickness (MIL) | Description | Applications |

|---|---|---|

| 1 MIL | Very thin, cuts easily. | Scrapbooking, electrical, manufacturing, R&D |

| 1.4 MIL | Slightly thicker, still tears easily. | Paper crafts, electrical, manufacturing, R&D |

| 3 MIL | Thin, wrinkles easily. | Arts and crafts, electrical, R&D |

| 5 MIL (36 gauge) | Strong, cannot tear by hand. | Embossing, home improvement, construction |

Choosing the right thickness makes your project strong and useful.

Size and Quantity

The size and number of sheets depend on your project. Small projects, like jewelry or art, need small sheets. Big projects, like roofing, need large sheets or many pieces. Measure your space to avoid running out of material.

In 2020, the U.S. made 1.2 million tons of copper. This was worth $7.5 billion. Copper is widely used in construction and electronics. Knowing your project size saves time and materials.

Customization Options

Customization helps you get the perfect copper sheet. Many suppliers offer pre-cut sizes, special shapes, and finishes. This is helpful for construction or design projects.

- Construction uses copper for eco-friendly and energy-saving materials.

- Copper is recyclable and lasts a long time, making it popular.

- Electronics and electrical industries also need custom copper sheets.

By customizing, you can make sure the copper fits your project perfectly.

Picking a Trustworthy Copper Sheet Supplier

Choosing the right supplier is crucial for your project’s success. A good supplier provides quality materials, expert advice, and helpful support. Here are important things to think about when picking a supplier.

Certification and Reputation

A supplier’s certification shows their focus on quality. Look for certifications like ISO 9001, which proves they follow industry rules.

| Certification | What It Means | Why It Matters |

|---|---|---|

| ISO 9001 | Shows quality and standard compliance | Ensures reliable and consistent products |

Reputation is also important. Read reviews and customer feedback. A supplier with good reviews is more likely to deliver great products. Picking a certified and trusted supplier ensures your copper sheet meets your needs.

Knowledge and Experience

Experienced suppliers know a lot about copper sheets. They understand alloys, temper types, and thickness options.

| Key Benefits | Explanation |

|---|---|

| Better Choices | Experienced suppliers help you pick the right copper sheet. |

| Meeting Needs | They can match materials to your project’s requirements. |

| Cost Savings | Their knowledge ensures good quality at the right price. |

An experienced supplier can guide you to the best choice for your project.

Extra Services and Help

Some suppliers offer extra services to make your job easier. These include:

- Polishing to give the copper a smooth look.

- Cutting and shaping to fit your project’s size.

- Expert advice to explain material features.

Suppliers with many options and eco-friendly solutions save time and effort. They may also offer recyclable copper sheets for sustainable projects.

By focusing on certifications, experience, and extra services, you can find a supplier who supports your project every step of the way.

Picking the right copper sheet means knowing its features and uses. Each detail helps make your project work well. Learn about alloys, thickness, and custom options to save effort and materials.

Keep in mind, a good supplier gives quality copper and advice.

Start now! Check out copper sheet choices or contact a trusted supplier to complete your project!

FAQ

What is the best copper sheet thickness for crafts?

Thin sheets like 1 MIL or 1.4 MIL are great for crafts. They are light and simple to cut or shape. These work well for scrapbooking, paper crafts, or small decorations.

Can copper sheets be used outdoors?

Yes, copper sheets are good for outdoor use. They resist rust and form a patina over time. This makes them great for roofs, gutters, and outdoor decorations.

How do I clean copper sheets?

Mix lemon juice and salt to clean copper sheets. Gently rub the mix on the surface, then rinse with water. Use a soft cloth for polished finishes to avoid scratching.

Are copper sheets eco-friendly?

Copper sheets are very eco-friendly. Copper can be recycled fully without losing quality. Many suppliers sell recycled copper sheets, making them a green choice for projects.

Can I customize copper sheets for my project?

Yes, suppliers often offer customization options. You can ask for specific sizes, shapes, or finishes. This helps the copper sheet fit your project perfectly, whether for art, construction, or electronics.

Tip: Always ask your supplier about their customization services.