What is 18 Gauge Steel Sheet and Its Key Specifications

Share

Table Of Content

Table Of Content

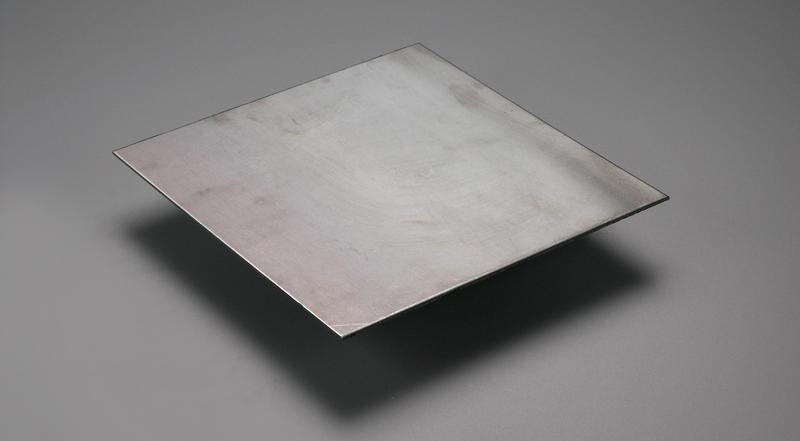

An 18 gauge steel sheet is a thin, flat piece of steel with a thickness that varies slightly depending on the material. For instance:

- Carbon steel measures 0.0478 inches (1.214 mm) thick.

- Stainless steel is slightly thicker at 0.0500 inches (1.270 mm).

- Galvanized steel comes in at 0.0516 inches (1.311 mm).

- Aluminum, being lighter, measures 0.0403 inches (1.024 mm).

These variations occur because each material has distinct properties. Understanding these differences ensures you select the right steel sheet for your specific needs.

Key Takeaways

- Learn about thickness differences in 18 gauge steel sheets. Carbon steel, stainless steel, galvanized steel, and aluminum have different thicknesses for different uses.

- Use a formula to find the weight of 18 gauge steel. Knowing the weight helps with building and making things.

- Pick the best material for your project. Stainless steel is strong, but aluminum is light, so they work for different jobs.

- Keep steel sheets clean to stop rust. Wash them often and use coatings to make them last longer.

- Cut and bend steel the right way. Use good tools and keep the right heat to avoid damage.

Thickness and Material Differences in 18 Gauge Steel Sheets

Standard Thickness

Thickness in Inches and Millimeters

The thickness of an 18 gauge steel sheet changes with the material. For example:

- Carbon steel is 0.0478 inches (1.214 mm) thick.

- Stainless steel is a bit thicker at 0.0500 inches (1.270 mm).

- Galvanized steel measures 0.0516 inches (1.311 mm).

- Aluminum is thinner at 0.0403 inches (1.024 mm).

These differences happen because each material has special traits like strength and density.

Here’s a table showing the thickness for each material:

| Material Type | Thickness (inches) | Thickness (mm) |

|---|---|---|

| Carbon Steel | 0.0478 | 1.214 |

| Stainless Steel | 0.0500 | 1.270 |

| Galvanized Steel | 0.0516 | 1.311 |

| Aluminum | 0.0403 | 1.024 |

| Copper | 0.0490 | 1.245 |

| Brass | 0.0403 | 1.024 |

Tolerance Range

Factories follow rules to keep thickness consistent. But small changes, called tolerances, can happen. These depend on the material and how it’s made. The Manufacturers’ Standard Gage for Sheet Steel ensures 18 gauge steel sheets meet quality standards.

Material-Specific Differences

Stainless Steel vs. Carbon Steel

Stainless steel and carbon steel are different in thickness, weight, and strength. Stainless steel is thicker at 0.0500 inches, while carbon steel is 0.0478 inches. Stainless steel weighs more at 2.31 pounds per square foot, compared to carbon steel’s 2.0 pounds. It is also stronger, making it better for tough jobs.

Aluminum vs. Steel Gauge Measurements

Aluminum sheets are thinner than steel sheets of the same gauge. An 18 gauge aluminum sheet is 0.0403 inches thick. Steel sheets range from 0.0478 to 0.0516 inches. This is because aluminum is lighter and less dense than steel, making it easier to handle.

Key Specifications of 18 Gauge Steel Sheet

Weight Per Square Foot

How to Calculate Weight

To find the weight of an 18 gauge steel sheet, use this formula:

Weight (lbs/ft²) = Thickness (inches) × Density (lbs/in³) × 144

This formula uses thickness and density to estimate weight. For example, stainless steel has a density of 0.289 lbs/in³. This makes its weight about 2.31 lbs per square foot.

Weight Differences by Material

Different materials have unique densities, which change their weight. Here’s a comparison:

| Material | Weight per Square Foot (lbs/ft²) | Weight per Square Meter (kg/m²) |

|---|---|---|

| Cold Rolled Steel | 2.28 | 11.13 |

| Stainless Steel | 2.31 | 11.28 |

| Aluminum Alloys | 0.80 | 3.91 |

Aluminum is much lighter than steel. This makes it great for projects needing less weight. Stainless steel is heavier but stronger, making it more durable.

Dimensional Accuracy and Tolerance

Industry Rules

Factories follow strict rules to make sure 18 gauge steel sheets are accurate. For carbon steel, the thickness is 0.0478 inches with a tolerance of ±0.002 inches. Stainless steel and aluminum allow slightly bigger tolerances, as shown below:

| Material Type | Standard Thickness | Tolerance Range |

|---|---|---|

| Carbon Steel | 0.0478 inches | ±0.002 inches |

| Stainless Steel | 0.0478 inches | ±0.003 inches |

| Aluminum | 0.0478 inches | ±0.0035 inches |

These tolerances make sure the sheets are good for jobs like building or car-making.

What Affects Accuracy

Accuracy depends on how the sheets are made and the tools used. Advanced machines can control thickness very precisely, within ±0.002 inches. Things like material type, heat during making, and cutting methods also matter. Regular checks and following ASTM or ISO rules help keep quality consistent.

Applications of 18 Gauge Steel Sheet

Construction Industry

Roofing and Wall Panels

18 gauge steel is strong and long-lasting. It is often used for roofs and walls. Its thickness helps it resist bad weather. This makes it great for outdoor use. Builders like it because it holds heavy loads well. It can also be shaped into different designs. This adds both style and usefulness to buildings.

Structural Components

18 gauge steel is important for building strong structures. It is used in beams and supports. Its strength keeps buildings stable and safe. It does not bend easily under pressure. This makes it a good choice for homes and offices. It helps create solid and lasting frameworks.

Automotive Industry

Body Panels and Frames

Car makers use 18 gauge steel for body parts. It is strong but easy to shape. This helps make doors, hoods, and other car parts. It is tough with a strength of 31 KSI. Its hardness of 55 Rockwell B adds to its durability. This steel keeps cars strong and efficient.

Exhaust Systems

18 gauge steel is also used in car exhausts. It resists heat and rust very well. Its thickness handles hot gases without damage. This makes exhaust systems last longer. It also reduces the need for repairs over time.

HVAC and Industrial Uses

Ductwork and Ventilation Systems

HVAC systems need 18 gauge steel for ducts. It is strong and flexible for easy installation. It helps air move smoothly through systems. This steel works well in homes and factories. It can handle different weather conditions too.

Machinery and Equipment Components

Machines use 18 gauge steel for many parts. It is great for protective covers and frames. For example, it is used in electrical boxes and equipment cases. This steel lasts a long time, even in tough conditions. It keeps machines working well for years.

Maintenance and Protection of 18 Gauge Steel Sheet

Corrosion Prevention

Coating and Galvanization

To stop rust, treat your 18 gauge steel sheet properly. Coating and galvanizing are great methods. Hot-dipped galvanizing adds a zinc layer. This layer forms zinc oxide, which blocks rust. Coated steel, like G90 or G60, gives different protection levels. G90 has 0.90 ounces of zinc per square foot. It works well for outdoor use and lasts long.

| Method | Description | Effectiveness Against Corrosion |

|---|---|---|

| Hot-dipped Galvanizing | Adds a zinc layer that creates zinc oxide to stop rust. | Very effective due to zinc's protective properties. |

| Coated Steel Plates | G90 or G60 coatings offer different zinc thicknesses; G90 has 0.90 oz/sq ft. | Great for outdoor use with adjustable protection levels. |

Regular Cleaning and Inspection

Cleaning and checking your steel sheet often is important. Dust and moisture can cause rust faster. Wipe the surface with a clean, dry cloth. Look for scratches or damage that might lead to rust. Fix problems quickly to keep the steel in good shape.

Tip: Use rust-proof oils or phosphate coatings for extra safety in humid areas.

Cutting and Bending Techniques

Tools for Cutting

Cutting 18 gauge steel sheets needs the right tools. Use a blade with 24-32 teeth per inch (TPI) for manual cuts. For detailed designs, CNC plasma or laser cutting works best. These tools make smooth edges and protect the steel's quality.

Best Practices for Bending

Bending this steel needs care to avoid cracks. Keep a bend radius of 1T-2T, where T is the sheet's thickness (0.063 inches). Bend at room temperature (60-75°F) for better flexibility. Remember, the steel might spring back slightly, so adjust tools as needed.

| Technique | Details |

|---|---|

| Bending and Folding | Bend without cracking; keep a bend radius of 1T-2T (T = 0.063 inches). |

| Cutting Techniques | Use 24-32 TPI blades; CNC plasma or laser cutting for detailed designs. |

| Forming and Bending | Allow for slight spring-back; bend at 60-75°F for best results. |

Note: Always have trained workers and proper tools to handle steel safely.

Knowing about an 18 gauge steel sheet helps in many industries. Its thickness and material traits affect how it works. It is used in construction, car-making, and appliances. For instance, it strengthens roofs and protects equipment. Cleaning and adding coatings keep it lasting longer. This also lowers repair costs. Learning these details helps you pick the right material, plan better, and save money.

Tip: Check thickness and tolerances with suppliers for your project needs.

FAQ

What is the difference between 18 gauge steel and other gauges?

Gauge measures thickness. An 18 gauge steel sheet is thinner than 16 gauge but thicker than 20 gauge. Thicker sheets provide more strength, while thinner ones are lighter and easier to handle. Choose based on your project’s strength and weight needs.

Can you use 18 gauge steel outdoors?

Yes, you can use it outdoors if it has proper protection. Coatings like galvanization or paint prevent rust and corrosion. Regular maintenance, such as cleaning and inspections, also helps extend its lifespan in outdoor environments.

How do you cut 18 gauge steel sheets?

Use tools like tin snips, power shears, or CNC machines for precise cuts. For manual cutting, select a blade with 24-32 teeth per inch. Always wear safety gear and follow proper cutting techniques to avoid damaging the sheet or injuring yourself.

Is 18 gauge steel suitable for heavy-duty applications?

It depends on the application. While 18 gauge steel offers good strength, thicker gauges like 16 or 14 are better for heavy-duty tasks. Use 18 gauge steel for medium-strength needs, such as automotive panels or HVAC ductwork.

How do you prevent rust on 18 gauge steel?

Apply coatings like galvanization or paint to protect the surface. Regularly clean the steel to remove moisture and dirt. Inspect for scratches or damage that could expose the metal to rust. Use rust-proof oils for added protection in humid areas.

Tip: Always store steel sheets in a dry, covered area to reduce rust risks.